Preheating device and preheating method for combined stator of plastic package motor

A technology combining stator and plastic-encapsulated motors, which is applied in the manufacture of stator/rotor bodies, household components, household appliances, etc., can solve problems such as performance reduction, heat loss, and defects, and achieve controllable preheating temperature, low cost, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

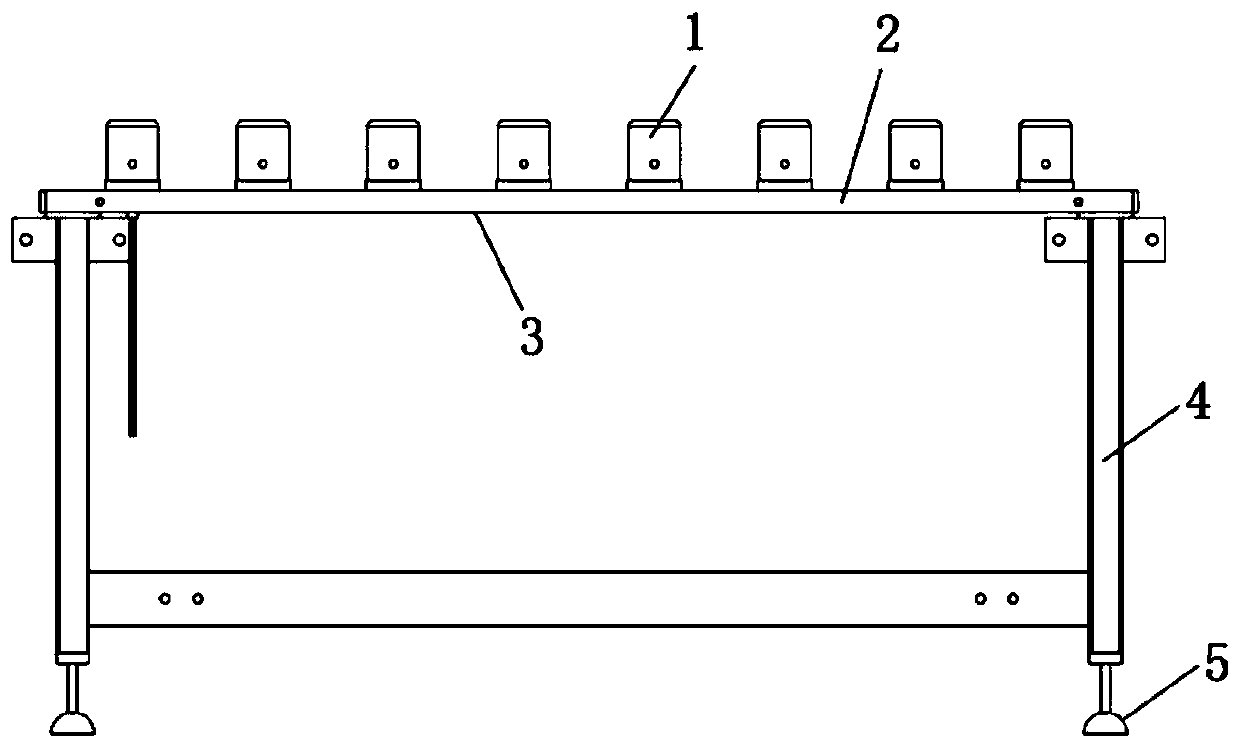

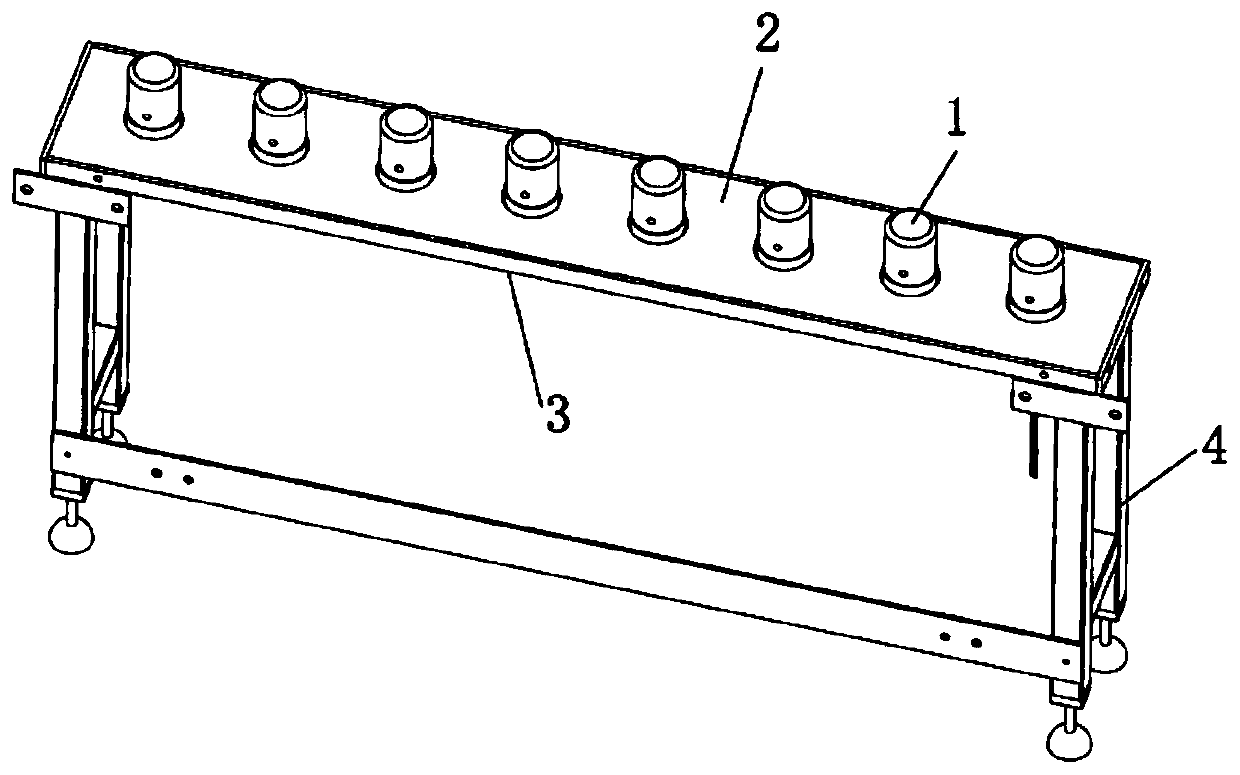

[0030] Such as figure 1 and figure 2 As shown, the present invention provides a combined stator preheating device for a plastic-encapsulated motor, which mainly includes: a stator heating core 1 , a combined core base plate 2 , a heat shield 3 , a support frame 4 and a foot 5 .

[0031] Wherein, the composite mold core bottom plate 2 can be formed as one board or a plurality of detachable boards, and when the composite mold core bottom plate 2 has multiple boards, they can be assembled on the same plane.

[0032] The shape and size of the stator heating mold core 1 is basically the same as that of the injection mold core on the injection mold for injecting the stator. The stator heating mold cores 1 are approximately cylindrical, and there are a plurality of them, which are arranged on the combined mold core bottom plate 2 . The stator heating cores 1 can be arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com