All-optical BEC preparation method based on three-dimensional Raman sideband cooling

An optical and evaporative cooling technology, applied in the field of precision measurement, can solve the problems of unfavorable application in the field of precision measurement, high requirements for magnetic traps, and long preparation time, and achieve the effects of shortening preparation time, improving preparation efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

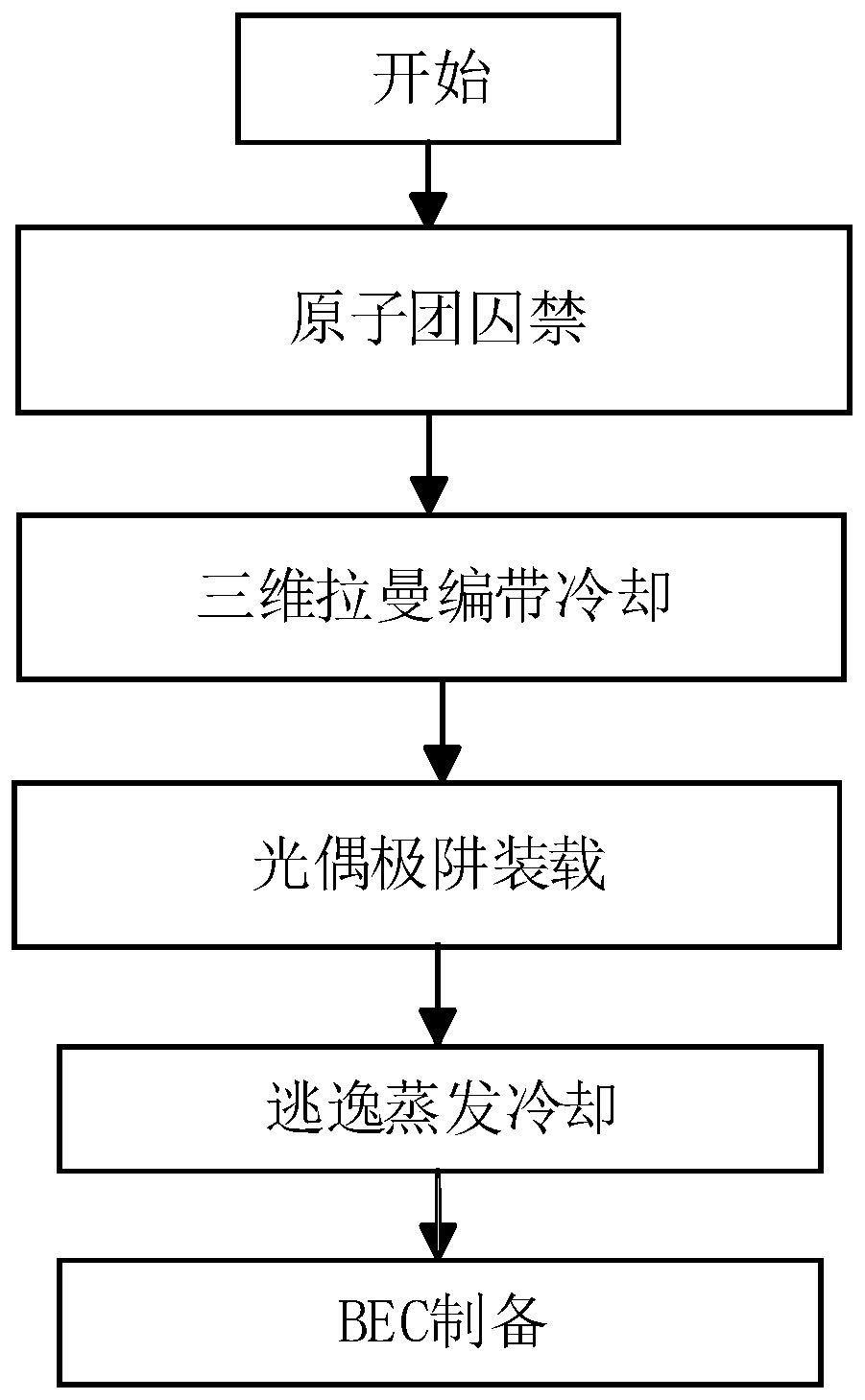

[0035] Such as figure 1 Shown, a kind of all-optical BEC preparation method based on three-dimensional Raman sideband cooling of the present invention, its steps are:

[0036] Step S1: Preparation of cold atomic groups.

[0037] Six beams of cooling light and back-pumping light in three directions of X-Y-Z form a magneto-optical trap, trapping a group of atoms with a number of about 10 9 At this time, the temperature of the atomic group is relatively high, about 200μK.

[0038] Step S2: Polarization gradient cooling.

[0039] Within a certain period of time (such as within 20ms), linearly reduce the power of the cooling light, and at the same time increase the detuning of the cooling light to -100MHz, complete the polarization gradient cooling process, and obtain cold atomic groups with a temperature of about 15μk. At this time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com