Quick positioning and connecting structure for steel plate shear walls in fabricated building and method

A steel plate shear wall and connecting structure technology, which is applied to building components, building structures, buildings, etc., can solve the problems of poor stability, poor fixing effect, troublesome fixing and understanding, etc., and achieves easy assembly, high utilization rate, The effect of reducing construction cost and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

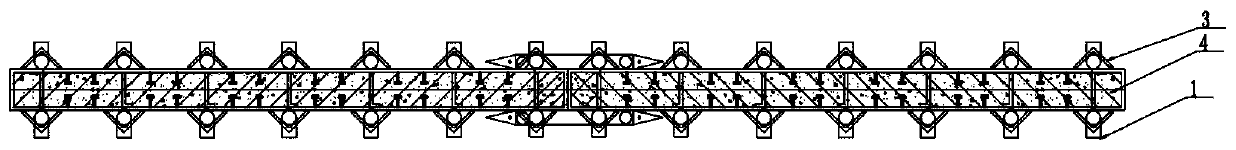

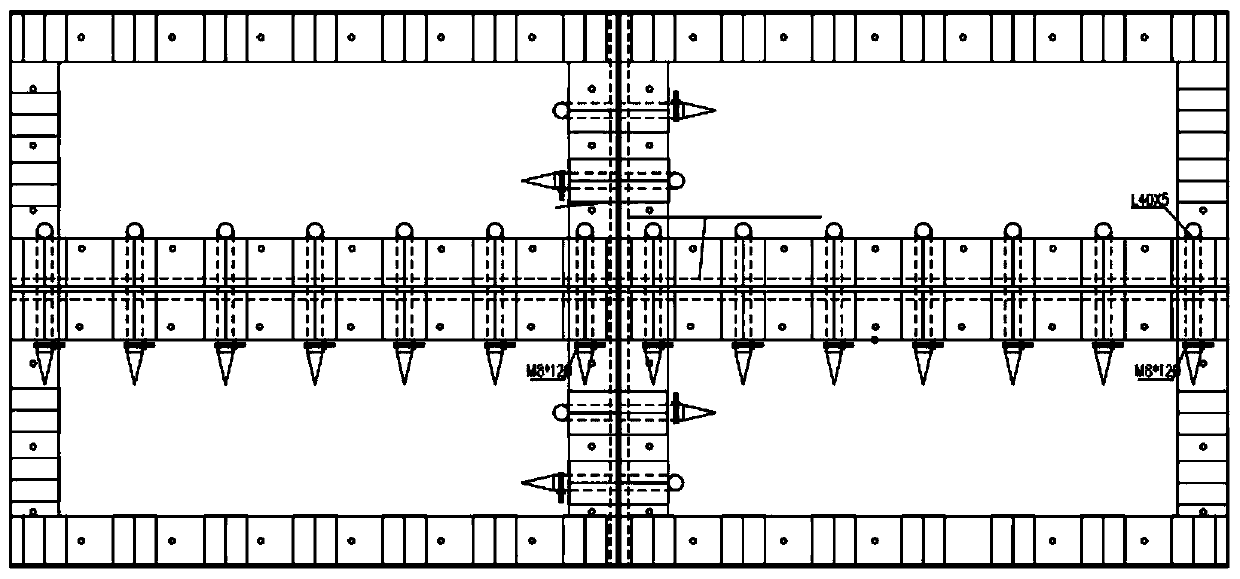

[0024] see Figure 1~2 , in an embodiment of the present invention, a steel plate shear wall rapid positioning connection structure in a prefabricated building includes a positioning pin 1, an angle steel 3 and a shear wall 4, the shear wall 4 is a steel plate lightweight sandwich concrete shear wall, four Each shear wall 4 represents the relationship between up, down, left, and right. There is an inner lining at the junction of every two shear walls 4 to ensure that the joints of the steel plate shear walls 4 achieve penetration welding. For the convenience of assembly, there are A number of angle steels 3 are provided with a number of angle steels 3, the inner lining 2 is in the shape of a "ten", the angle steels 3 are in the shape of an isosceles triangle, and the angle steels 3 are fixedly connected to the shear wall 4 through a positioning pin 1, and the positioning pin 1 is Turnaround positioning deadbolt.

[0025] Preferably, the model of the angle steel 3 is L40*5, an...

Embodiment 2

[0029] A fast positioning connection method between steel plate shears in a prefabricated building, the steps are as follows:

[0030] S1. Use hoisting equipment to hoist the shear wall 4 in place, and then manually move the shear wall 4 up and down to ensure left and right alignment;

[0031] S2. Use the positioning pin 1 for positioning and fixing. Since the end of the positioning pin 1 is tapered, it can be easily positioned and fixed even if there is a slight deviation up and down. After all the positioning and fixing are completed, install and lock the end of each positioning pin Bolt; weld the connecting angle steel 3 spacing 200-250mm one by one on a strip connecting steel plate, and the strip connecting steel plate welded with the angle steel 3 configured on both sides of the shear wall 4 and the corresponding position spacing on the shear wall 4 are 500- A hole with a diameter of M16 is opened along the weld seam and the direction of the steel strips at a distance of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com