Temperature detection method of permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and detection method, which is applied in the direction of motor control, electrical components, control system, etc., can solve the problems of motor speed and torque ripple, poor feasibility of temperature detection, affecting calculation accuracy, etc., to achieve accurate temperature monitoring, High accuracy and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

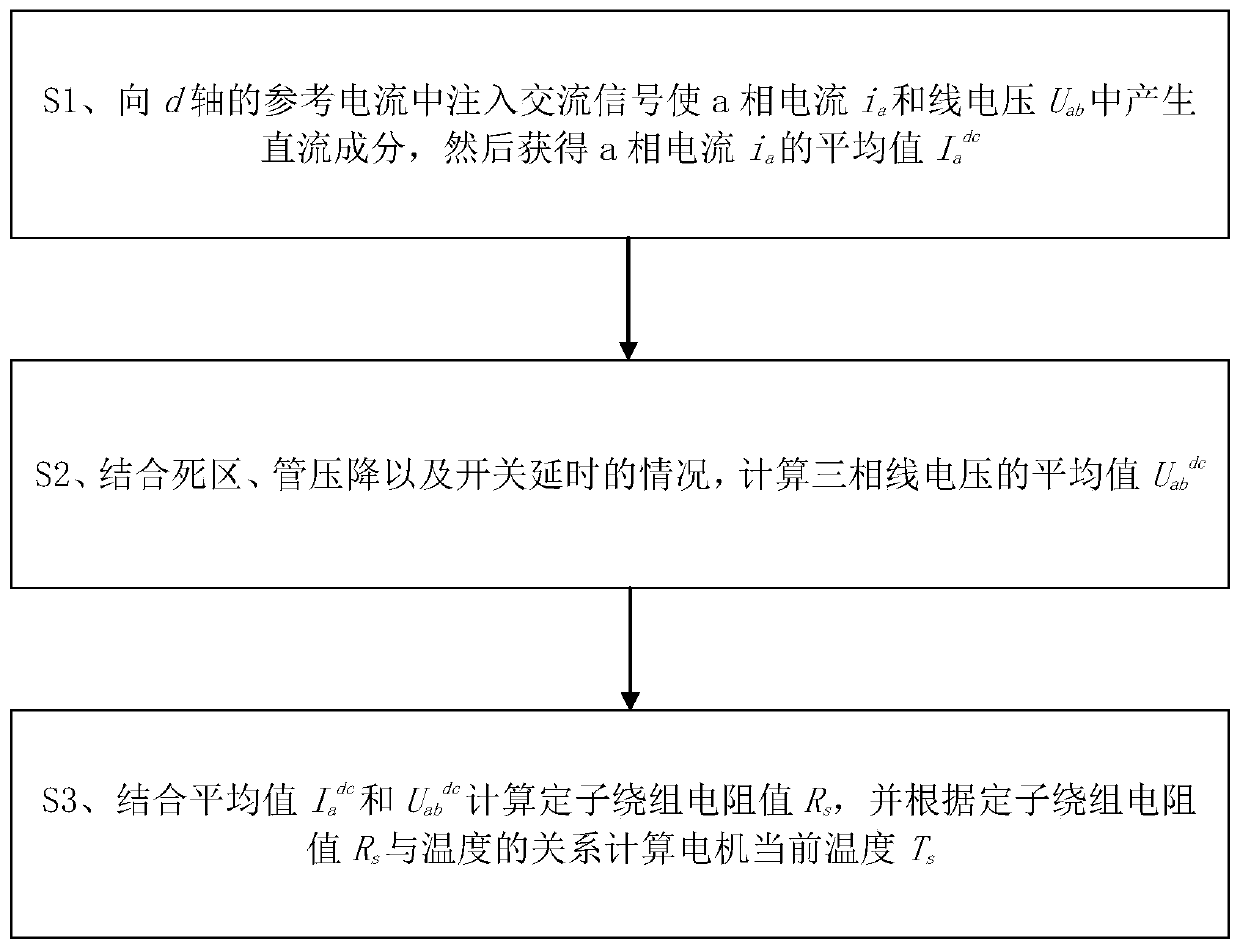

[0023] refer to figure 1 A method for detecting the temperature of a permanent magnet synchronous motor proposed by the present invention includes the following steps.

[0024] S1. Inject an AC signal into the reference current of the d-axis to make the a-phase current i a and line voltage U ab A DC component is generated in the middle, and then the a-phase current i is obtained a the average value of I a dc . During specific implementation, the duty cycle of the PWM signal and the DC bus voltage U dc .

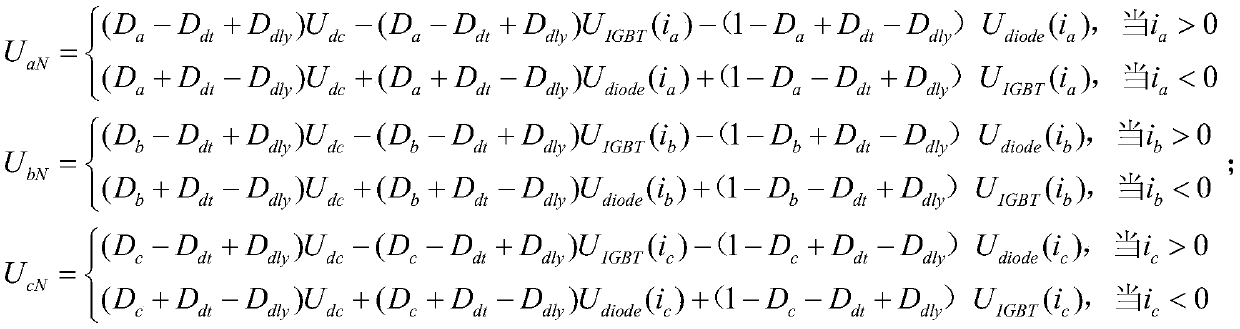

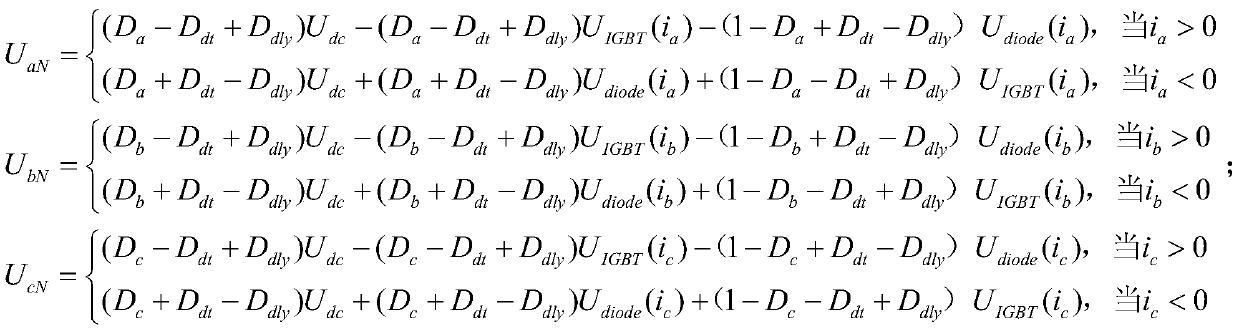

[0025] S2. Calculate the average value U of the three-phase line voltage in combination with the dead zone, tube voltage drop and switch delay ab dc .

[0026] Specifically, in this step, the average value U of the three-phase voltage is calculated by using the duty cycle of the PWM signal and the DC bus voltage in combination with the dead zone, the tube voltage drop and the switching delay. ab dc .

[0027] S3, combined with the average value I a dc and U ab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com