Converter valve air cooler fault positioning method

A technology for fault location and air coolers, applied in instruments, complex mathematical operations, measuring devices, etc., can solve problems such as rotor imbalance, bearing inner and outer ring pitting, bearing ball wear, etc., to avoid serious accidents, reduce maintenance costs, and guarantee The effect of fault accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

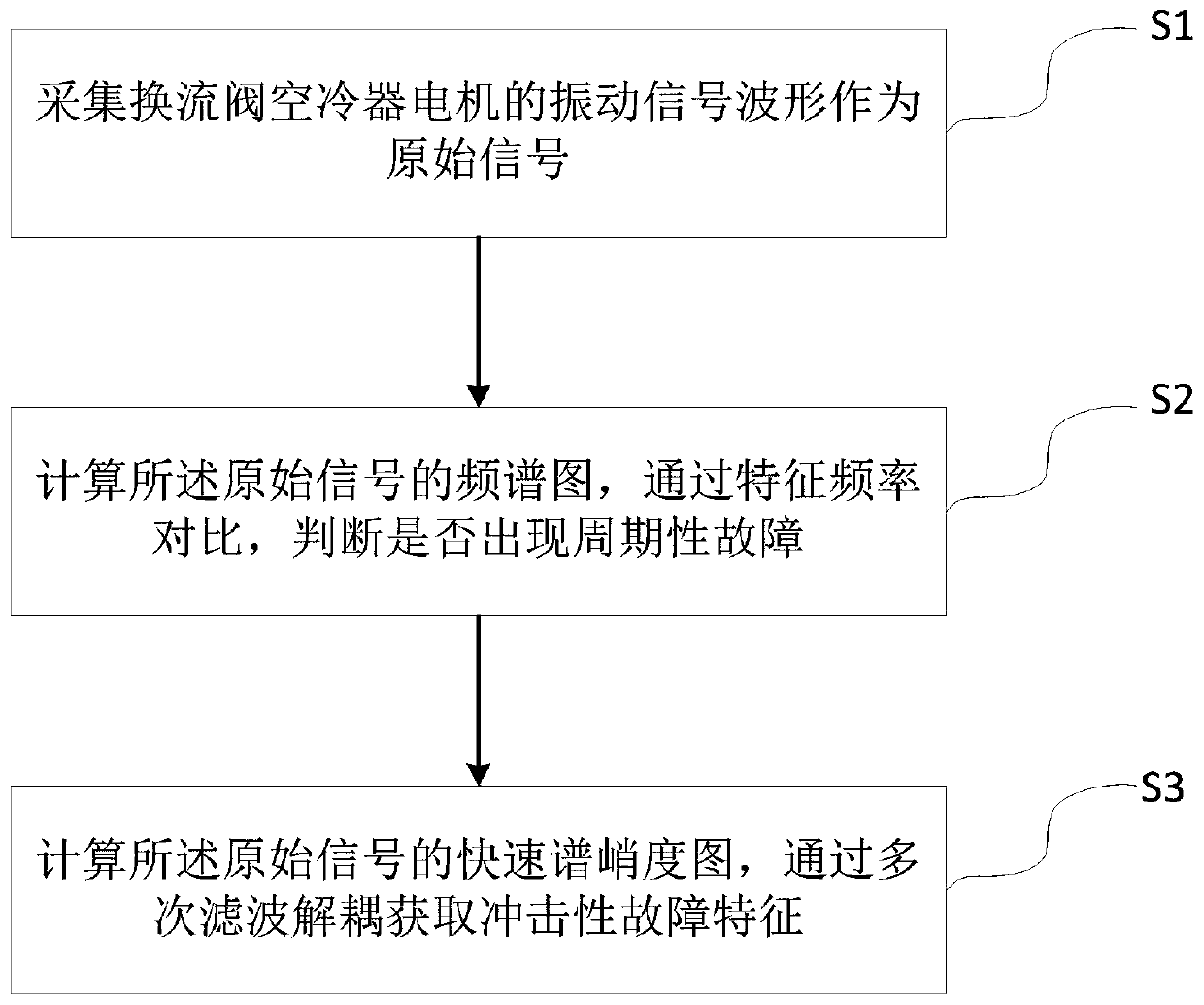

Method used

Image

Examples

Embodiment 1

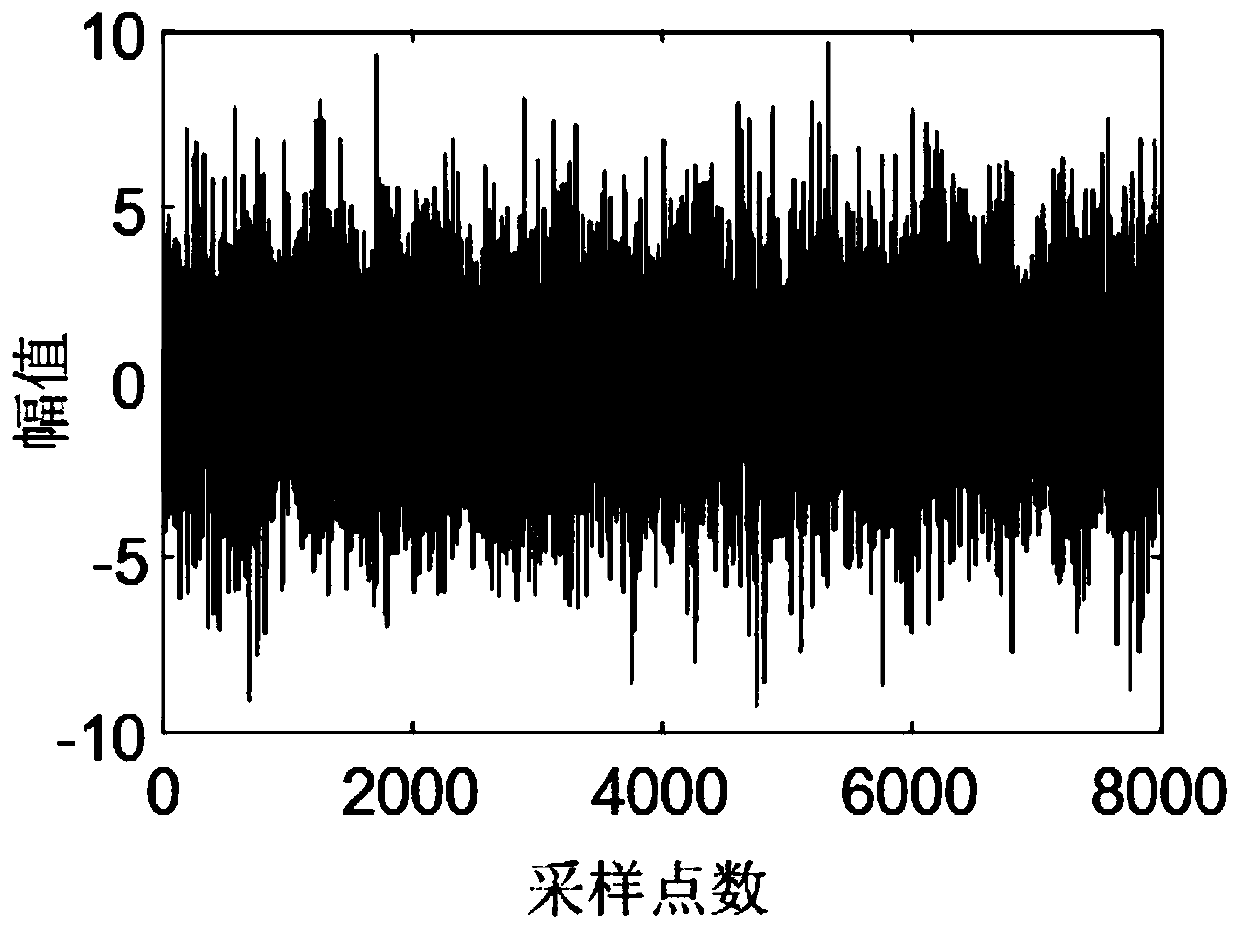

