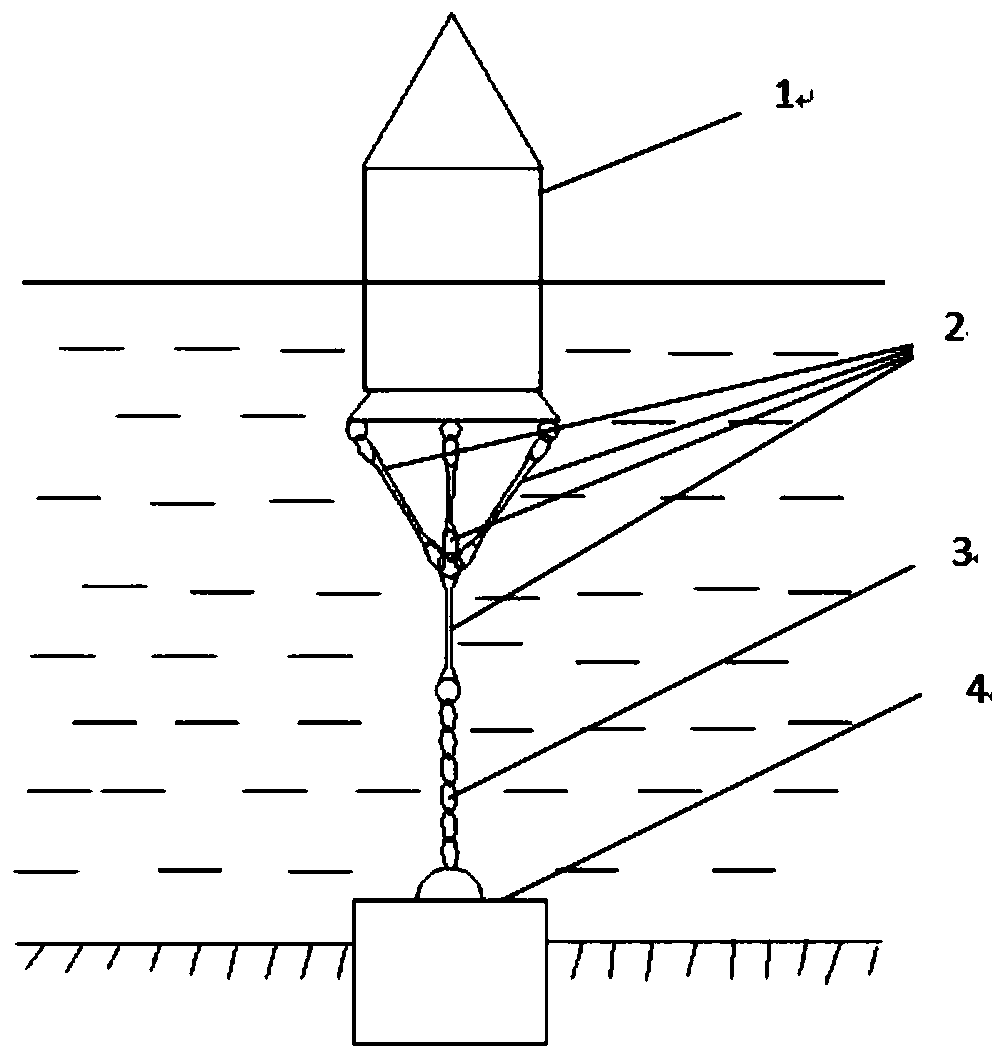

Hybrid mooring navigation mark system and manufacturing method of synthetic mooring rope

A production method and synthetic technology, applied in the direction of buoys, textile cables, special-purpose ships, etc., can solve the problems of easy corrosion, self-heavy anchor chains, weak wave energy absorption, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

