High-efficiency battery module detection equipment

A battery module and testing equipment technology, applied in the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of low efficiency, high probability of operation errors, and high requirements for inspectors' skill proficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

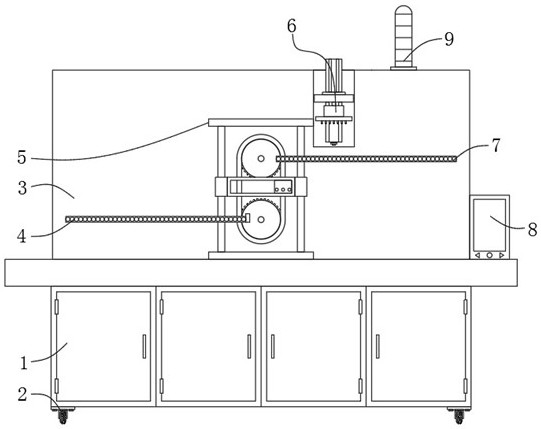

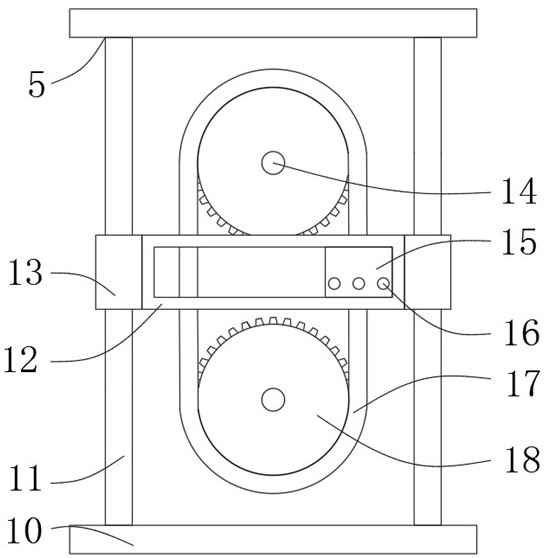

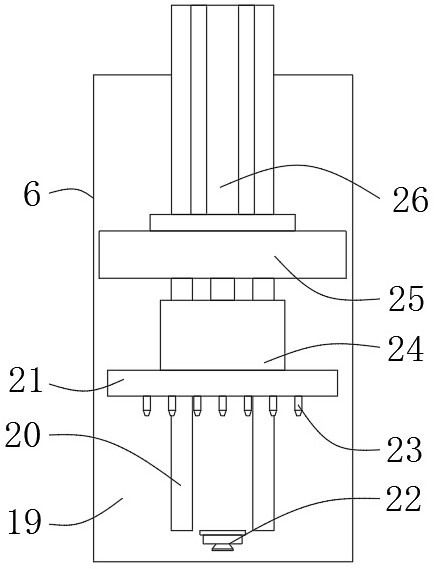

[0020] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

[0021] Depend on Figure 1-4 Given, the present invention provides the following technical solutions: a high-efficiency battery module testing equipment, including a frame 1, a frame plate 3 is installed on the top side of the frame 1, and a lifting assembly 5 is installed at the center of the frame plate 3 , the bottom side of the lifting assembly 5 is equipped with a feeding track 4, the top side of the lifting assembly 5 is equipped with a discharge track 7, the detection assembly 6 is installed on the discharge track 7, and the top side of the frame 1 is installed. The touch panel 8, the interior of the liquid crystal touch panel 8 is equipped with a PLC controller 27, the top side of the frame plate 3 is equipped with an alarm 9, the detection component 6 is electrically connected to the input end of the PLC controller 27, and the PLC contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com