Electrical equipment maintenance site safety isolation method

A technology of electrical equipment and safety isolation, applied in instruments, information technology support systems, building structures, etc., can solve the problem that energy isolation and orderly management cannot be effectively and effectively achieved, the work schedule of the maintenance team is uncertain, and the rigid constraints of management measures are lacking. and other problems, to achieve order and standardization, prevent the loss of energy isolation keys, and achieve the effect of humanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

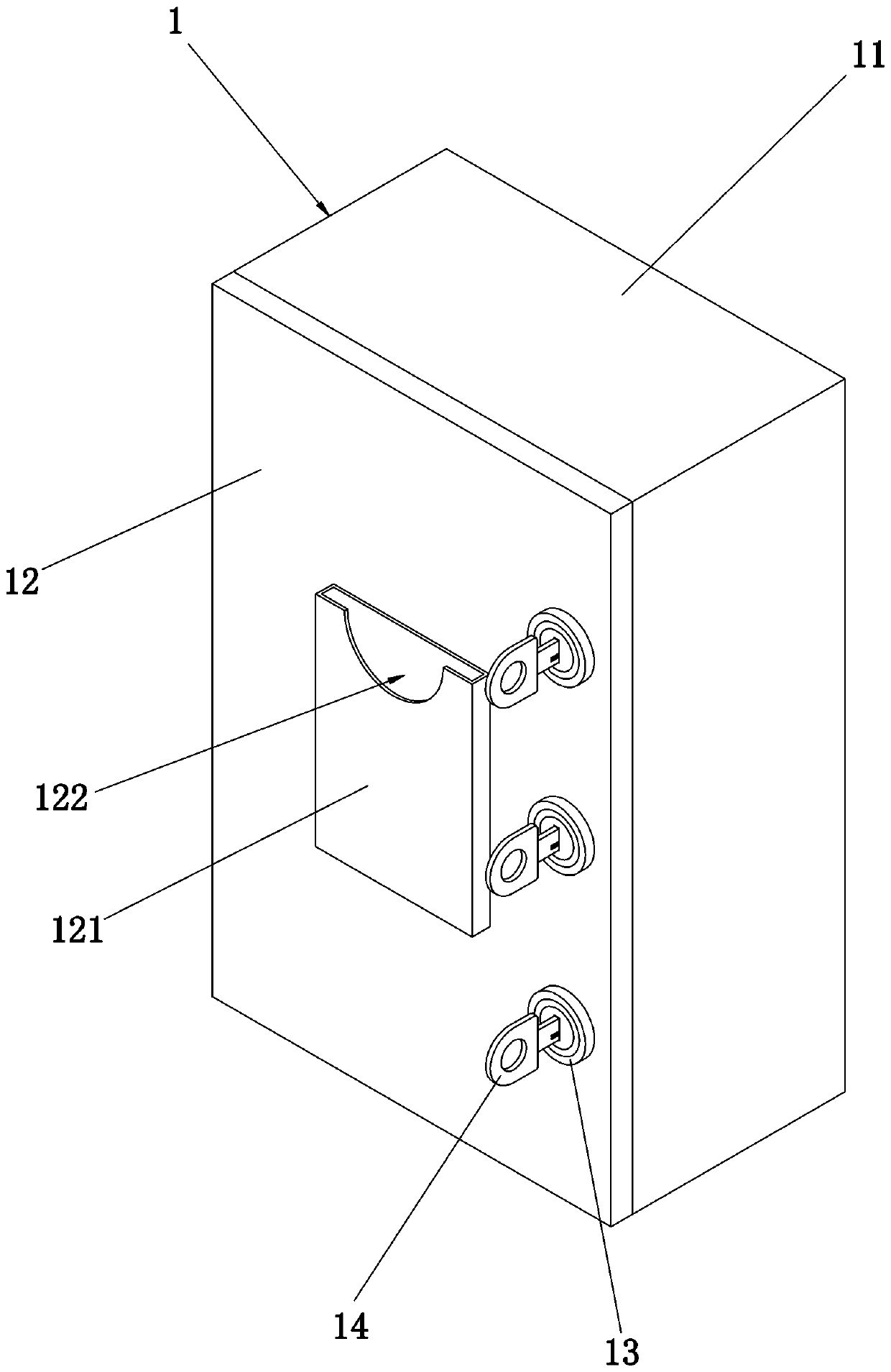

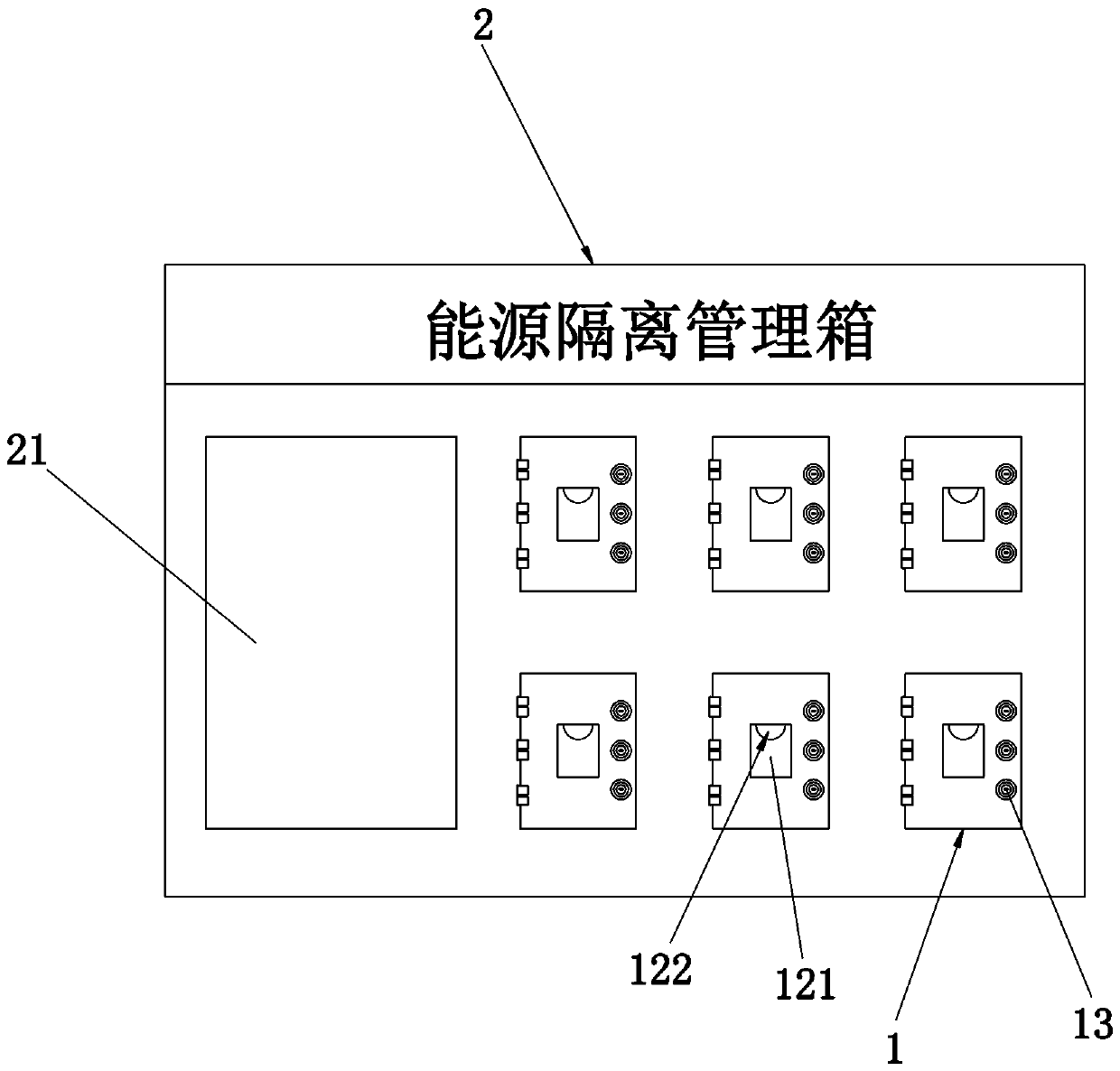

[0027] refer to figure 1 with figure 2 , an energy isolation management box, including at least one isolation box 1 for placing energy isolation keys, the isolation box 1 includes a box body 11, the box body 11 is hinged with a box door 12, and is equipped with several 12 is locked in the safety lock 13 and the safety key 14 of the casing 11.

[0028] refer to figure 1 with figure 2 The energy isolation management box also includes a fixed plate 2 that can be hung on the wall, a publicity area 21 is provided on the left side of the fixed plate 2, and several isolation boxes 1 are arranged in a row on the right side. Several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com