10 kv high-voltage circuit breaker electrical test wiring platform based on six-axis mechanical arm

A six-axis robotic arm and high-voltage circuit breaker technology, which is applied to circuit breaker testing, manipulators, program-controlled manipulators, etc., can solve problems such as low work efficiency and high labor intensity, reduce labor intensity, improve test quality, and improve The effect of test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

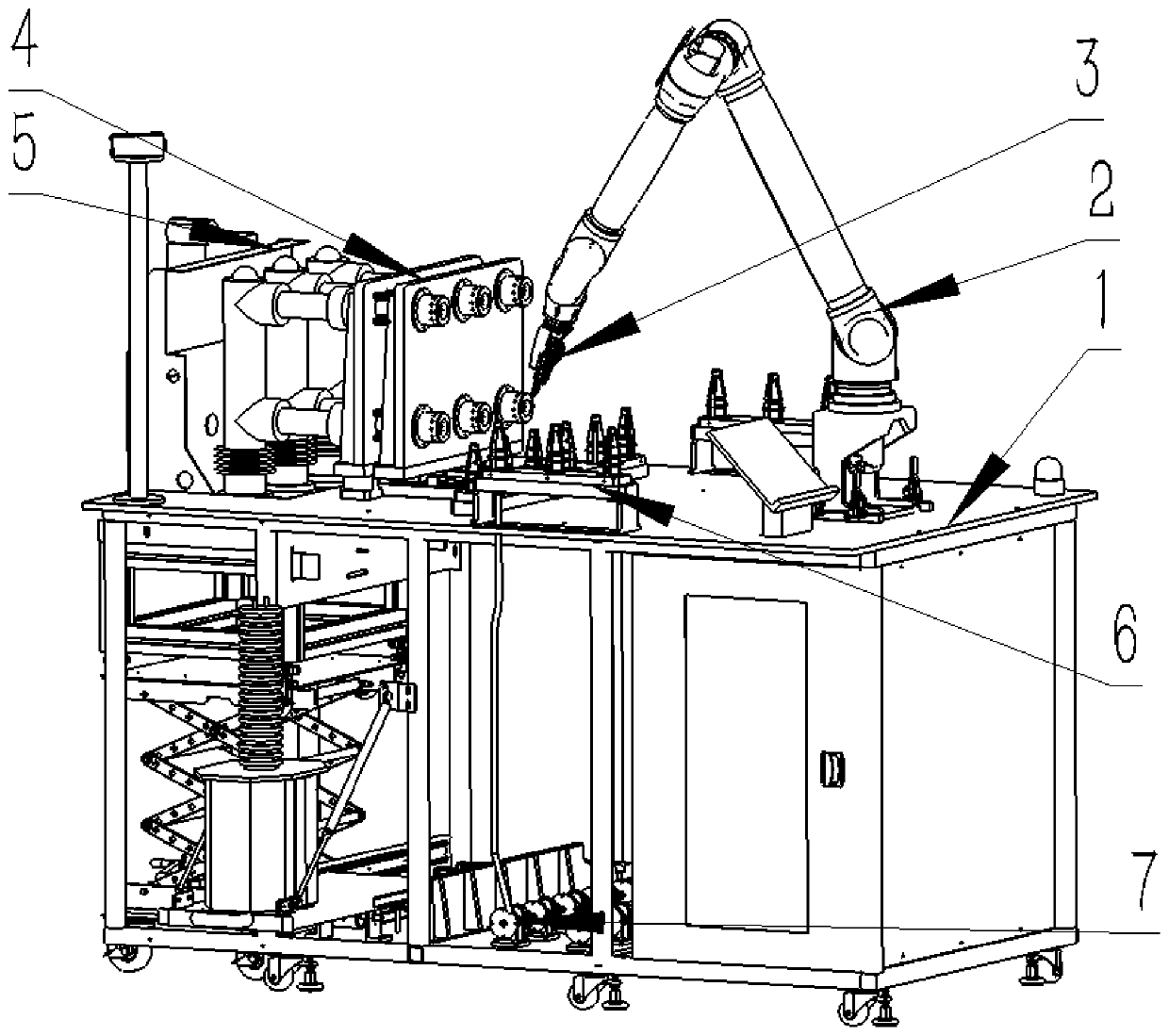

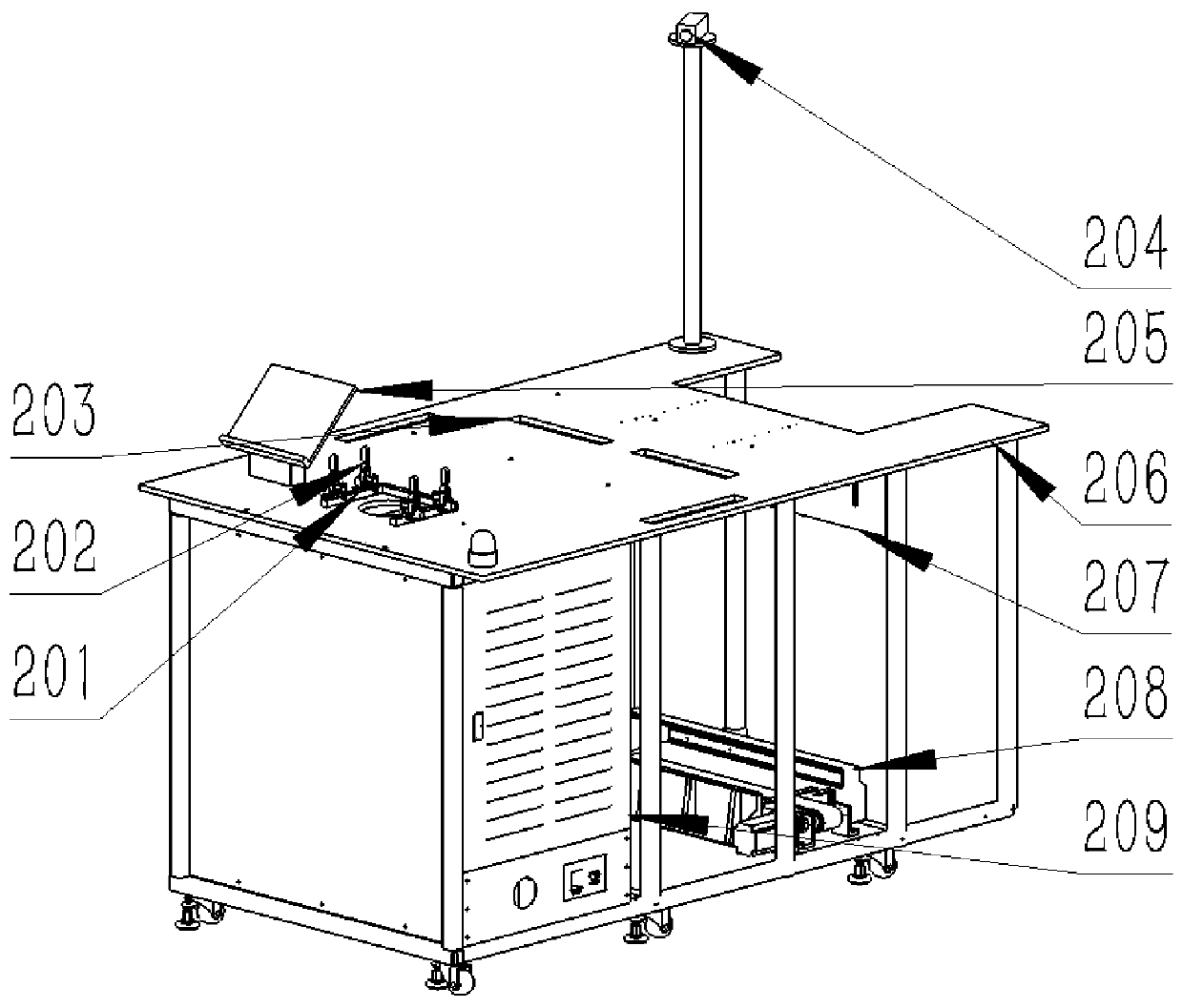

