Reverse laser forming method for single-segment arc surface of metal sheet

A technology of laser forming and sheet metal, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problem of poor smoothness effect of arc surface, does not derive the mathematical relationship of the curvature radius of arc surface, and does not consider arc problems such as the effect of surface smoothness, to achieve the effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

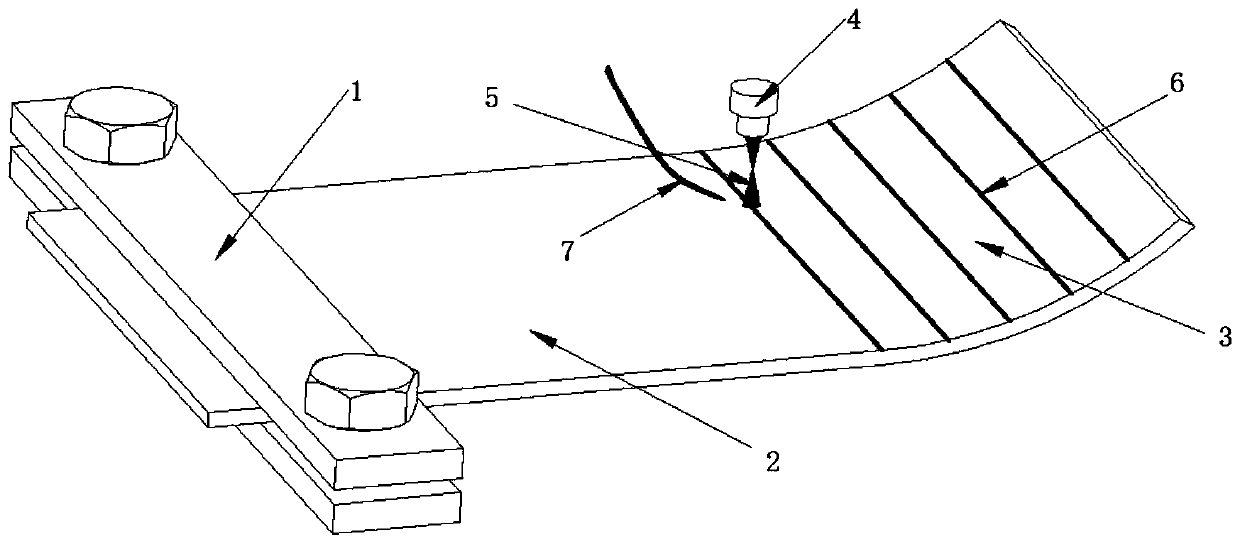

[0024] Example 1: A single-segment circular arc surface sample is formed by laser bending of a metal sheet.

