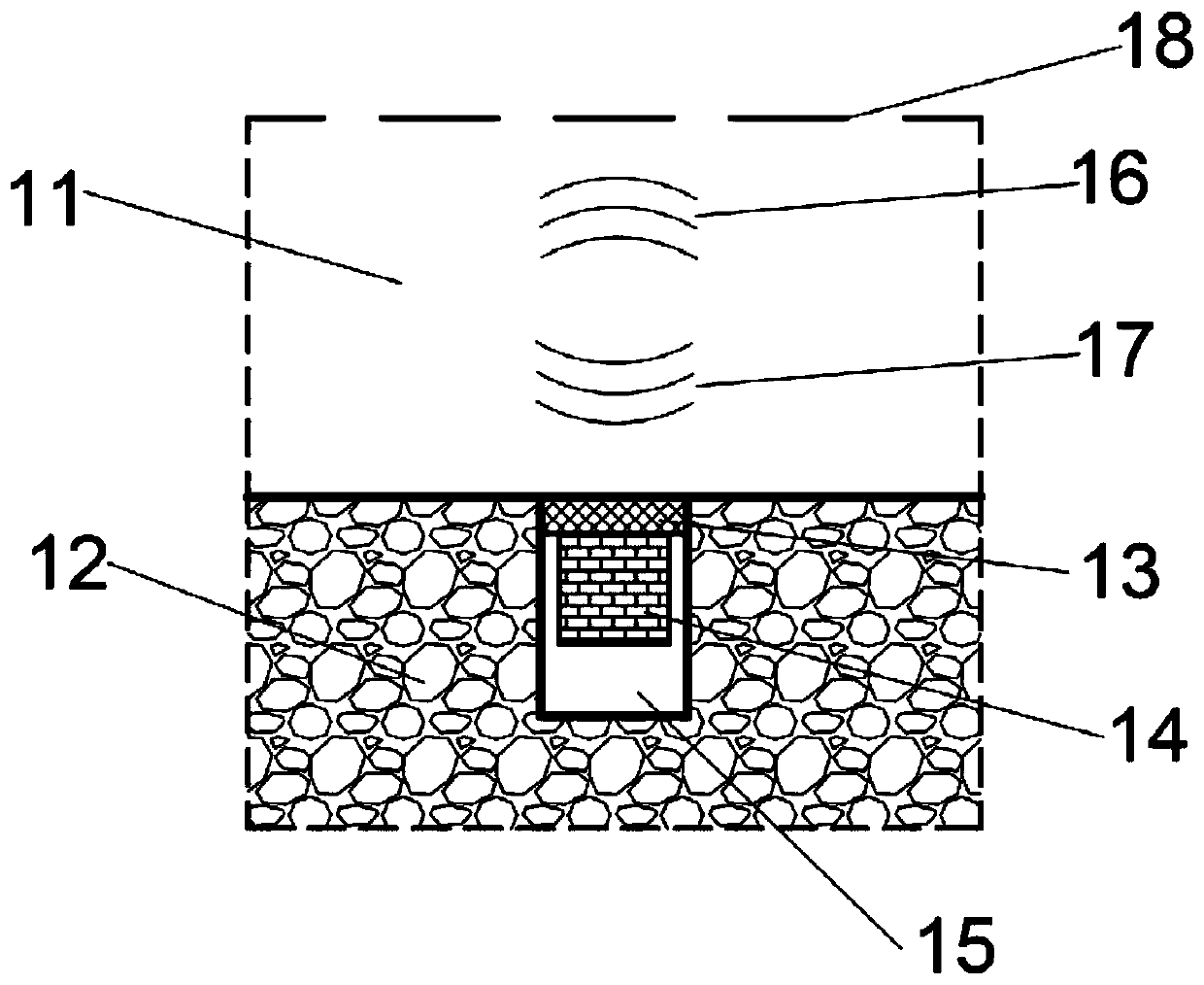

Ultrasonic transducer and nested structure thereof

A technology of ultrasonic transducers and nested structures, which is applied in the direction of instruments, liquid level indicators, machines/engines, etc., can solve the problems that small blind spots and large operating distances cannot be realized at the same time, and achieve short cycle, long transmission distance, The effect of reducing blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

