An energy-saving sewage treatment device

A sewage treatment device and water inlet pipe technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of reducing the mixing effect, sedimentation efficiency, and static sedimentation efficiency Low, unfavorable large-scale treatment of sewage and other issues, to achieve the effect of improving the mixing effect and sedimentation efficiency, reducing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

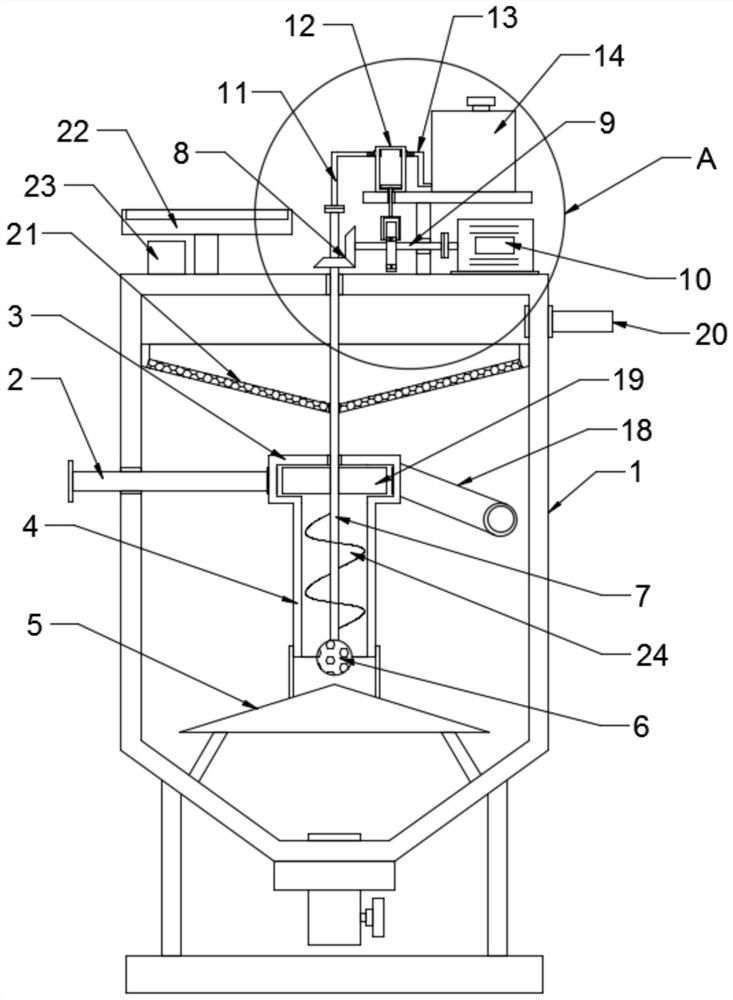

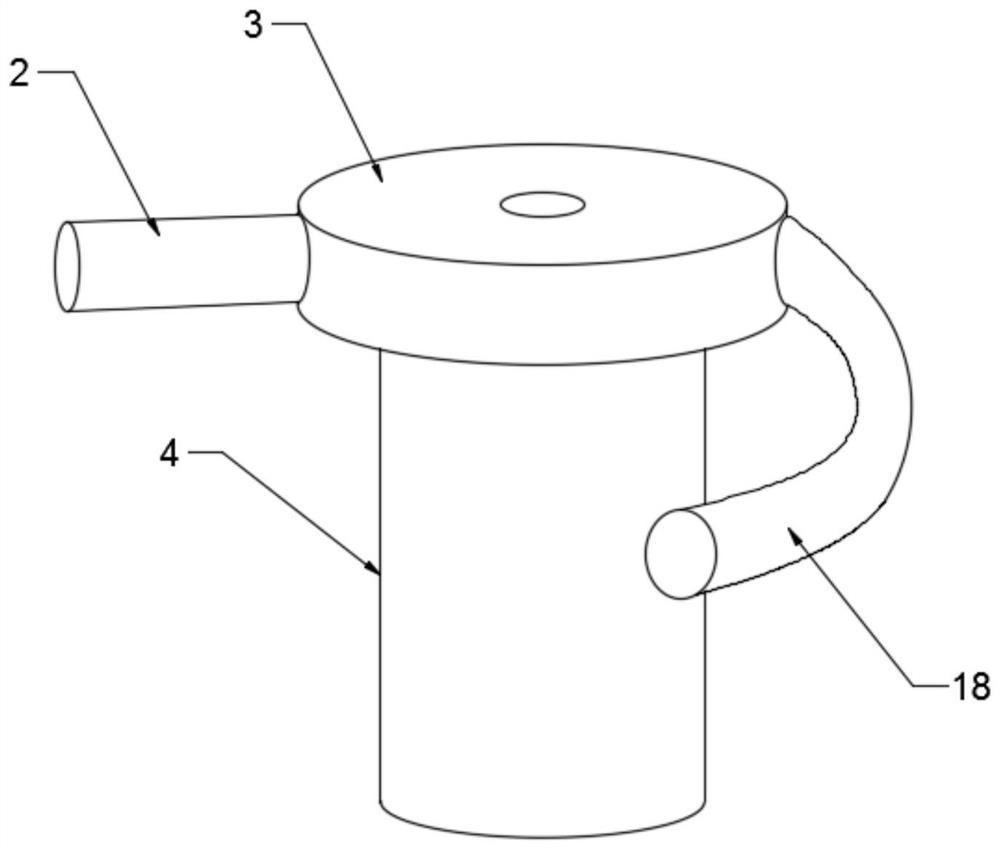

[0021] see Figure 1-5 In an embodiment of the present invention, an energy-saving sewage treatment device includes a tank body 1; a water inlet pipe 2 is provided on one side of the tank body 1, and the water inlet pipe 2 extends into the tank body, and the end of the water inlet pipe 2 is fixedly connected with a diffusion cylinder 3 , the water inlet pipe 2 is in tangential communication with the inner cavity of the diffusion cylinder 3, the sewage flows into the diffusion cylinder 3 tangentially, and the right side of the diffusion cylinder 3 is fixedly connected with a diversion elbow 18, and the diversion elbow 18 extends to the inner wall of the tank body 1; The diffusion cylinder 3 is nested with impeller plates 19 distributed in a circle, and the