Sanitary napkin processing system and sanitary napkin processing method

A processing system and technology for sanitary napkins, which are applied in the field of sanitary napkin production, and can solve the problems of inability to detect the quality of sanitary napkins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

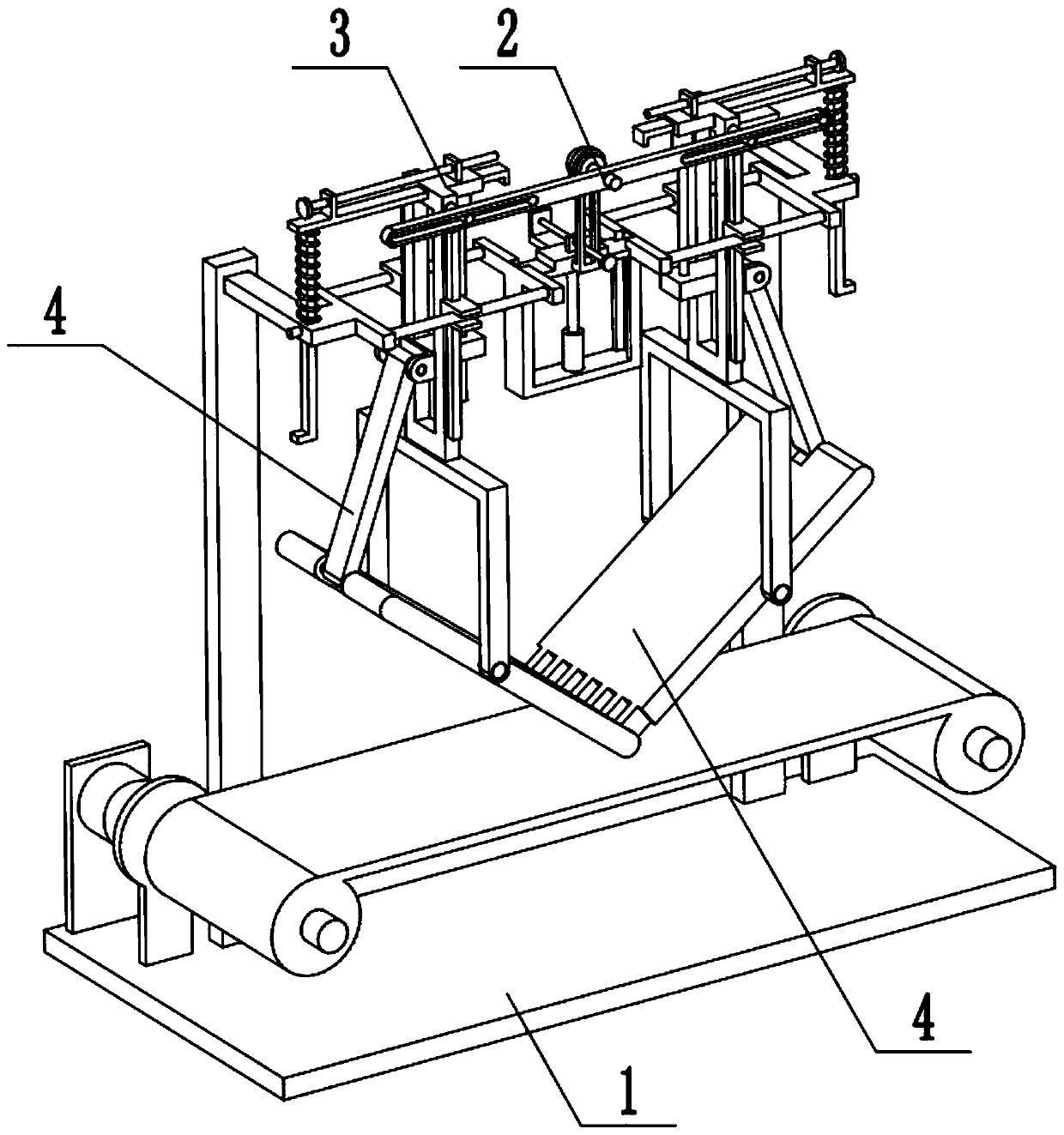

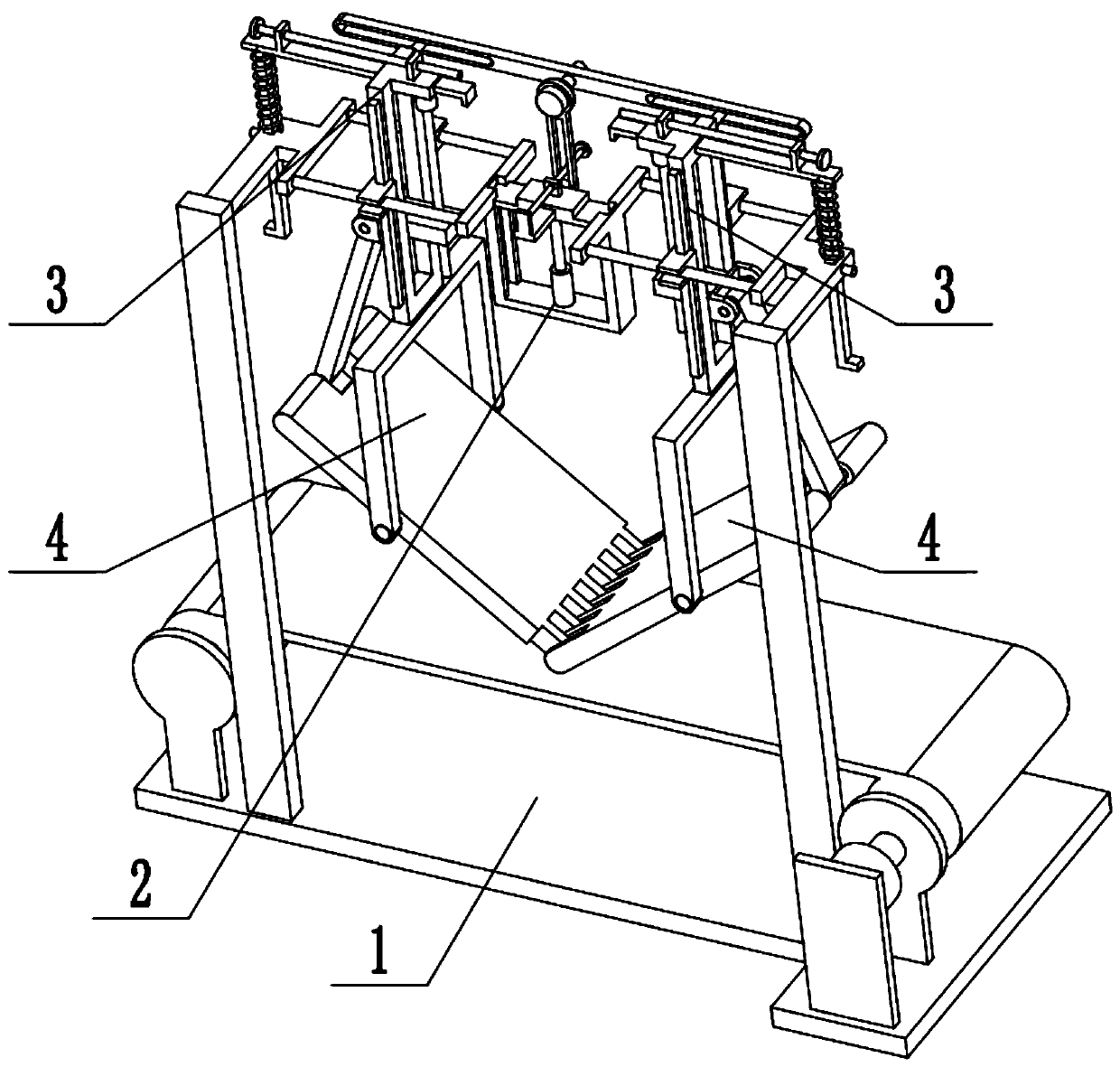

[0033] Combine below Figure 1-7 In this embodiment, the sanitary napkin processing system includes a support assembly 1, a detection drive mechanism 2, a position adjustment mechanism 3 and a detection plate assembly 4. The detection drive mechanism 2 is fixedly connected to the support assembly 1, and the position adjustment mechanism 3 is movable. Fittingly connected to the bracket assembly 1, the detection drive mechanism 2 is flexibly connected to the position adjustment mechanism 3, the detection drive mechanism 2 changes the vertical height of the position adjustment mechanism 3 or drives the position adjustment mechanism 3 to reciprocate, and the detection plate assembly 4 is set at the position Adjusting the lower end of the mechanism 3, the position adjusting mechanism 3 changes the position of the detection board assembly 4 in the horizontal direction. When in use, put the roll of sanitary napkin to be tested on the right sleeve rod 1-3, pull out the end of the sani...

specific Embodiment approach 2

[0035] Combine below Figure 1-7 To illustrate this embodiment, the position adjustment mechanism 3 and the detection board assembly 4 are both provided with two, and the two position adjustment mechanisms 3 are symmetrically arranged at both ends of the bracket assembly 1, and the two ends of the detection drive mechanism 2 and the position adjustment mechanism 3 The ends are movably connected, and the two detection board assemblies 4 are symmetrically arranged on the two position adjustment mechanisms 3, and the lower ends of the two detection board assemblies 4 are cross-fitted and connected. Adjust the vertical height of the two test board assemblies 4 through the detection drive mechanism 2, so that the lower ends of the two test board assemblies 4 are pressed against the flattened sanitary napkin, and there is a line between the two test board assemblies 4 and the sanitary napkin. Contact, during the transfer of the sanitary napkin to the sleeve, the sanitary napkin is d...

