Radiator with fins capable of being opened and closed in self-adaptive mode along with temperature

A temperature-dependent, self-adaptive technology, used in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc. Dust-proof and anti-collision effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

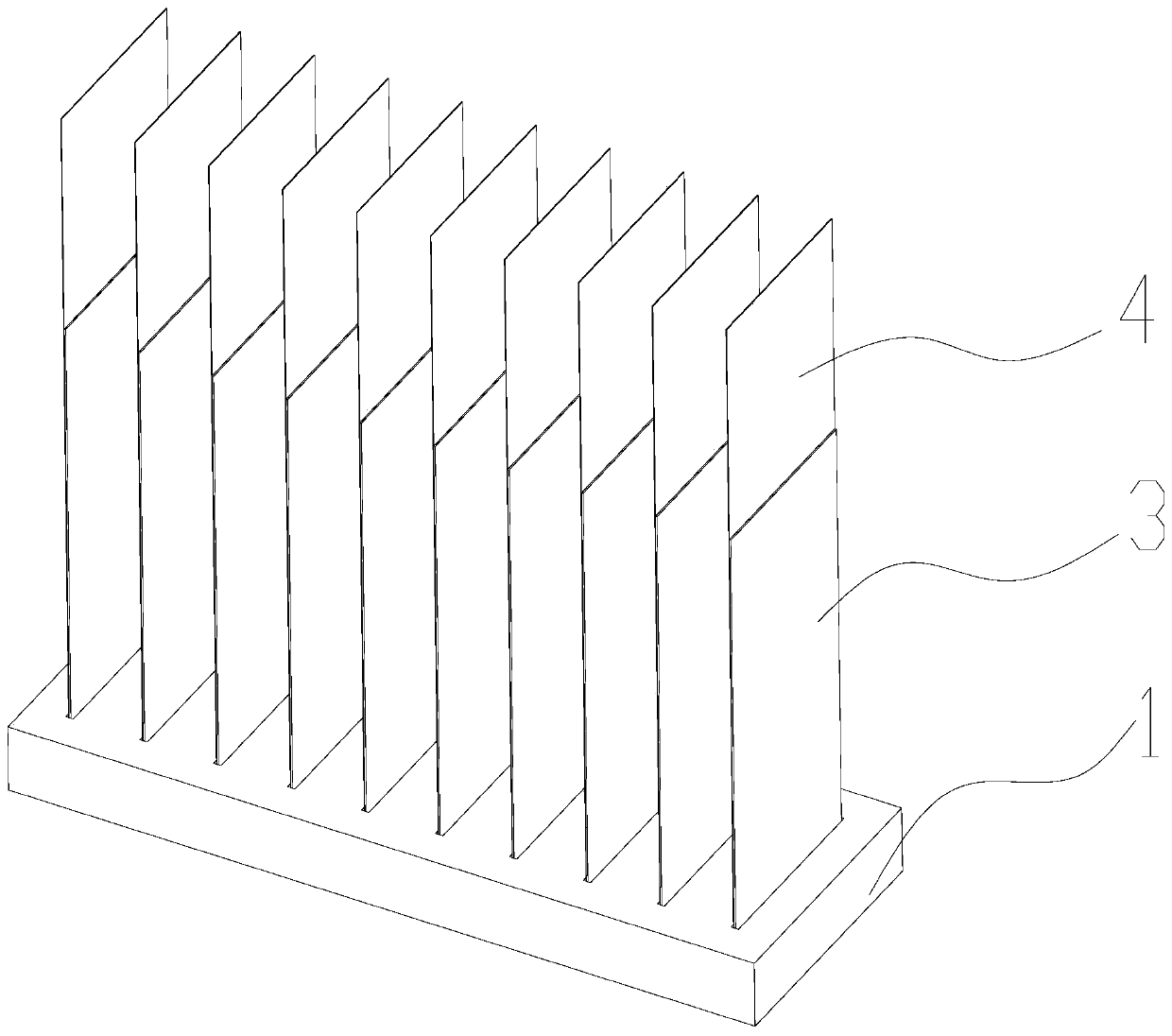

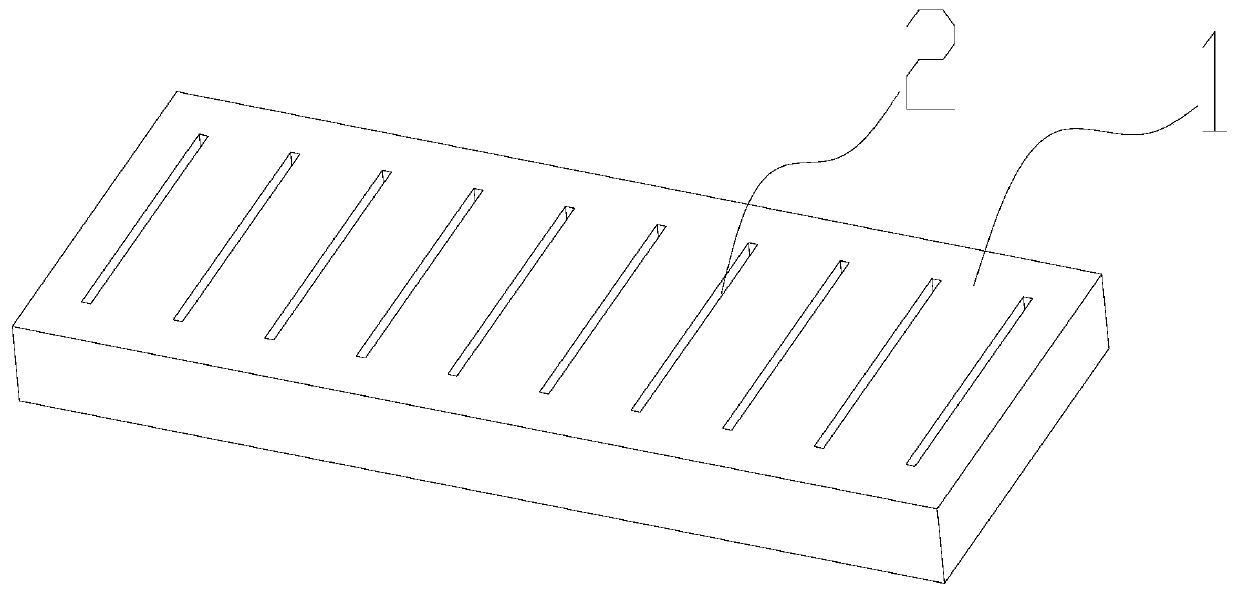

[0030] Such as figure 1 and figure 2 As shown, this embodiment provides a heat sink with fins that expand and close adaptively with temperature, including a base 1 and a heat dissipation assembly.

[0031] Such as figure 1 , figure 2 and image 3 As shown, the bottom surface of the base is provided with a heat source, and the top surface of the base is provided with a plurality of installation slots 2, the installation slots are square, the size is 1mm×25mm×3mm, the distance between the center lines of the two slots is 10mm, and the installation slots are equipped with tin Paste, each mounting slot is provided with a group of heat dissipation components, the distance between two adjacent groups of heat dissipation components is 10mm, the heat dissipation components include shape memory alloy parts 3 and heat dissipation fins 4, and the shape memory alloy parts and heat dissipation fins are both sheet-shaped , the size of the heat dissipation fin is 25mm×60mm, the size of...

Embodiment 2

[0035] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the heat sink with self-adaptive opening and closing fins with temperature also includes a plurality of clamping parts 5 and limiting parts 6, and the clamping parts are placed on the base On the top surface, two adjacent clamping parts jointly clamp the root of the shape memory alloy part and the root of the cooling fin. The limiting part is U-shaped, and the limiting part includes a connecting rod 61 and a fixing rod 62. The two ends of the connecting rod They are respectively connected to the fixed rods, the connecting rods are crimped to the top surfaces of multiple clamping parts from top to bottom, the fixed rods are fixed to the end face of the base through bolts 7, and the length of the base along the axial direction is the same as that of the multiple clamping parts along the axis. The lengths arranged in the same direction are equal to the lengths of the connecting rods...