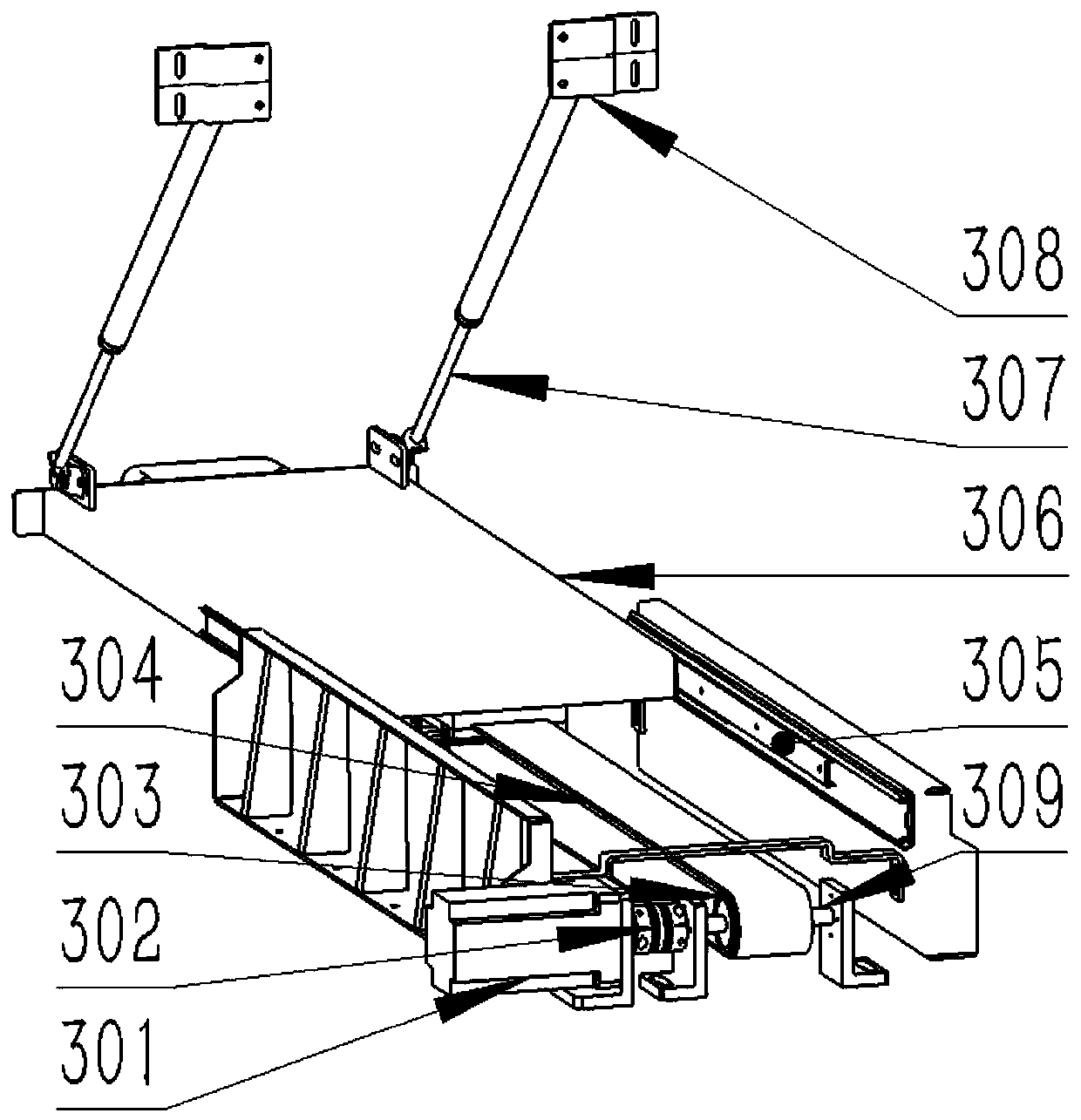

[0032] Such as figure 1 As shown, the 10kv high-voltage circuit breaker electrical test wiring platform based on the six-axis mechanical arm of the present invention includes a test system platform 1, a six-axis mechanical arm 2, a front-end gripper 3, an automatic short-circuit module 4, and a cable positioning module 6. The unwinding module 7, the six-axis mechanical arm 2, the automatic short-circuit module 4, the cable positioning module 6, the unwinding and unwinding module 7 are installed on the test system platform 1, and the front-end gripper 3 is installed on the six-axis mechanical arm 2, the 10kV high-voltage circuit breaker 5 is connected to the test system platform 1 as a whole through a lifting trolley. Position the six-axis robotic arm 2 through the six-axis robotic arm positioning block 201 on the test system platform 1, and then fix the six-axis robotic arm 2 with the quick-installation elbow clamp 202 of the six-axis robotic arm; use the mounting seat 609 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com