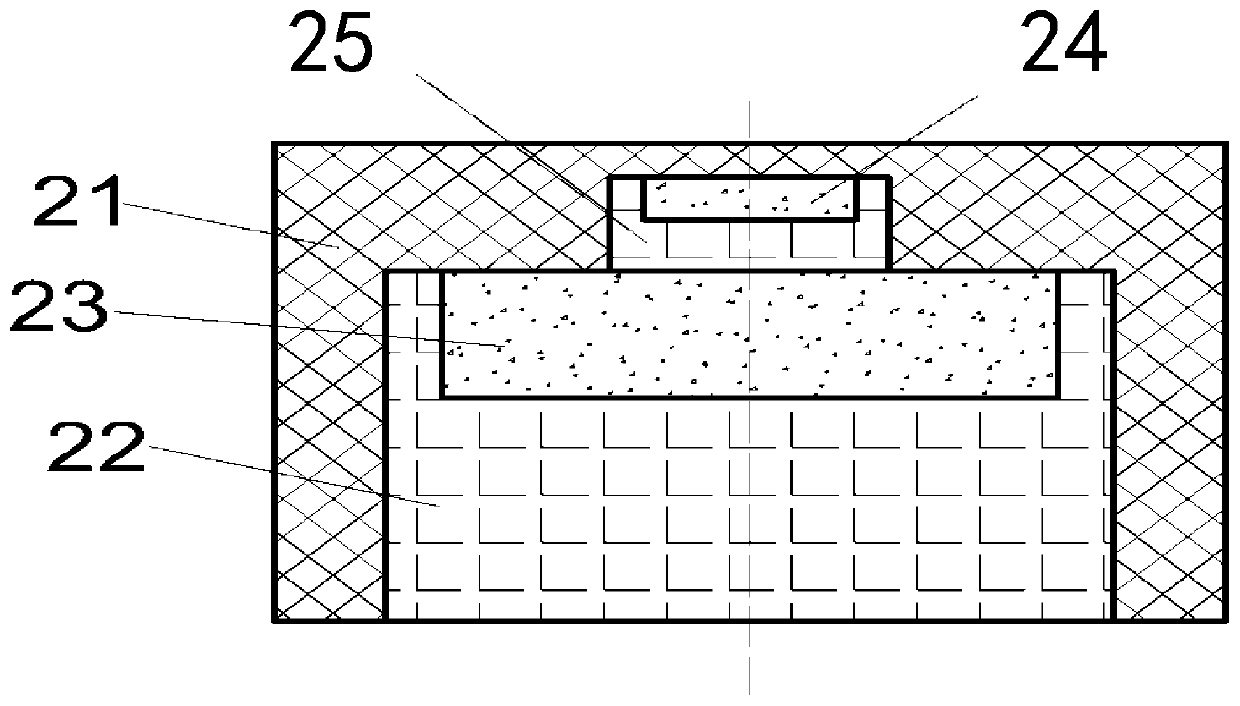

Embodiment 1

[0028] The present invention proposes a nested structure of piezoelectric discs, the cross-sectional structure of which is as follows figure 2 As shown, the nesting structure of the piezoelectric disc includes a housing 21, a cylindrical first filling body 22 is installed at the bottom of the housing 21; a first functional body 23 is installed on the top of the first filling body 22; In the middle of the upper surface of the first functional body 23, an upwardly protruding second filler body 25 is arranged, and a second functional body 24 is arranged on the top of the second filler body 25; in this nested structure, the first functional body 23 A piezoelectric disc with a lower frequency is used; the second functional body 25 adopts a piezoelectric sheet for high-frequency transmission and reception, and the piezoelectric disc and the piezoelectric sheet are both cylindrical structures; and the thickness of the piezoelectric disc is greater than that of the piezoelectric sheet...