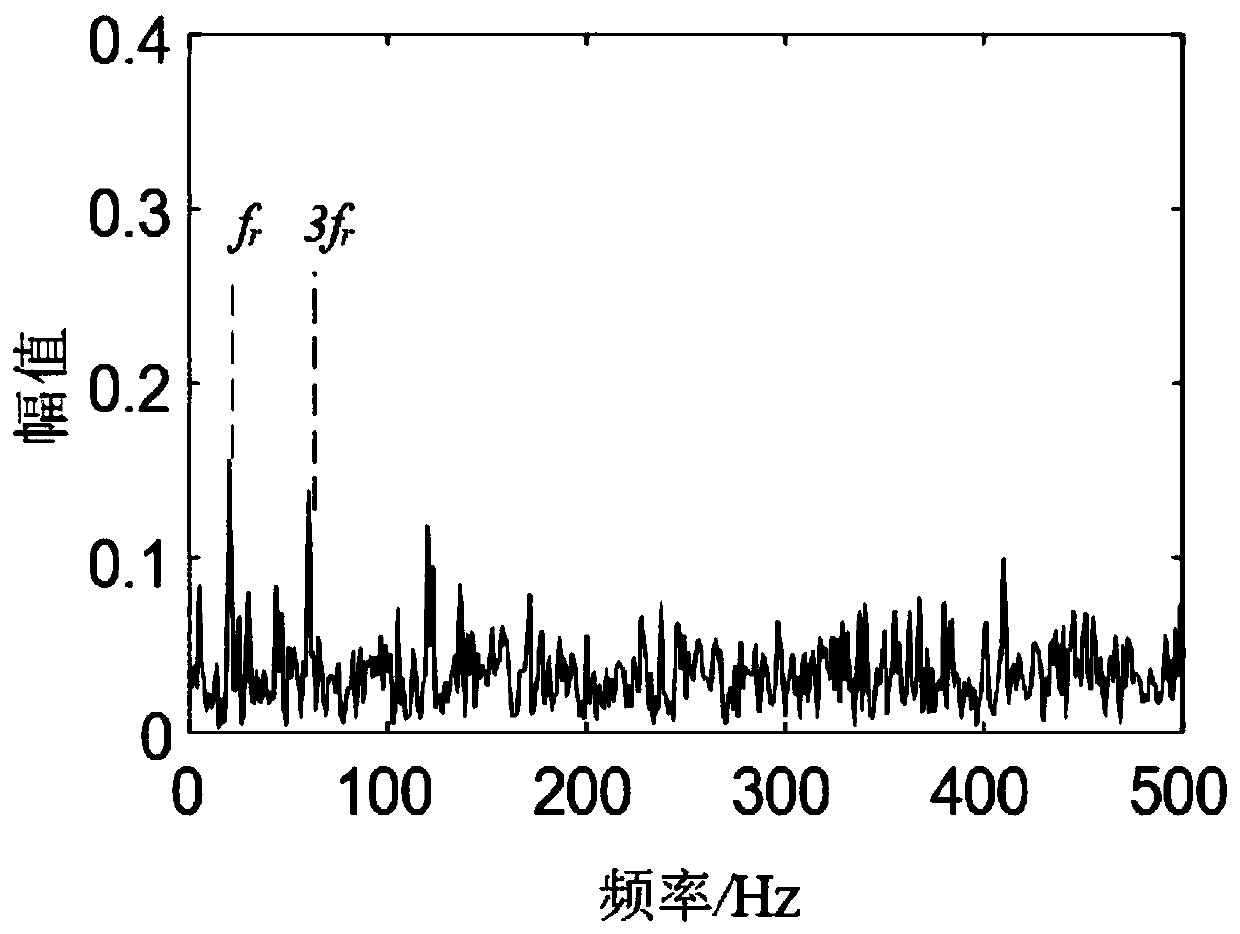

[0063] The following is an example of the early composite fault separation of the converter valve air cooler motor. A magnetic vibration sensor is used to collect vibration signals, the sampling frequency is 10000 Hz, the sampling length is 8k points, and the motor rotation frequency is 20 Hz. The fault characteristic frequency of the periodic fault is 3 times the frequency, the fault frequency of the impulse fault 1 is about 160.2Hz, and the fault characteristic frequency of the impulse fault 2 is 105.9Hz.

[0064] Firstly, the bearing vibration signal x(t) is measured by the magnetic vibration sensor, such as figure 2 shown. Use steps 2 and 3 to calculate the spectrum of the low-frequency part of the original signal, and perform spectrum analysis, such as image 3 shown.

[0065] Use step 4 to calculate the fast spectral kurtosis map of the original signal, as Figure 4 shown.

[0066] Select the color block with the largest kurtosis in the fast spectral kurtosis diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com