A feeding device, a polishing device and a finishing machine for a finishing machine

A technology of feeding device and fine turning, applied in the field of micro-motor equipment manufacturing, can solve the problems of increasing manpower input, uncoordinated movements, affecting rhythm requirements, etc., and achieves the effect of saving space and cost, improving work efficiency, and meeting production requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

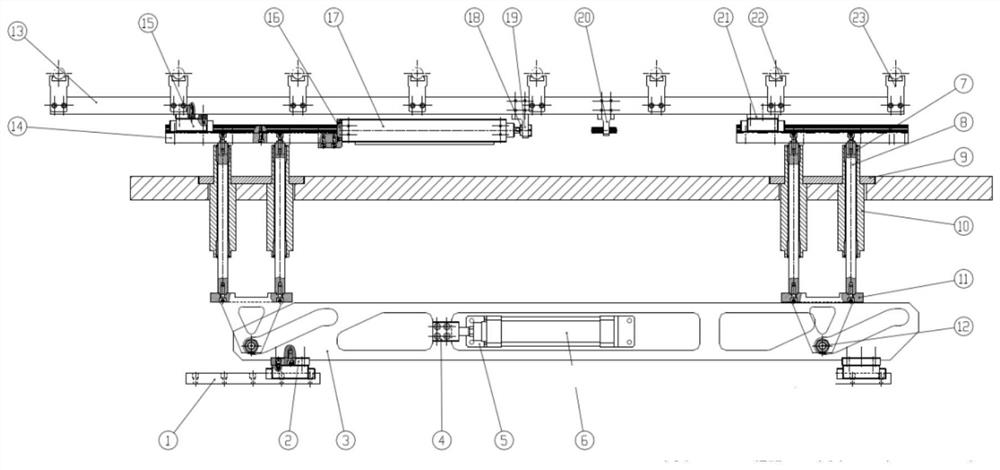

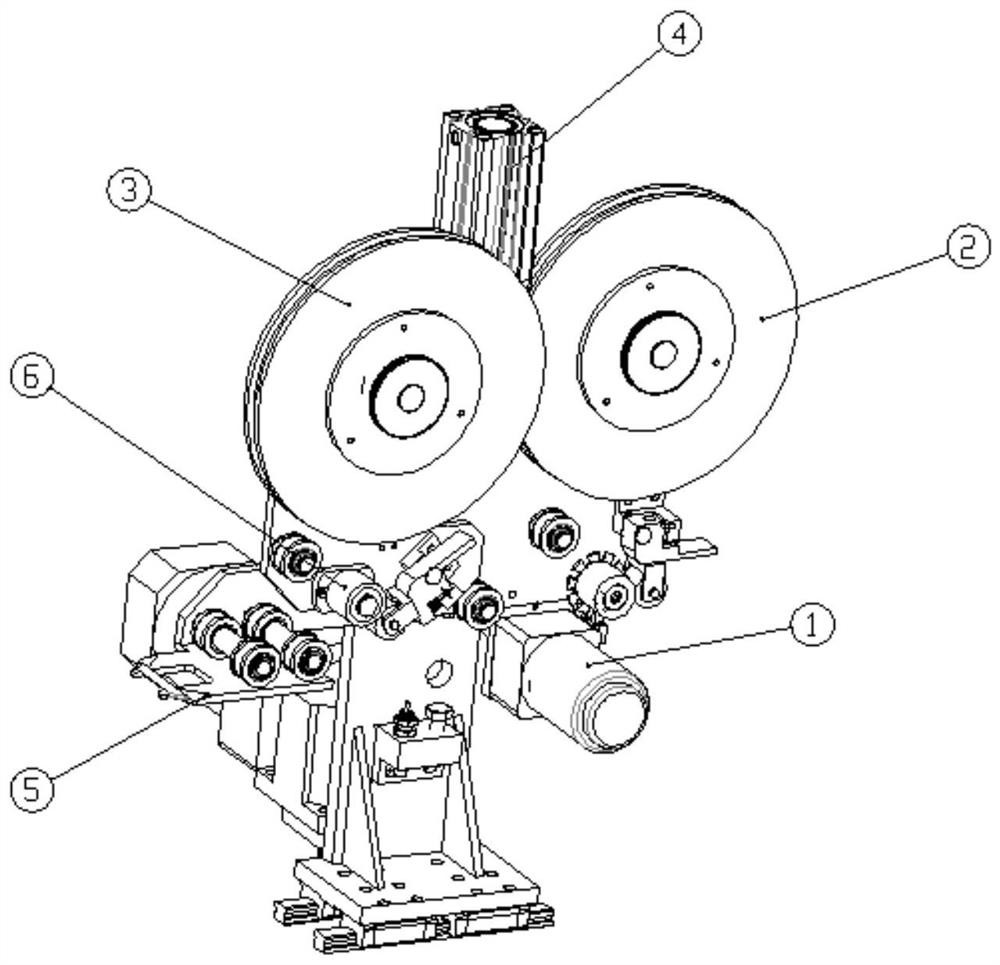

[0035] Such as Figure 11 As shown, a finishing machine includes a turning pressing device A, a brush pressing device C, a brushing machine E, a knife table F, and also includes a polishing device B for the rotor commutator, a feeding device D, turning The belt pressing device A, the brush belt pressing device C and the polishing device B are located above the feeding device D.

