A Preparation Technology of Optical Ring Die with Restriction of Hole Retraction

A preparation process and ring die technology, which is applied in the field of hole shrinkage-restraining light-type ring die preparation process, can solve the problems of roundness damage, poor ring die use effect, and increased defective rate, so as to ensure the shaping effect , strong self-bearing capacity, and the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation process of an optical ring die with suppressed hole retraction, comprising the following steps:

[0053] S1. First, select the appropriate ring die semi-finished product according to the required ring die specifications;

[0054] S2. Drill the semi-finished product of the ring die through an eight-station CNC deep hole gun drill to obtain a die hole;

[0055] S3. According to the required aperture requirements, use a reaming machine to ream the die hole to obtain a ring die with a die hole;

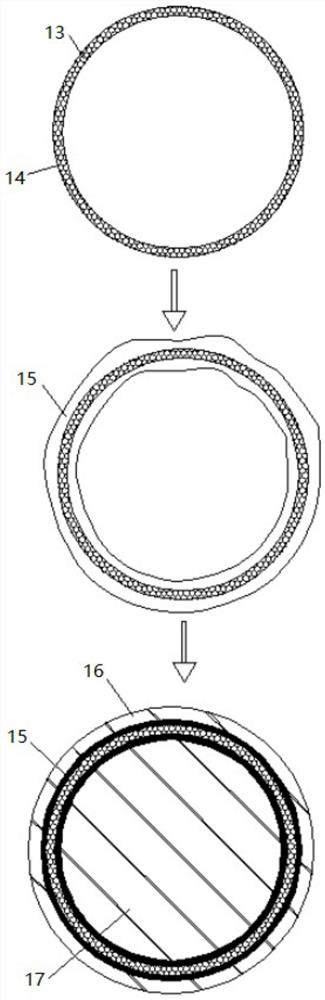

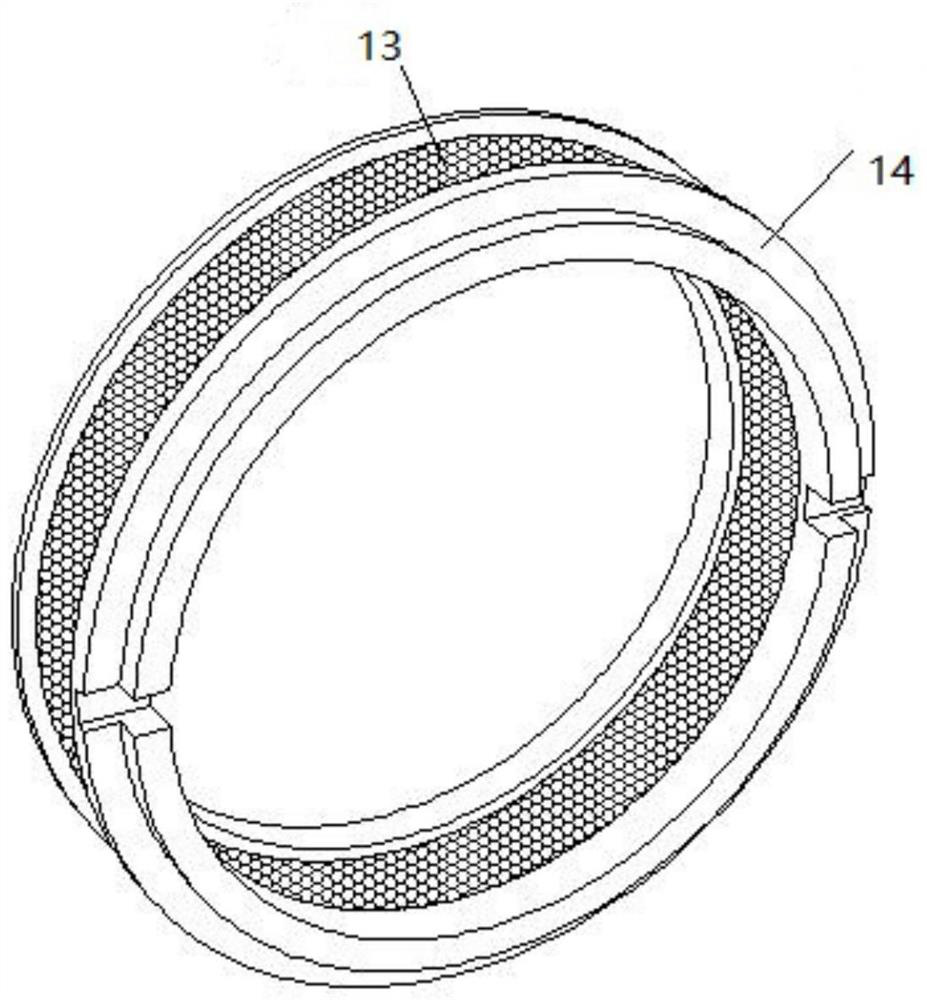

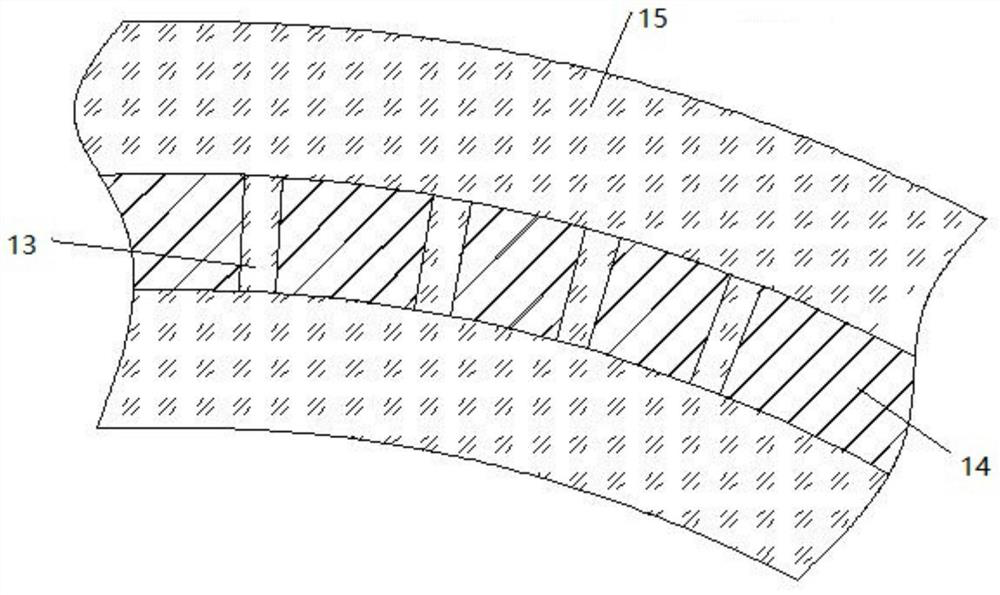

[0056] S4. Remove the debris on the ring die after drilling and reaming, see figure 1 , and gently extrude the embedded shrink-controlled mass from the inside of the ring die into the die hole until the embedded shrink-controlled mass passes through the die hole on the ring die and extends to the outside of the ring die, and is completely wrapped inside and outside the ring die ;

[0057] S5. Use the inner pneumatic shaping column to shape the part of the embedded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com