Manufacturing method of eddy current conformal cooling water channel based on metal 3D printing

A conformal cooling and 3D printing technology, which is applied in the field of mold manufacturing, can solve problems such as the influence of mold structure strength and precision, high manufacturing difficulty, and complex shape, and achieve the effects of improving heat dissipation, reducing collapse, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

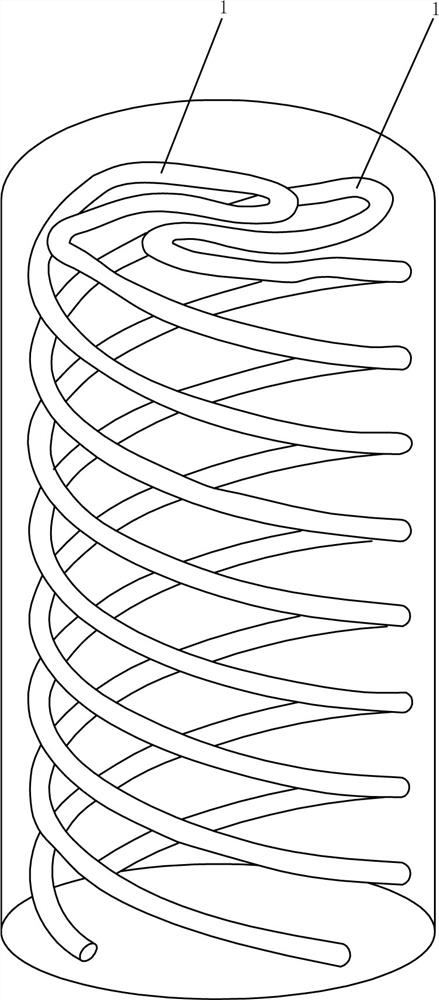

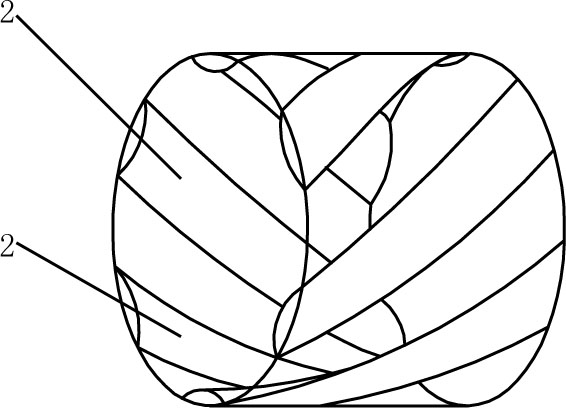

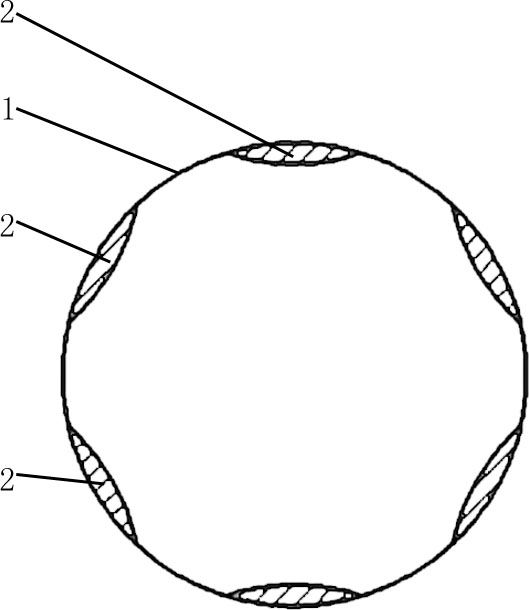

[0039] Such as Figure 1-3 The shown eddy current conformal cooling waterway based on metal 3D printing includes two spiral cooling water channels 1 arranged on the mold body. The spiral cooling water channel 1 has a water inlet and a water outlet, and the two spiral cooling water channels 1 are arranged in parallel according to the same spiral direction; the inner wall of the spiral cooling water channel 1 is provided with a strip-shaped heat dissipation unit protruding toward the inner cavity of the spiral cooling water channel 1, and the strip-shaped heat dissipation unit moves forward according to the spiral direction of the spiral cooling water channel 1 The outlet to which the spout extends.

[0040] The strip heat dissipation unit includes six riflings 2 protruding from the inner wall of the spiral cooling water channel 1 , and each rifling 2 is distributed along the circumferential direction of the spiral cooling water channel 1 .

[0041] In the above-mentioned eddy ...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 is: as Figure 4 As shown, the cross section of the rifling 2' is trapezoidal.

Embodiment 3

[0058] The difference between this embodiment and embodiment 1 is: as Figure 5 As shown, the rifling 2" has a rectangular cross-section.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com