Plant transfer printing equipment and application method thereof

A technology for printing and dyeing equipment and plants, applied in the field of plant printing and dyeing equipment, can solve problems such as low work efficiency, different organizational structures, and different shapes, and achieve the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

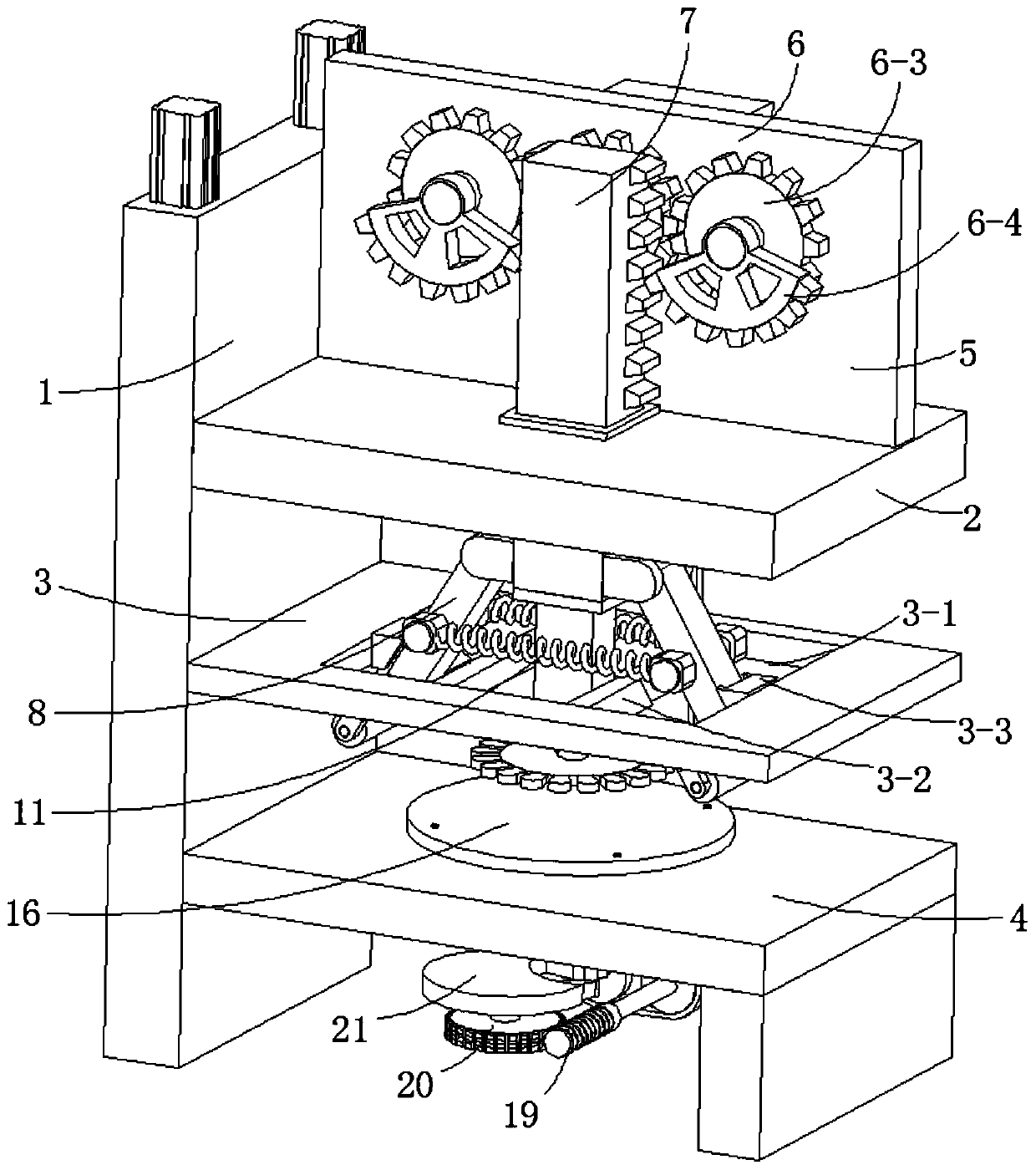

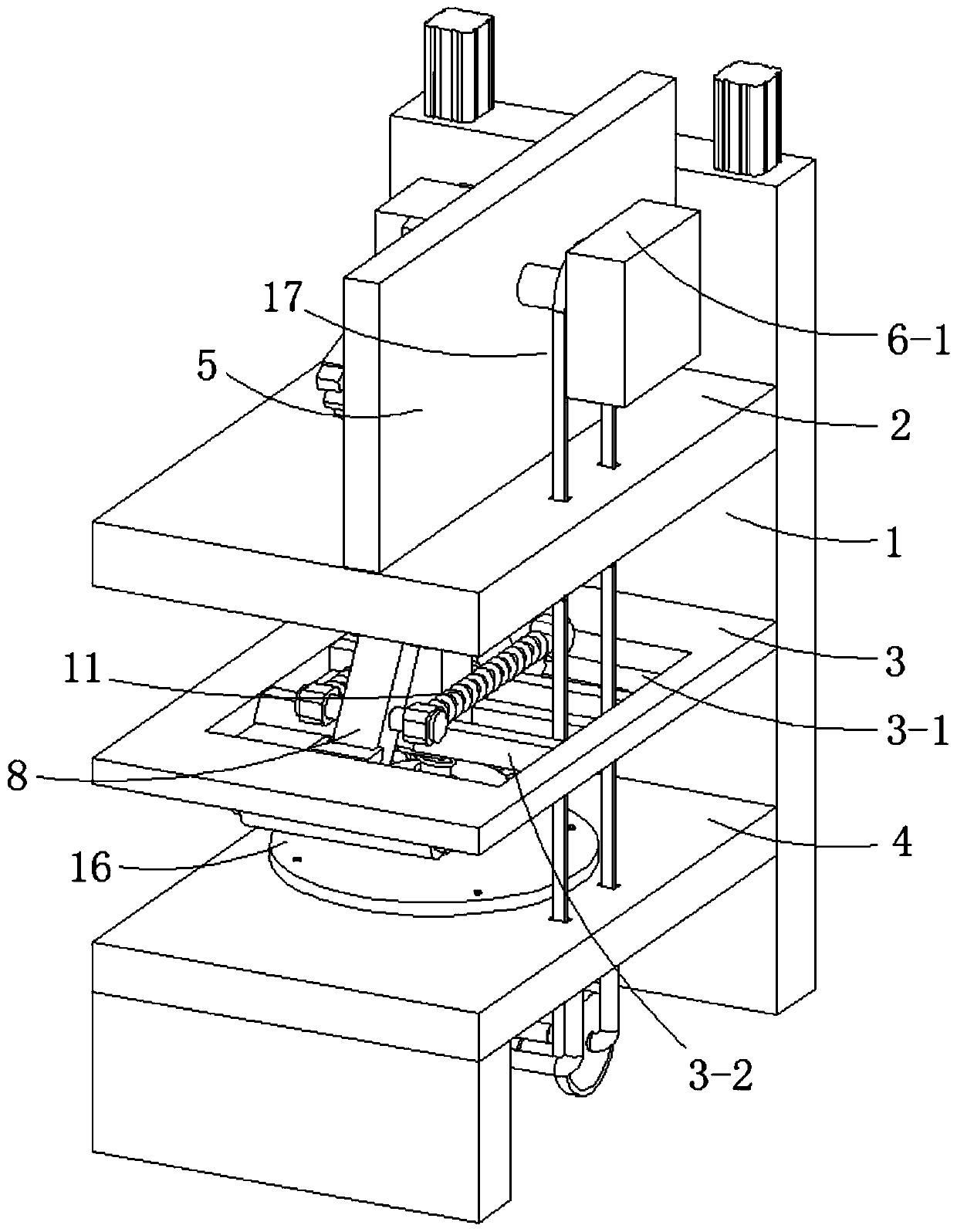

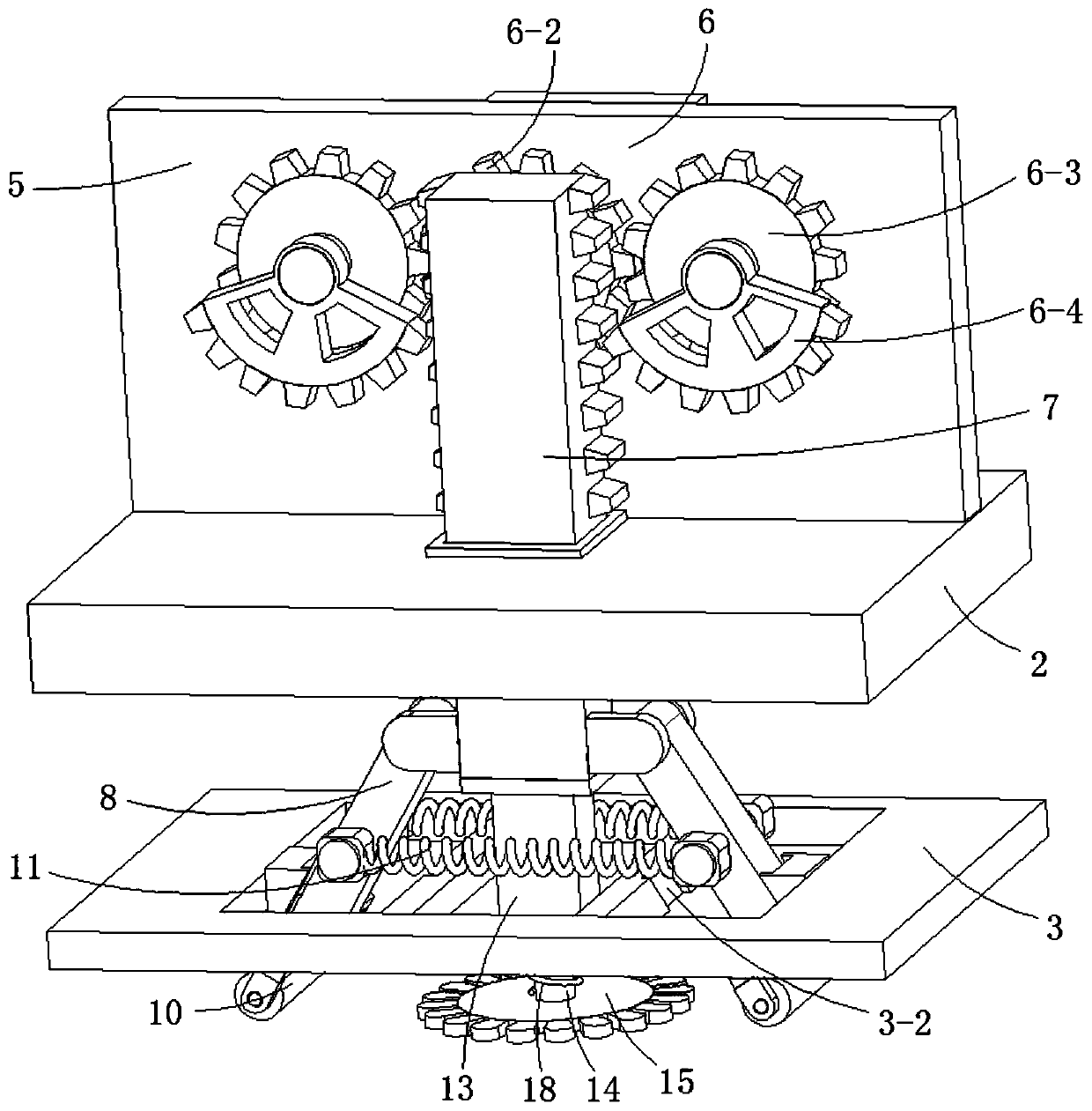

[0037] Embodiment one, with reference to Figure 1-8 , a plant printing and dyeing equipment, comprising a support plate 1, a mounting plate 2, a limiting plate 3, and a workbench 4 are sequentially fixed downward along the vertical direction of the support plate 1; a vertical plate is fixed