Dry anaerobic fermentation biogas manufacturing system and biogas manufacturing method for wet garbage

A dry anaerobic fermentation and waste technology, applied in specific-purpose bioreactors/fermenters, fermentation, anaerobic digestion, etc. Problems such as reduced speed and small amount of water added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

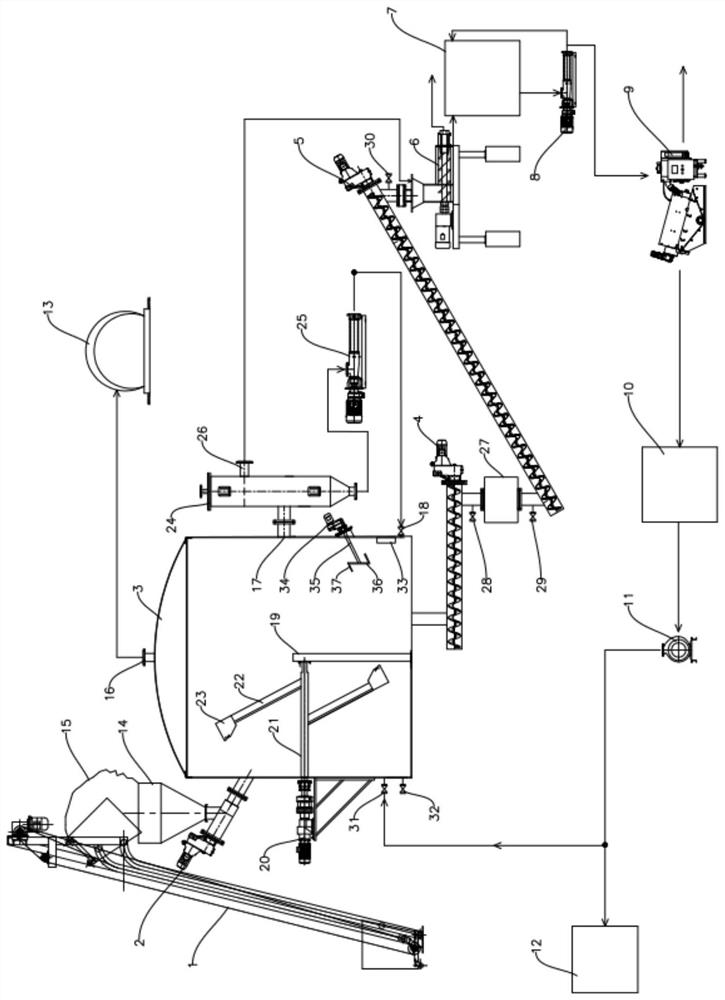

[0059] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0060] refer to figure 1 , a dry-type anaerobic fermentation biogas system for wet garbage, the system sequentially includes a dump bucket elevator 1, a third conveyor 2, an anaerobic generator 3, a first conveyor 4, and a second conveyor from upstream to downstream 2. Conveyor 5, screw press 6, biogas mud temporary storage box 7, biogas mud transportation screw pump 8, screw stacker 9, filtrate temporary storage box 10, centrifugal pump 11 and sewage treatment tank 12, the system also includes biogas storage Cabinet 13.

[0061] The discharge port of the third conveyor 2 is connected to the side wall of the anaerobic generator 3, and the connection position is higher than the effective liquid level height in the anaerobic generator 3, and a feed hopper 14 is arranged at the feed port of the third conveyor 2, The outlet of the tipping bucket elevator 1 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com