Jig and production method for double-sided reinforced FPC soft board

A production method and technology for flexible boards, applied in the direction of laminated printed circuit boards, circuit bendable/stretchable parts, electrical components, etc., can solve problems such as normal production, equipment failure, affecting printing or patching, etc. , to achieve the effect of being conducive to normal production, balancing the difference in height, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

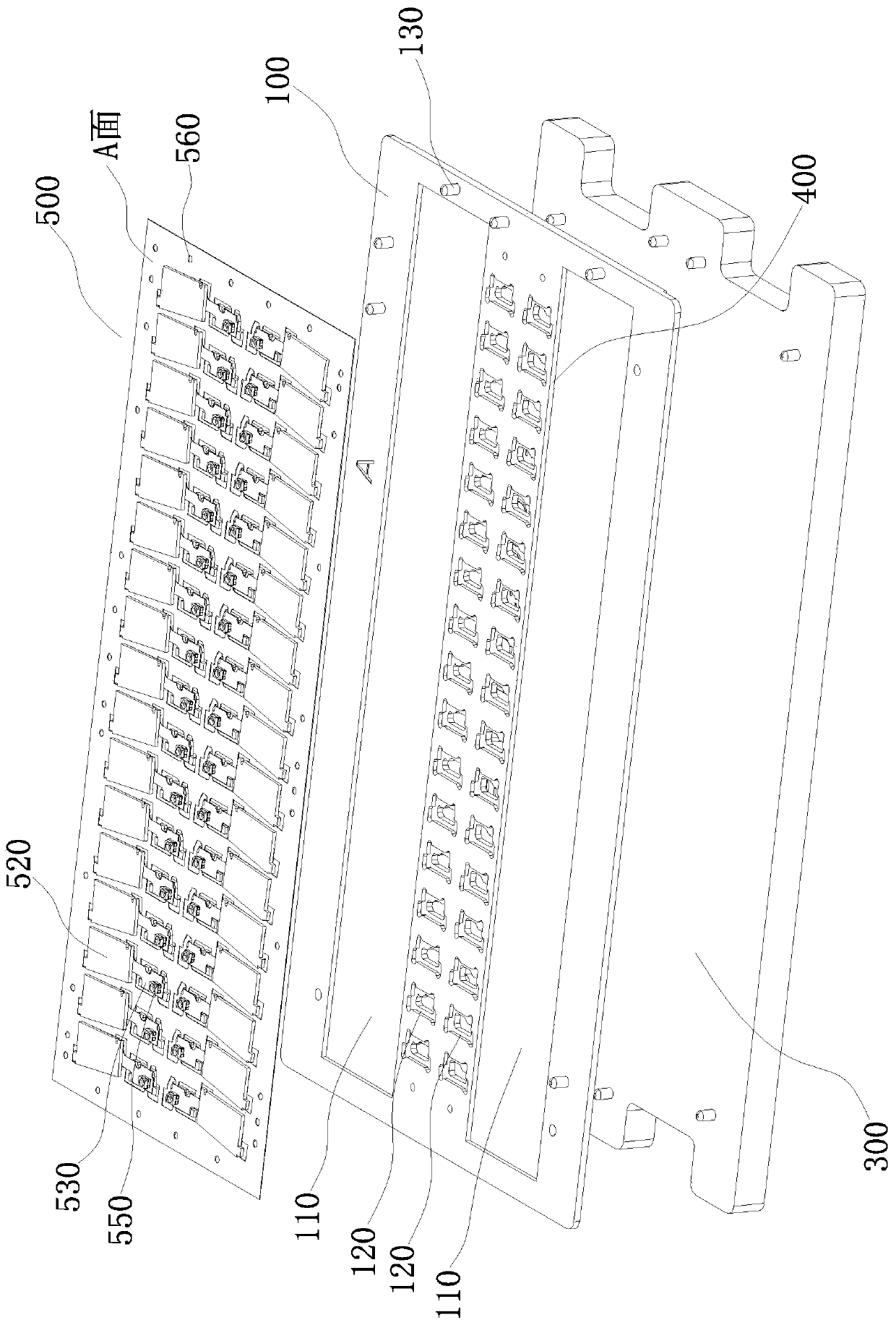

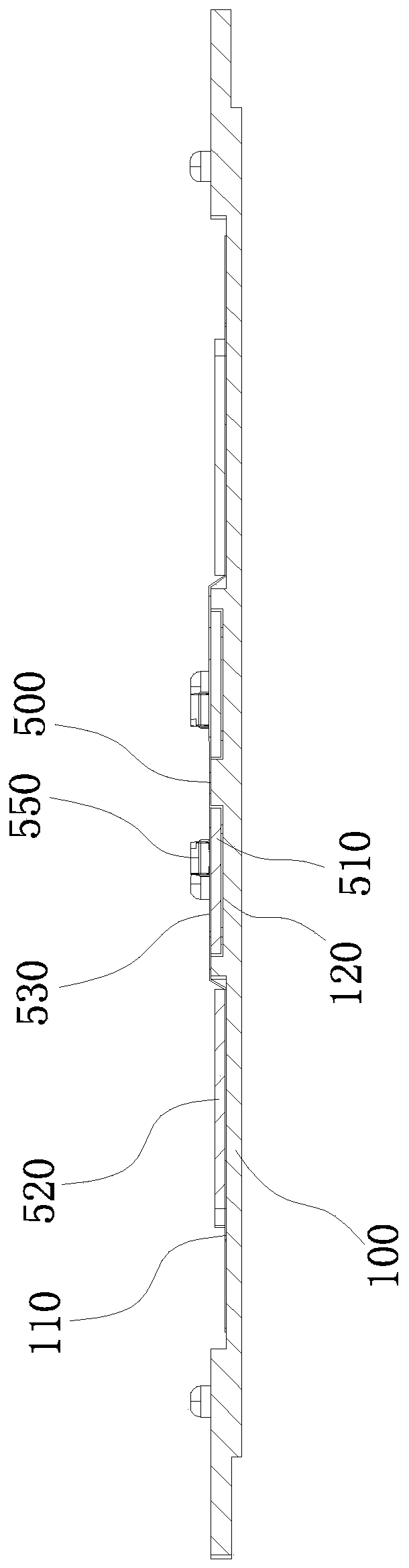

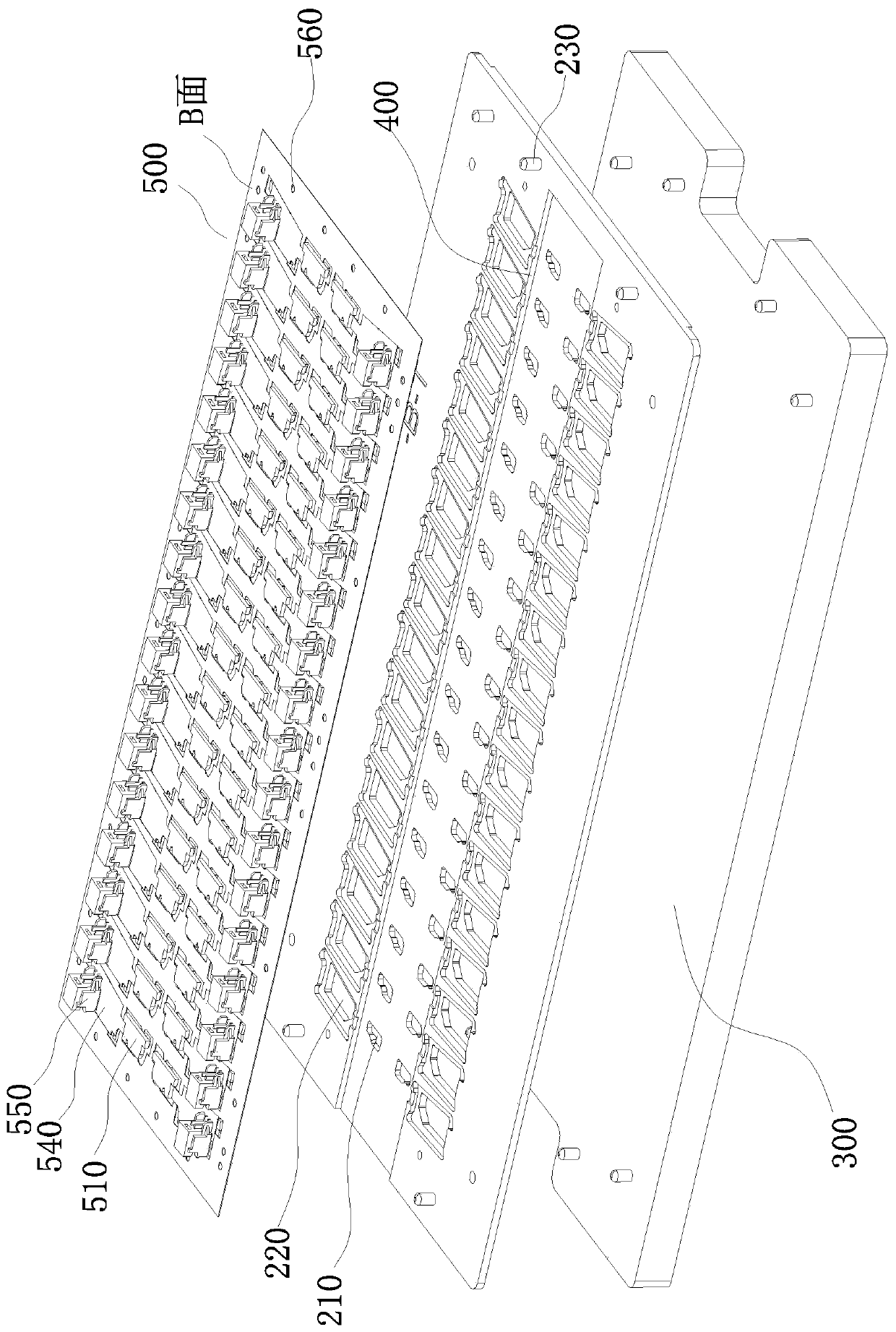

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a double-sided reinforced FPC soft board fixture is used to assist the printing and patching of the FPC soft board 500, wherein the FPC soft board 500 is a flexible circuit board (Flexible Printed Circuit board), flexible circuit board The board is characterized by being thin and short, so it is easy to be hit, folded, and scratched during use; the mechanical strength is small, and it is easy to crack. The purpose of bonding the reinforcing material (stiffener) is to strengthen the mechanical strength of the FPC board and facilitate the insertion of surface-mounted parts or parts.

[0036] The FPC soft board 500 has an A side and a B side, that is, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com