specific Embodiment approach 3

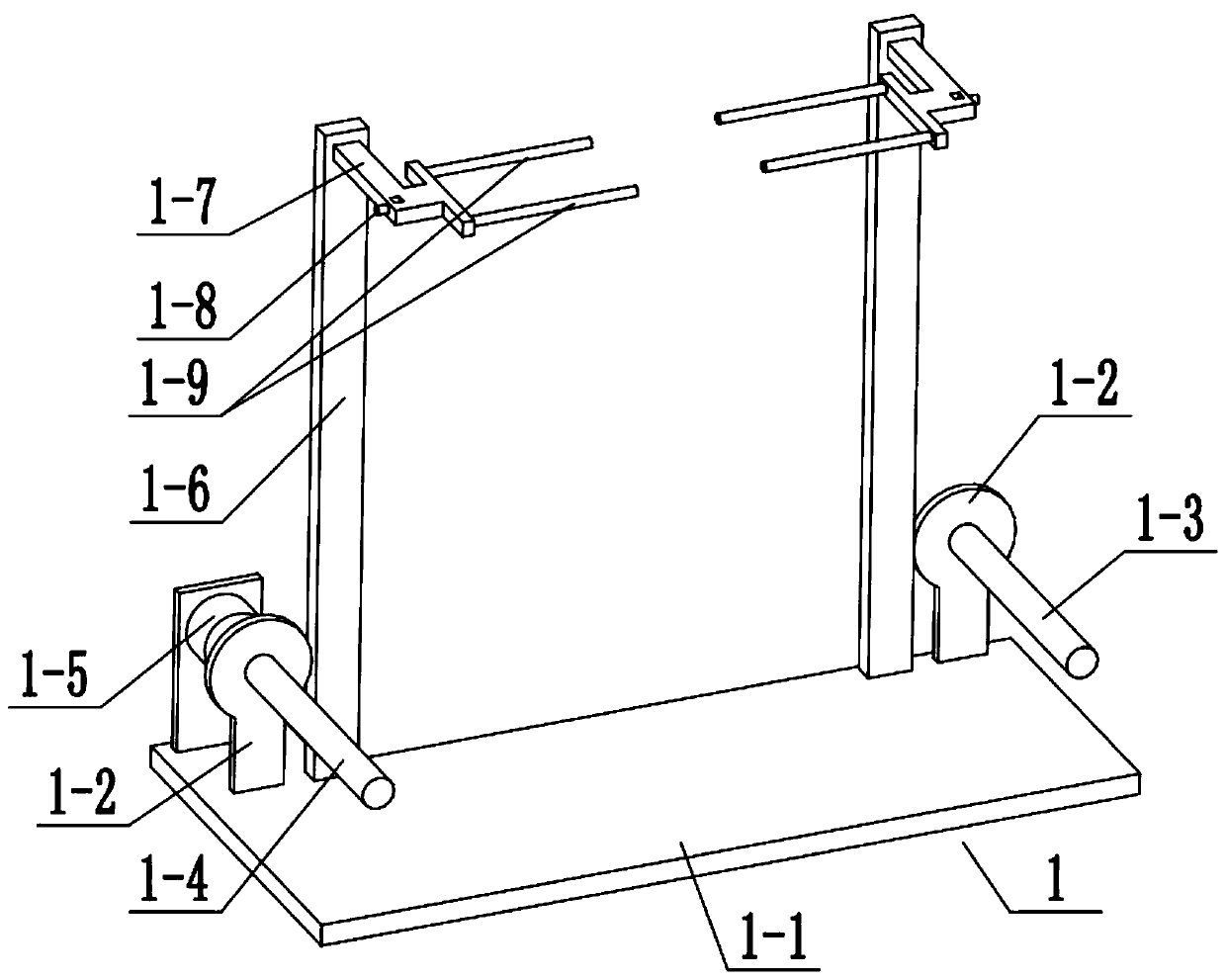

[0040] Combine below Figure 1-7 To illustrate this embodiment, the bracket assembly 1 includes a base plate 1-1, a rear stop frame 1-2, a right sleeve rod 1-3, a left sleeve rod 1-4, a first motor 1-5, and a vertical frame 1-6 , the top frame 1-7, the first locking screw 1-8 and the slide bar 1-9; the two ends of the bottom plate 1-1 are respectively fixedly connected with a rear stop frame 1-2, the right sleeve rod 1-3 and the left sleeve rod 1-4 are rotationally connected to the two rear stop frames 1-2 respectively, the first motor 1-5 is fixedly connected to the bottom plate 1-1 through the motor frame, and the output shaft of the first motor 1-5 is connected to the left side through a coupling. The rear end of the sleeve rod 1-4 is fixedly connected with two vertical frames 1-6 on the bottom plate 1-1, and the two top frames 1-7 are symmetrically arranged on the two vertical frames 1-6, and the two top frames 1-7 The inner ends of the two slide bars 1-9 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com