Electric vehicle power system and mine car

A technology for electric vehicles and power systems, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of difficulty in going uphill for mining vehicles and difficulty in shifting gears when going uphill, achieving high reliability and overcoming difficulties in shifting gears , Increase the effect of torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

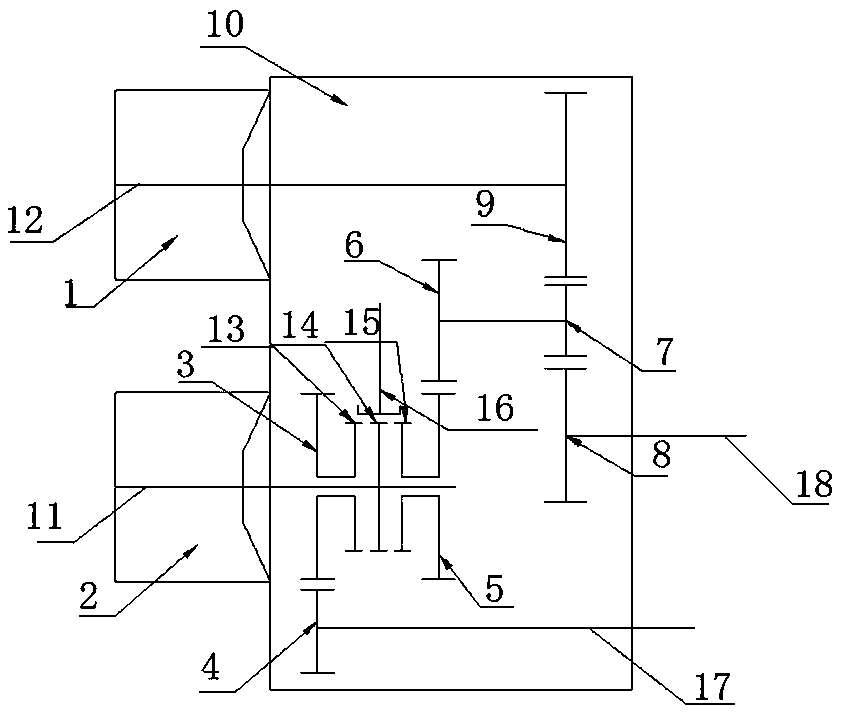

[0028] Specific embodiments of the electric vehicle power system provided by the present invention: the electric vehicle power system is mainly used in mining vehicles, such as figure 1 As shown, it includes a first power motor 1 , a second power motor 2 , a speed reducer 10 and a power take-off. The first power motor 1 and the second power motor 2 are in parallel mode and connected to the speed reducer 10 respectively. Among them, the first power motor 1 is connected with the first input shaft 12 of the reducer 10 through a spline shaft; the second power motor 2 is connected with the second input shaft 11 of the reducer 10 through a spline shaft, and the reducer 10 is connected by its power The output shaft 18 is connected to a downstream drive system. In this embodiment, the rated speed of the first power motor 1 is greater than the rated speed of the second power motor 2, and is mainly responsible for providing high speed for the mine car. Since there are few working condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com