A noise reduction motor unit for lifting and its production method

A unit, noise-electric technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of lifting motor unit noise, affecting the use, etc., to achieve a good clamping effect, reduce the possibility of water ingress, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

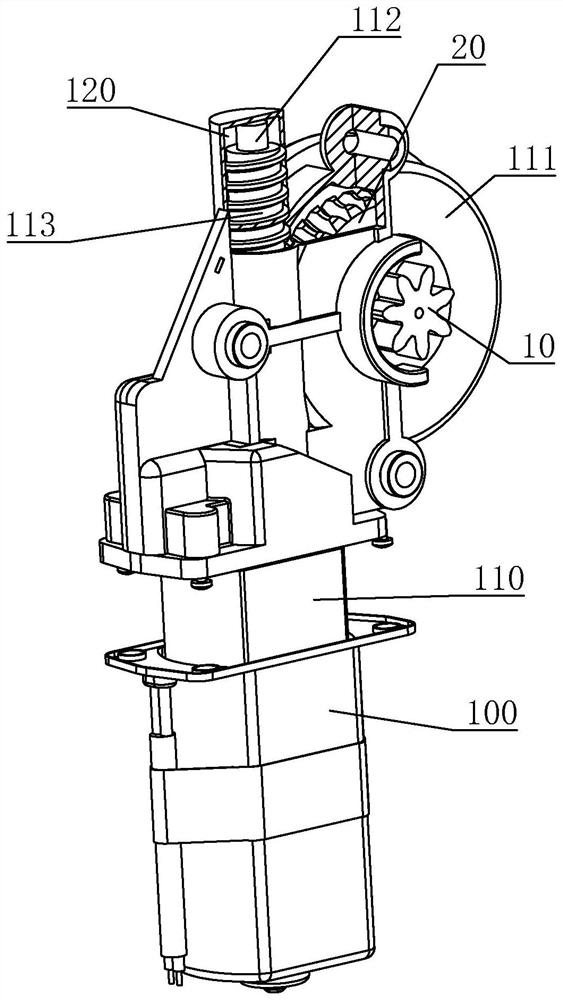

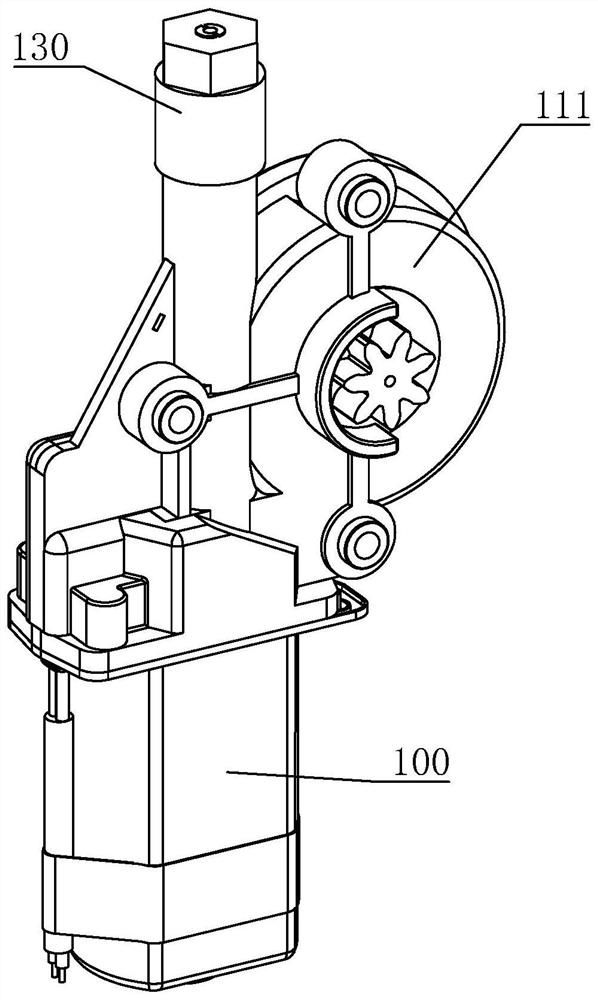

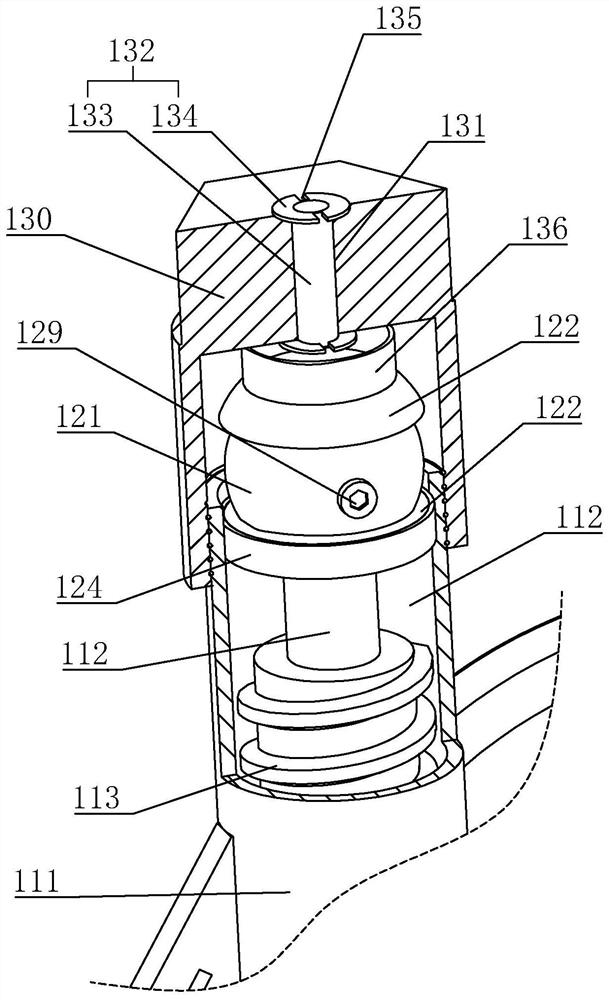

[0043] A noise reduction motor unit for lifting, referring to figure 2 , image 3, comprising a motor base 100, a motor body 110, and a reduction box 111, the motor base 110 is installed in the motor base 100, the motor base 100 and the reduction box 111 are connected by bolts, and the output shaft 112 of the motor body 110 is integrally formed There is a worm 113, the reduction box 111 has a rotating chamber 120 for the worm 113 to rotate, the end of the output shaft 112 is provided with a rotating ball 121, and the rotating chamber 120 is provided with two bearing sleeves 122 for being close to the rotating ball 121 , the two bearing sleeves 122 are used to limit the rotating ball 121 in the axial and radial directions.

[0044] refer to image 3 , Figure 4 Firstly, the rotating ball 121 and the output shaft 112 are arranged separately, and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com