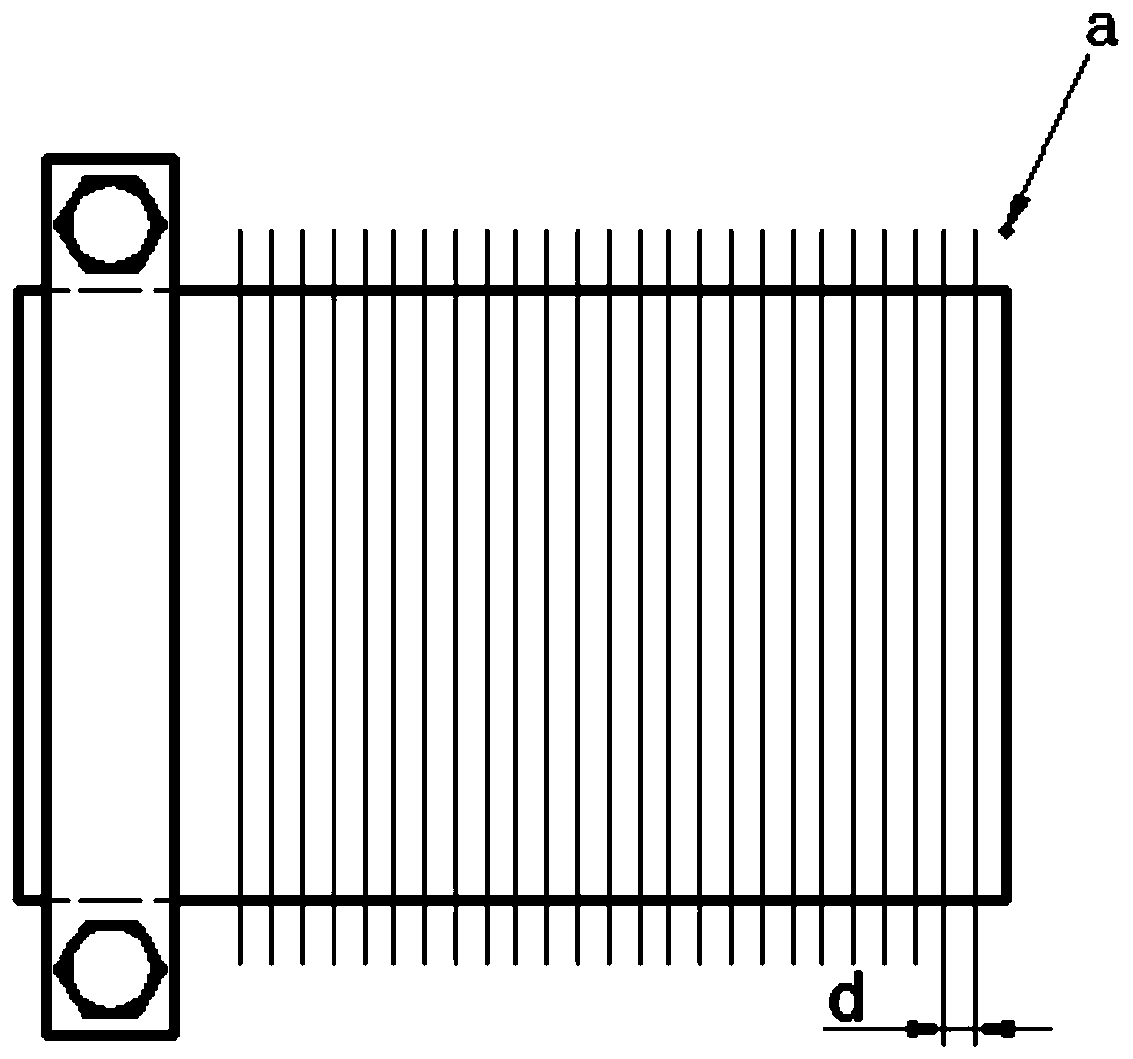

[0025] (1) Use a shearing machine to cut a metal composite plate with a thickness of 1mm into a rectangular sample with a width of 50mm and a length of 77.8mm. The radius of curvature of the arc surface is R=60mm, the central angle θ=60°, and the arc length corresponds to The length of the plate is L=62.8mm, and the width of the flat plate for extra clamping is 15mm;

[0026] (2) When the laser power is 140W, the scanning speed is 400mm / min, the defocus amount is 10mm, the laser frequency is 40Hz, and the pulse width is 2ms, the bending angle α of a single laser scan is obtained. 0 =2.1°, which is set as the reference angle; the defocus amount is fixed throughout the bending process, and the corresponding spot diameter D = 1.8mm when the defocus amount is 10mm.

[0027] (3) The central angle θ=60°>5° corresponding to the arc surface, and the bending angle range of the...

Embodiment 2

[0030] Example 2: A sample of a single-period three-segment arc surface of a heat shield formed by laser bending of a metal plate.

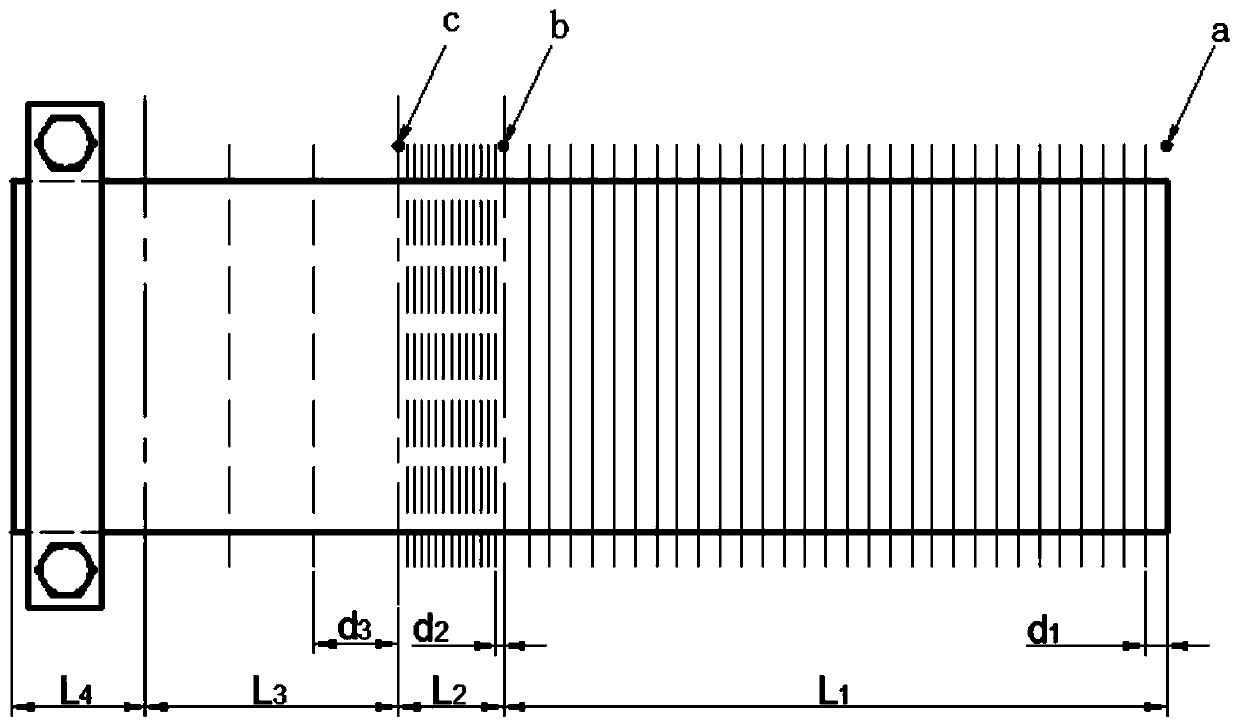

[0031] (1) Use a shearing machine to cut the metal composite plate with a thickness of 1mm into a rectangular sample with a width of 50mm and a length of 88mm, where the radius is R 1 = 38mm arc surface 1 corresponds to the plate length L 1 =47.4mm, radius R 2 The arc surface 2 of =11mm corresponds to the plate length L 2 =7.5mm, the radius is R 3 = 536.1mm arc surface 3 corresponds to the plate length L 3 =18.1mm, the width L of the flat plate for excess clamping 4 = 15mm;

[0032] (2) When the laser power is 140W, the scanning speed is 400mm / min, the defocus is 10mm, the laser frequency is 40Hz, and the pulse width is 2ms, the single-track single laser scanning bending angle α is obtained. 0 , a 0 =2.1°; the defocus amount is constant throughout the bending process, and the corresponding spot diameter D=1.8mm when the defocus amount is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com