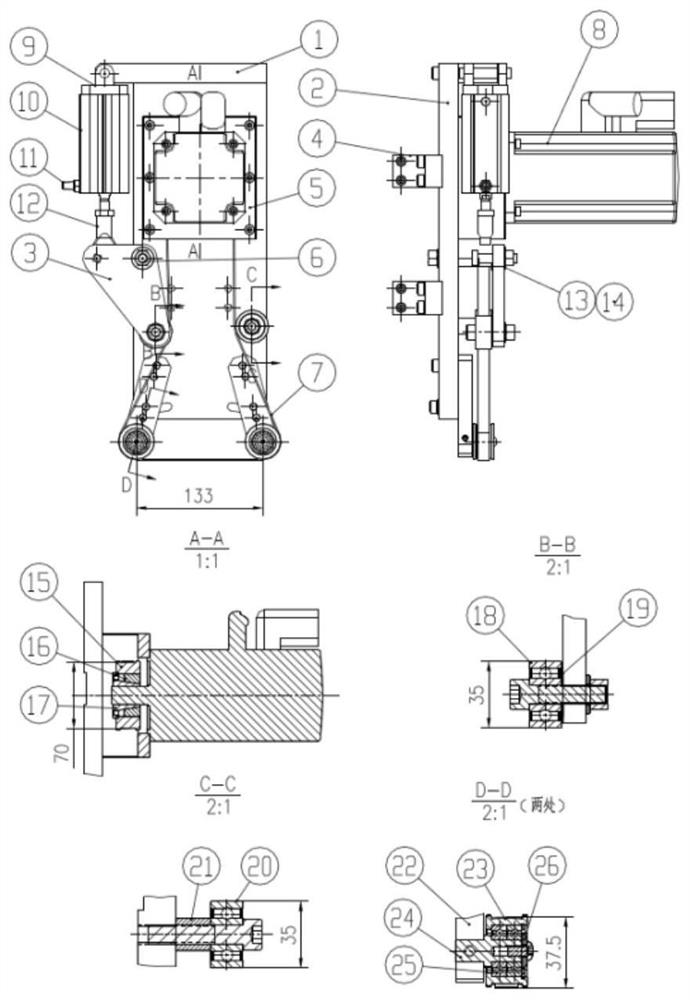

[0036] Among them, such as Figure 5 As shown, the feeding device D includes two sets of material lifting mechanisms and a material moving mechanism installed on the platform at intervals. The material lifting mechanism includes a bearing with seat 7 installed on the platform, and the bearing with seat 7 is provided with a Rotary shaft 2, a driving block 3 is installed on the rotating shaft 2, and the driving block 3 is also fixedly connected with the output shaft of a driving cylinder 1, and the driving block 3 is able to rotate around the rotating shaft through the expansion and contraction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com