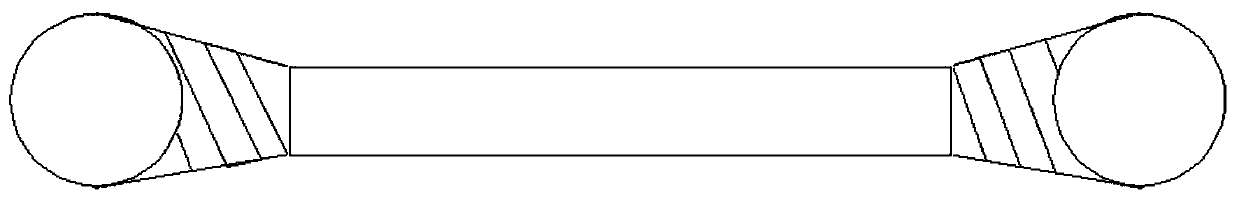

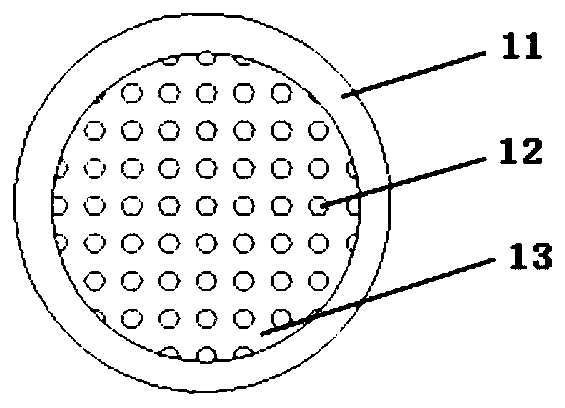

[0033] How to make synthetic mooring ropes:

[0034] Heat setting pretreatment step: weave a single white 840D nylon 66 yarn into a cylinder through a knitting machine, so as to facilitate the subsequent use of steamed yarn;

[0035] Heat setting step: place the above-mentioned cylindrical yarn in a steaming machine, set the steam temperature to 150°C, and set the heat setting treatment time to 8 hours;

[0036] Winding step: wind the heat-set white 840D nylon 66 yarn onto paper tubes, and prepare 30 paper tubes in total;

[0037] Steps for making rope yarn: Twisting and threading 30 white 840D nylon 66 yarns to form a rope yarn, the twisting directions are S direction and Z direction respectively, and three groups of rope yarns are prepared for each twist direction;

[0038] Rope core making step: reversely twist and thread the three rope yarns in the same twist direction in the above steps to form a rope core, and the directions of reverse twisting are Z direction and S dir...

Embodiment 2

[0050] How to make synthetic mooring ropes:

[0051] Heat setting pretreatment step: weave a single white 840D nylon 66 yarn into a cylinder through a knitting machine, so as to facilitate the subsequent use of steamed yarn;

[0052] Heat setting step: place the above-mentioned cylindrical yarn in a steaming machine, set the steam temperature to 180°C, and set the heat setting treatment time to 7.5 hours;

[0053]Winding step: wind the heat-set white 840D nylon 66 yarn onto paper tubes, and prepare 40 paper tubes in total;

[0054] Steps for making rope yarn: Twisting and threading 40 white 840D nylon 66 yarns to form a rope yarn, the twisting directions are S direction and Z direction respectively, and three groups of rope yarns are prepared for each twist direction;

[0055] Rope core making step: reversely twist and thread the three rope yarns in the same twist direction in the above steps to form a rope core, and the directions of reverse twisting are Z direction and S di...

Embodiment 3

[0067] How to make synthetic mooring ropes:

[0068] Heat setting pretreatment step: weave a single white 840D nylon 66 yarn into a cylinder through a knitting machine, so as to facilitate the subsequent use of steamed yarn;

[0069] Heat setting step: place the above-mentioned cylindrical yarn in a steaming machine, set the steam temperature to 200°C, and set the heat setting treatment time to 5 hours;

[0070] Winding step: wind the heat-set white 840D nylon 66 yarn onto paper tubes, and prepare 30 paper tubes in total;

[0071] Steps for making rope yarn: Twisting and threading 30 white 840D nylon 66 yarns to form a rope yarn, the twisting directions are S direction and Z direction respectively, and three groups of rope yarns are prepared for each twist direction;

[0072] Rope core making step: reversely twist and thread the three rope yarns in the same twist direction in the above steps to form a rope core, and the directions of reverse twisting are Z direction and S dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com