outer end of the impeller plate 19 abuts and slides against the inner wall of the diffusion cylinder 3; the impeller plate 19 is fixedly connected with the hollow shaft 7, specifically, the sewage enters the In the diffusion ...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that in order to improve the sewage precipitation effect, the upper part of the tank body 1 is provided with an outlet pipe 20, and the inner wall of the tank body 1 is fixedly connected with a conical filter screen 21. The bottom and the surface are evenly opened with a conical net cover with mesh holes to filter the sewage discharged from the overflow. At the same time, under the action of the sewage swirl, the water flow continuously scours the lower end surface of the conical filter screen 21 to avoid clogging of the filter mesh and improve the filtration efficiency. Efficiency, to ensure the filtering effect.

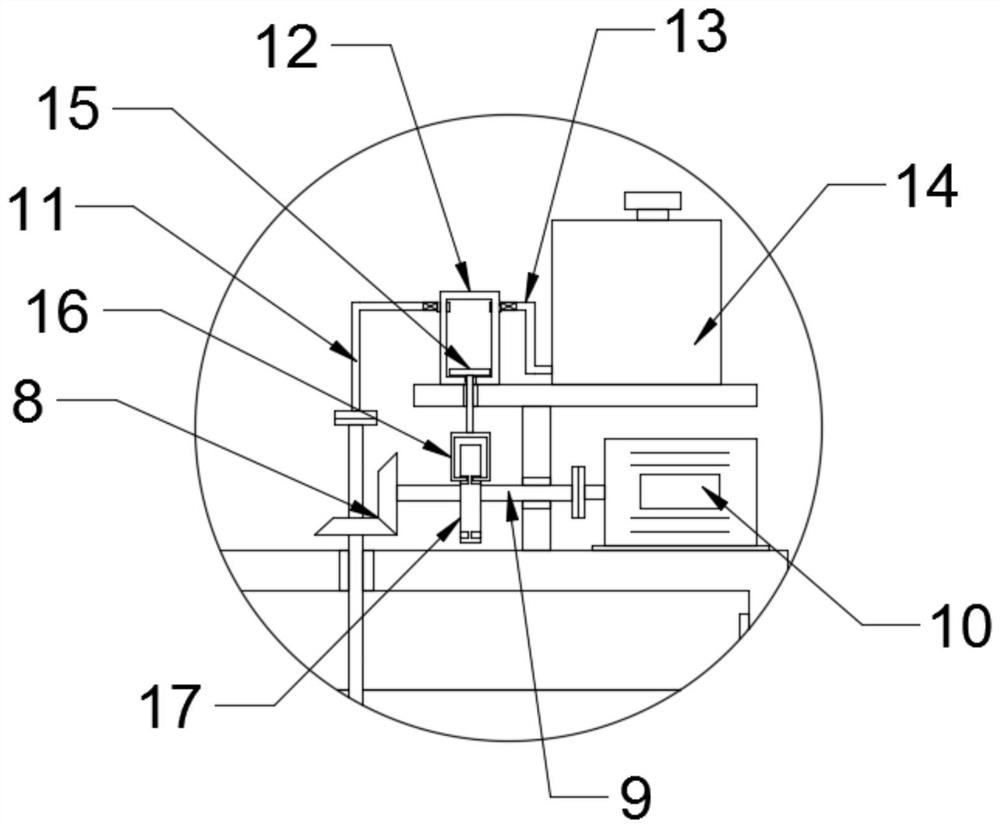

[0027] In order to simplify the driving mechanism, the liquid supply mechanism includes a pumping piston cylinder 12 and a liquid medicine tank 14, the liquid suction piston cylinder 12 communicates with the liquid medicine tank 14 through a liquid suction pipe 13, and the liquid flocculant is filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com