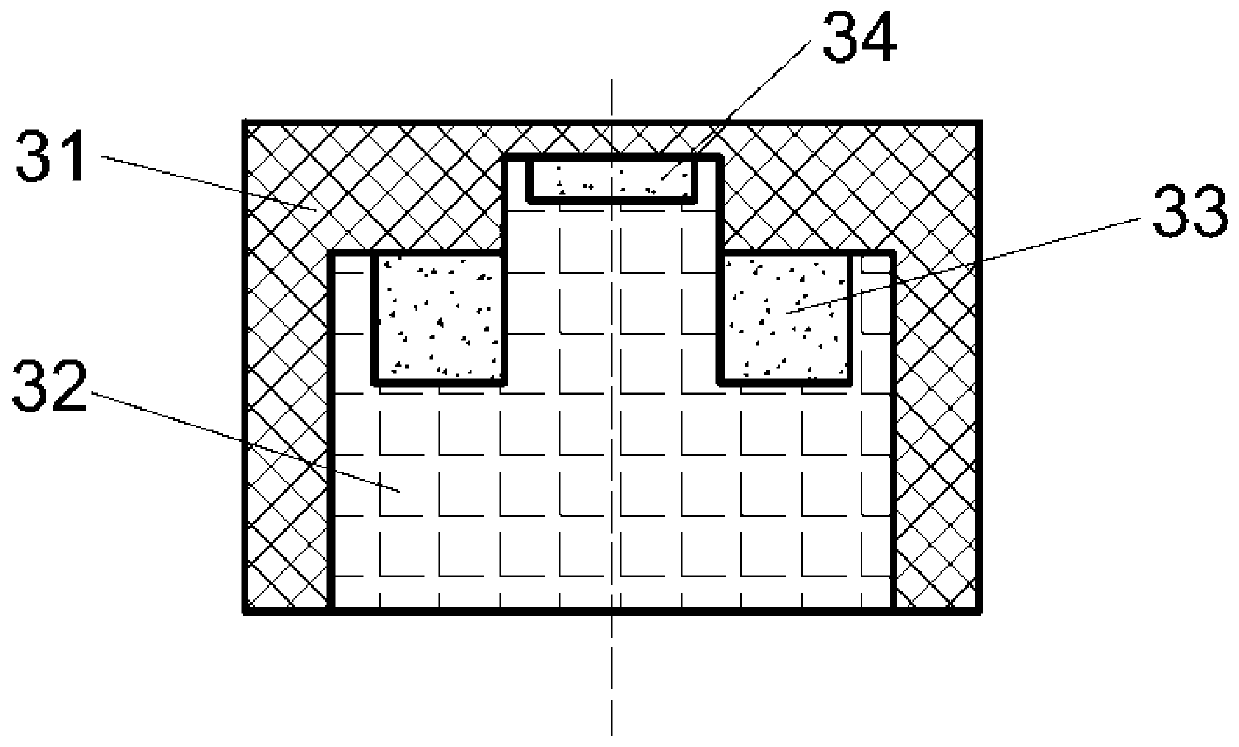

Embodiment 2

[0030] On the basis of Embodiment 1, the present invention proposes a nested structure of piezoelectric rings, the cross-sectional structure of which is as follows image 3 As shown, the nested structure of the piezoelectric ring includes a housing 31, and a convex first filling body 32 is installed at the bottom of the housing 31; A functional body 33; a second functional body 34 is arranged on the upper top of the first filling body 32; in this nested structure, the ring-shaped first functional body 32 adopts a lower frequency piezoelectric ring; the second functional body adopts Piezoelectric sheets for high-frequency transmission and reception; just because the first functional body 32 adopts a piezoelectric ring structure, the first functional body 33 does not directly contact the second filling body. The second filling body 24 is merged with the first filling body 23 to form a convex first filling body 32 in this embodiment; similarly, the thickness of the piezoelectric ...

Embodiment 3

[0032] On the basis of Embodiment 2, the present invention proposes a nested structure of concave cover plates, the cross-sectional structure of which is as follows Figure 4 As shown, the ring-shaped nesting structure includes a downwardly concave shell 41, that is, the cover plate of the shell 41 is a concave cover plate, and a convex first filling body is installed on the bottom of the shell 41. 42; An annular first functional body 43 is installed on the top of both shoulders of the first filling body 42; a second functional body 44 is arranged on the upper top of the first filling body 42; this embodiment adopts a concave cover plate to make the beam Focusing can obtain a narrower beam than the structure of embodiment 2, so that the acoustic energy is more focused and the detection distance is longer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com