Environment-friendly treatment process for steel mill waste gas emission

A waste gas emission and environmental protection treatment technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and dispersed particle filtration, can solve the problems of the influence of the filter structure on the filtration effect, the low degree of adsorption of impurities in the filter, and the neglect of the use of heat energy of the waste gas, etc., to achieve Avoid the reduction or loss of adsorption capacity, reduce the chance of poor connection sealing, and facilitate installation and disassembly for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

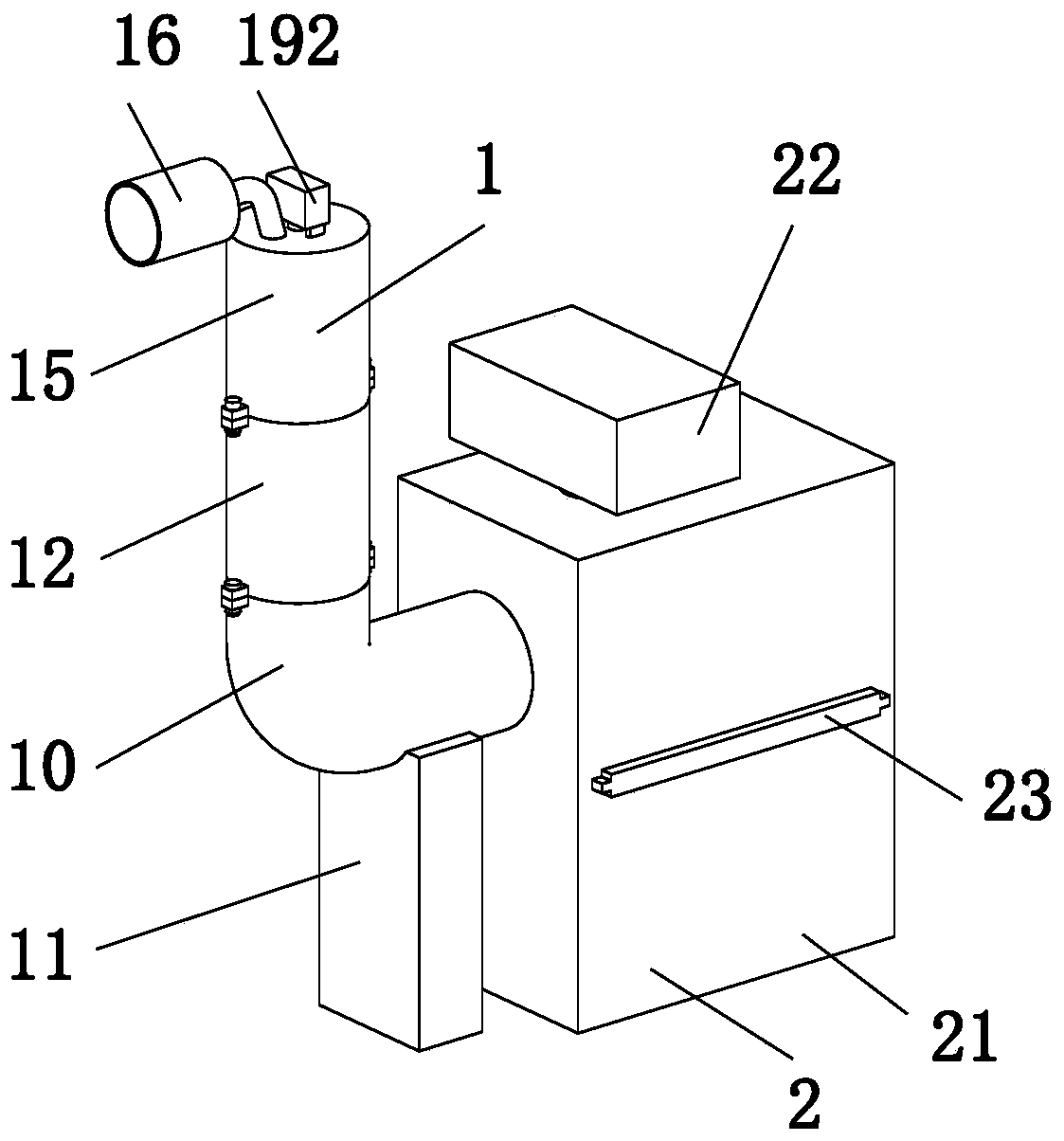

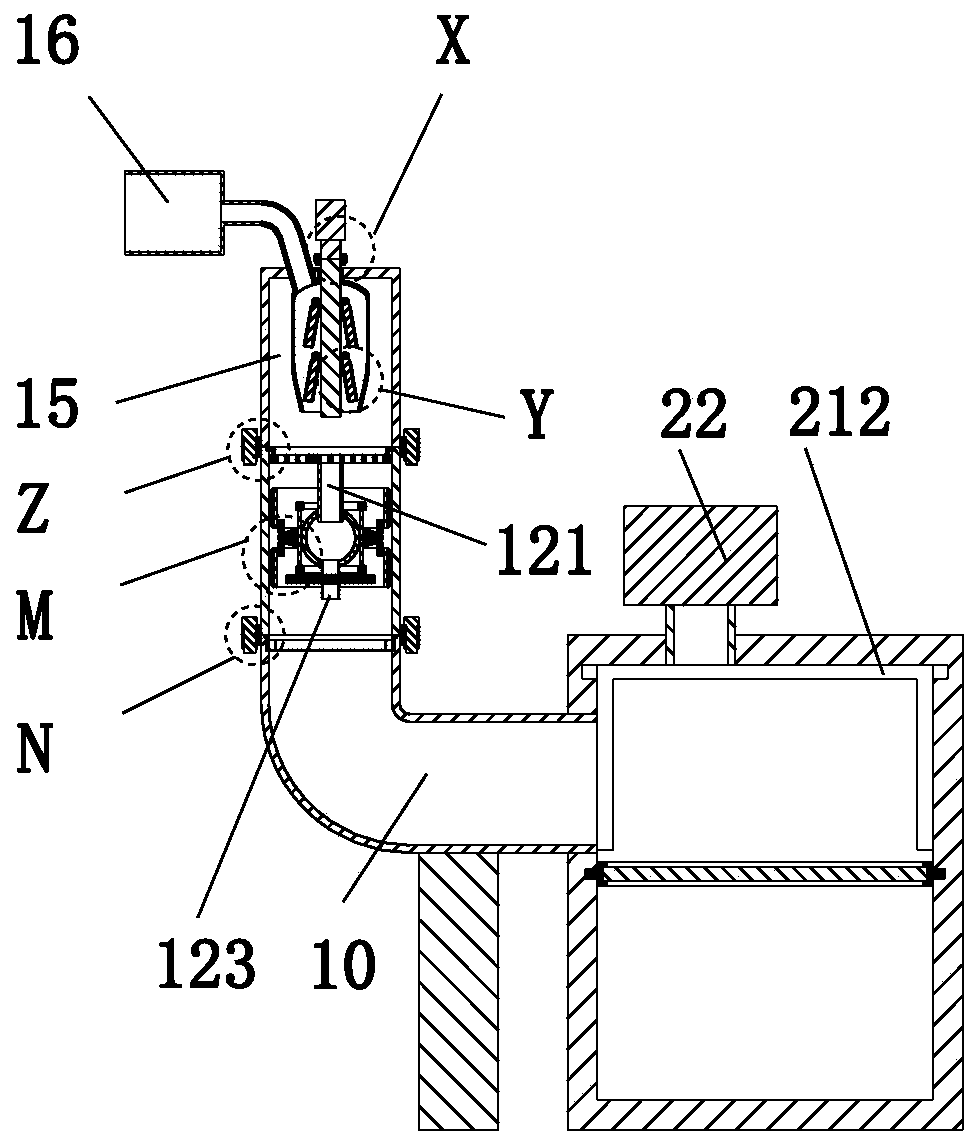

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

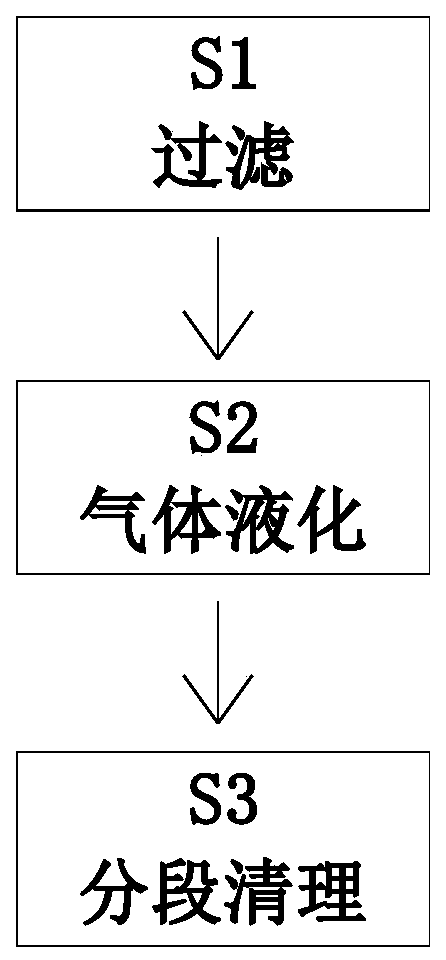

[0040] like Figure 1 to Figure 12 As shown, an environmental protection treatment process for exhaust gas emission in a steelmaking plant uses an environmental protection treatment device for exhaust gas emission in a steelmaking plant. The specific treatment process of the plant waste gas emission environmental protection treatment device for the environmental protection treatment of the steel plant waste gas emission is as follows:

[0041] S1. Filtration: the gas enters the dust collection bag 198 through the intake pipe 16 and continues to flow downward. The dust collection bag 198 can adsorb the impurities in the exhaust gas, and the exhaust gas continues to flow downward through the filter plate 199, which is 199 It can be filtered twice;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com