Embodiment 3

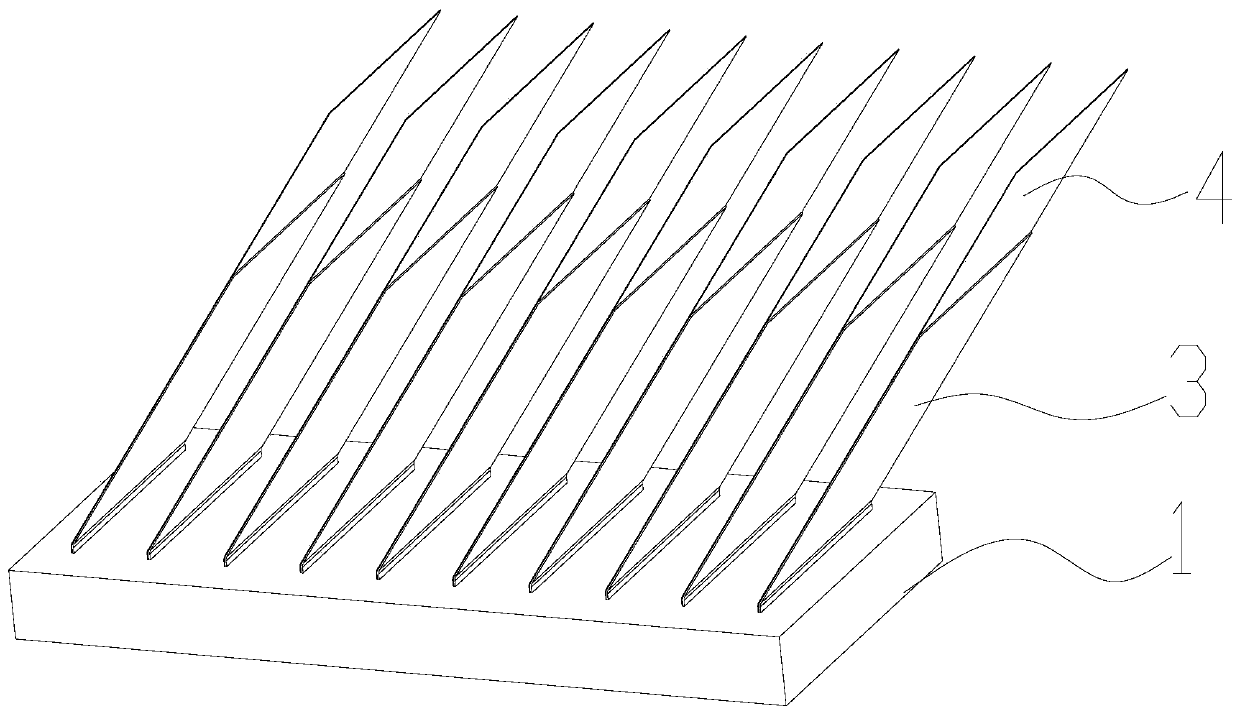

[0037] Such as Figure 5 and Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the heat dissipation fins and shape memory alloy parts are respectively folded in half along the middle, and the head and tail ends of the heat dissipation fins and shape memory alloy parts are respectively fixed in the installation grooves, and the shape memory The alloy parts are located inside the cooling fins. After folding the cooling fins and shape memory alloy parts in half, the upper and lower parts folded in half are attached at low temperature. As the temperature rises, the shape memory alloy parts inside the cooling fins begin to deform, and the cooling fins are gradually opened. Increase the contact area between the cooling fins and the air. At the same time, compared with the case where the cooling fins and the shape memory alloy parts are not folded in half, the heat dissipation area of the cooling fins after folding is increased by one when the ini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com