Steel mill waste gas emission environment protection treatment system

A waste gas emission and environmental protection treatment technology, which is applied in the direction of cleaning hollow objects, combined devices, cleaning methods and appliances, etc., can solve the problems of the influence of the filtering structure on the filtering effect, the low degree of impurity filtration and adsorption, ignoring the use of heat energy of the waste gas, etc., so as to avoid Decrease or loss of adsorption capacity, reduce the effect of poor connection sealing, and facilitate installation and disassembly for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways predetermined and covered by the claims.

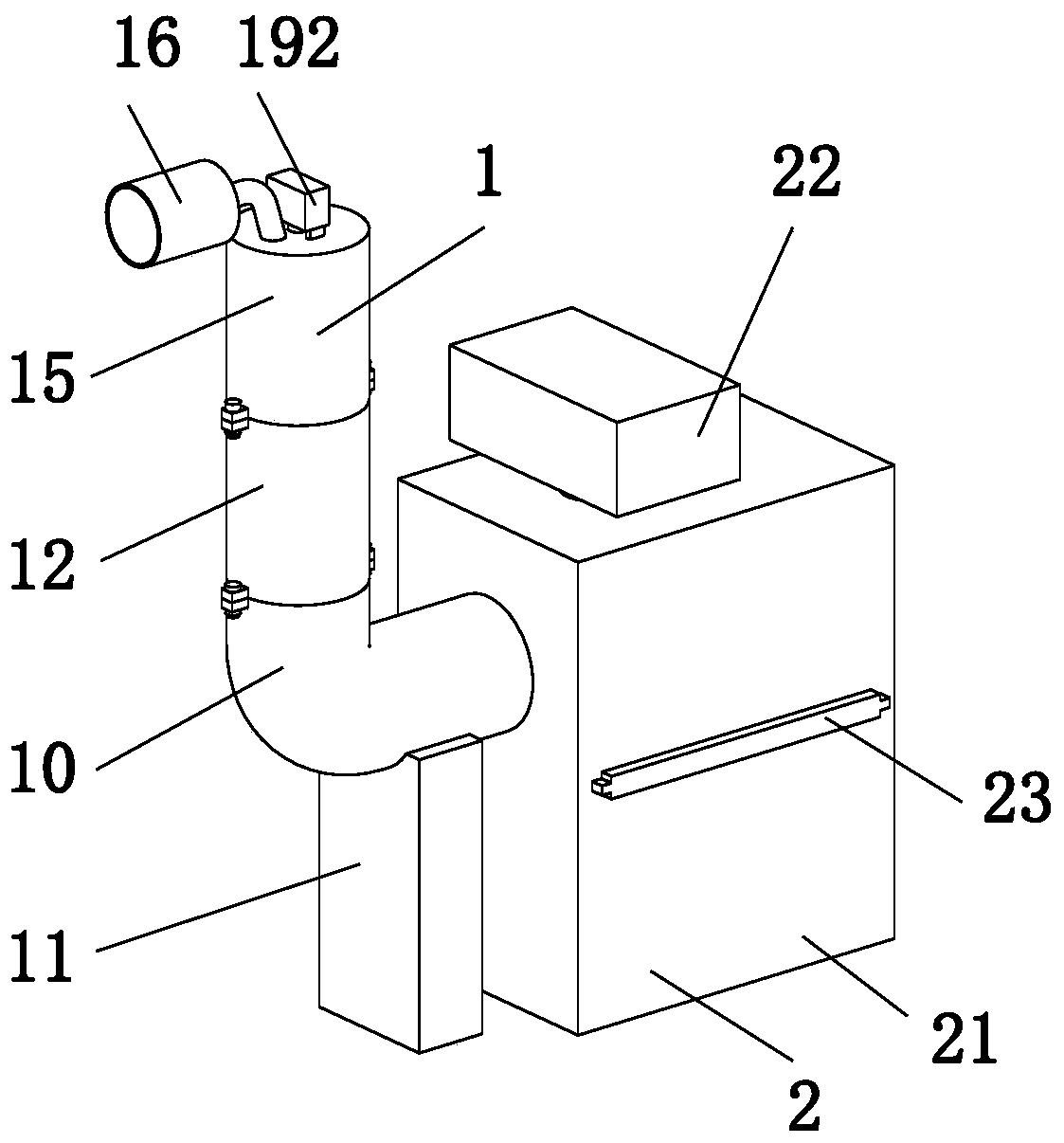

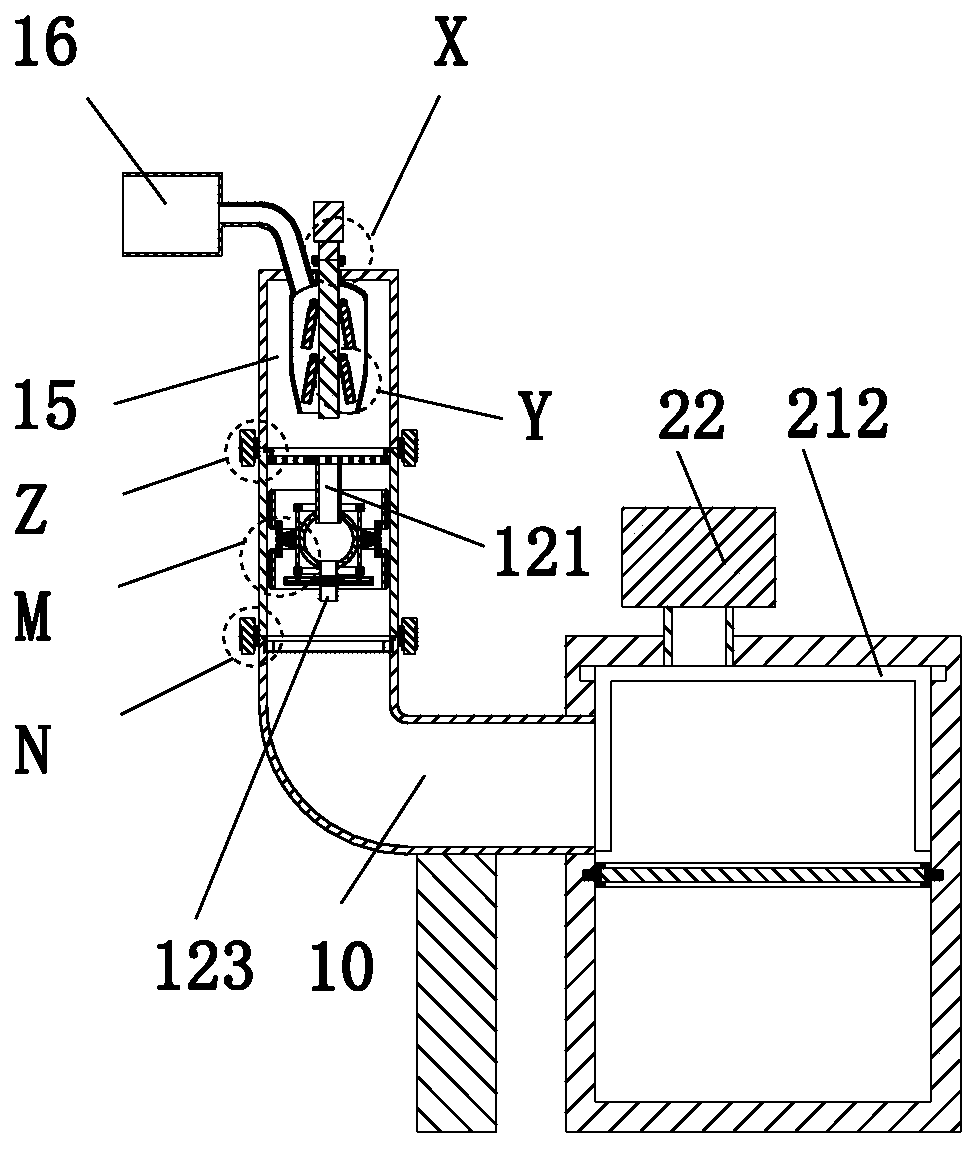

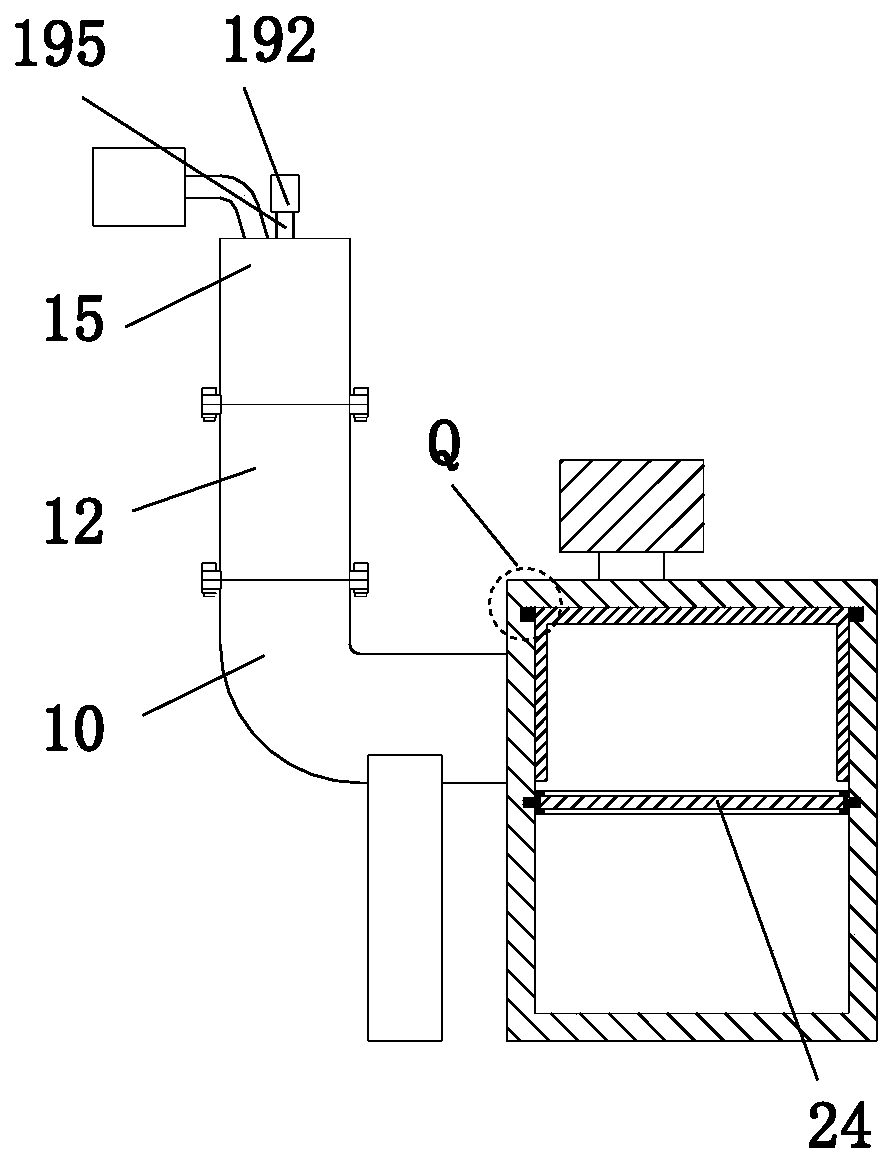

[0035] Such as Figure 1 to Figure 11 As shown, an environmental protection treatment system for waste gas emissions from a steelmaking plant includes a filtering mechanism 1 and a liquefaction mechanism 2. The right end of the filtering mechanism 1 is connected with a liquefaction mechanism 2, and the lower end of the liquefaction mechanism 2 is installed on an existing work ground.

[0036] The filter mechanism 1 includes an L-shaped pipe 10, a support seat 11, a No. 1 pipe 12, a No. 1 bump 13, a No. 1 bolt 14, a No. 2 pipe 15, an intake pipe 16, a No. 2 bump 17, and a No. 2 bolt 18 and the filter cleaning group 19, the right end of the L-shaped tube 10 and the left end of the liquefaction mechanism 2 are connected by threaded fitting, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com