vertically on the top of the mounting plate 2 5. The side wall of the vertical plate 5 is provided with a reciprocating mechanism 6, and the top of the mounting plate 2 is telescopically connected with a telescopic rack 7, and the output end of the reciprocating mechanism 6 is engaged with the telescopic rack 7, and the outer wall of the bottom end of the telescopic rack 7 A symmetrical transfer rod 8 is rotationally connected, and the bottom end of the transfer rod 8 is fixed with a mounting block 9 through a spring 26. The bottom of the transfer rod 8 is fixed with a fixed column 27, and the mounting block 9 is slidably arranged on the fixed column 27. Above, one end of the spring 26 is ...

Embodiment 2

[0052] Embodiment 2: The setting mode of driving dial 21, sheave 22, driving lever 23, cylindrical pin 24 and radial groove 25 in the intermittent motion mechanism in the present invention is not limited to the mode of the external connection type of the above-mentioned embodiment one, but also can be set as Figure 7 The form shown, that is, adopts the internal connection type, the driving dial 21 is arranged on the inner side of the sheave 22, and the driving dial 21 intermittently moves the sheave 22 through the cylindrical pin 24 on it when rotating, and the groove The wheel 22 further drives the turntable 16 to rotate intermittently, so that the plants are intermittently beaten by the beating disc 15, so that the plant pigments can be evenly printed and dyed on the surface of the plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com