Stable cotton yarn spinning machine

A textile machine and cotton yarn technology, applied in the textile field, can solve the problems of burrs, entanglement, and entanglement of cotton threads, and achieve the effect of avoiding excessive friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

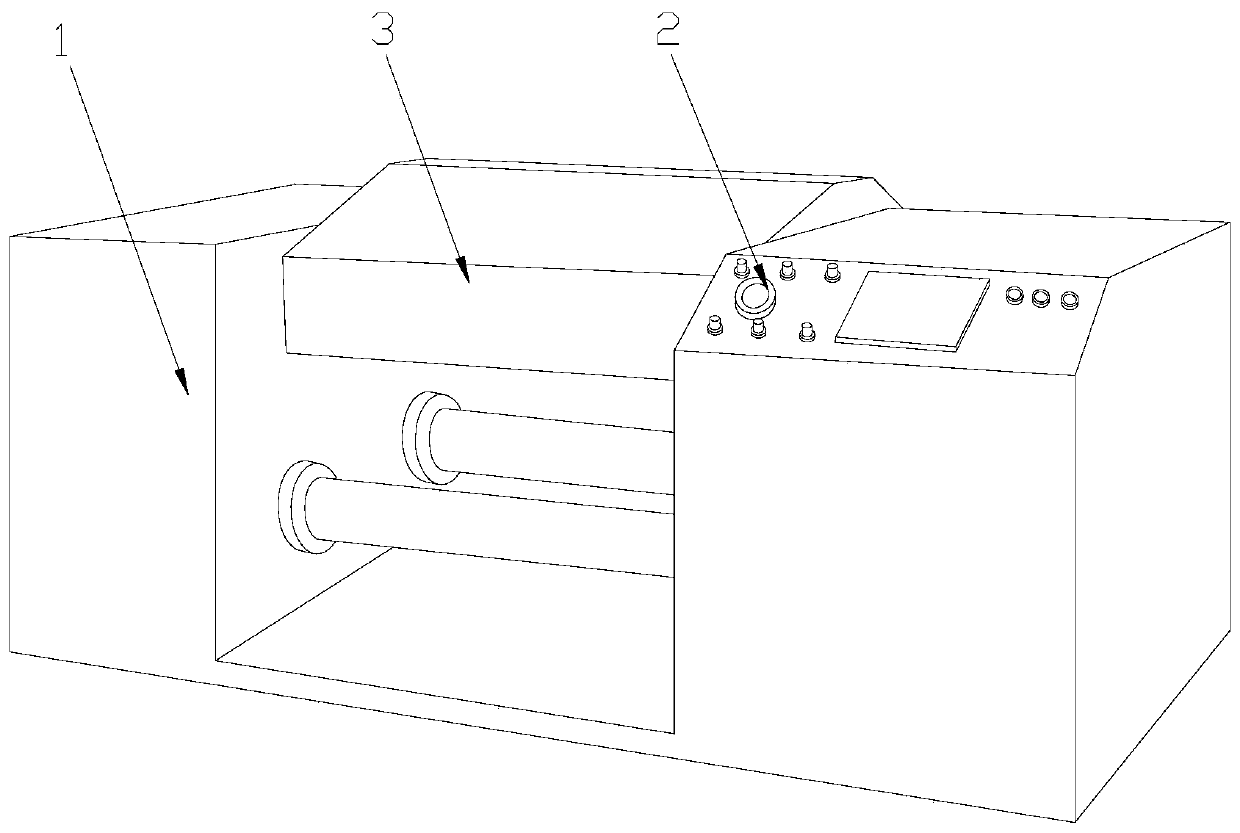

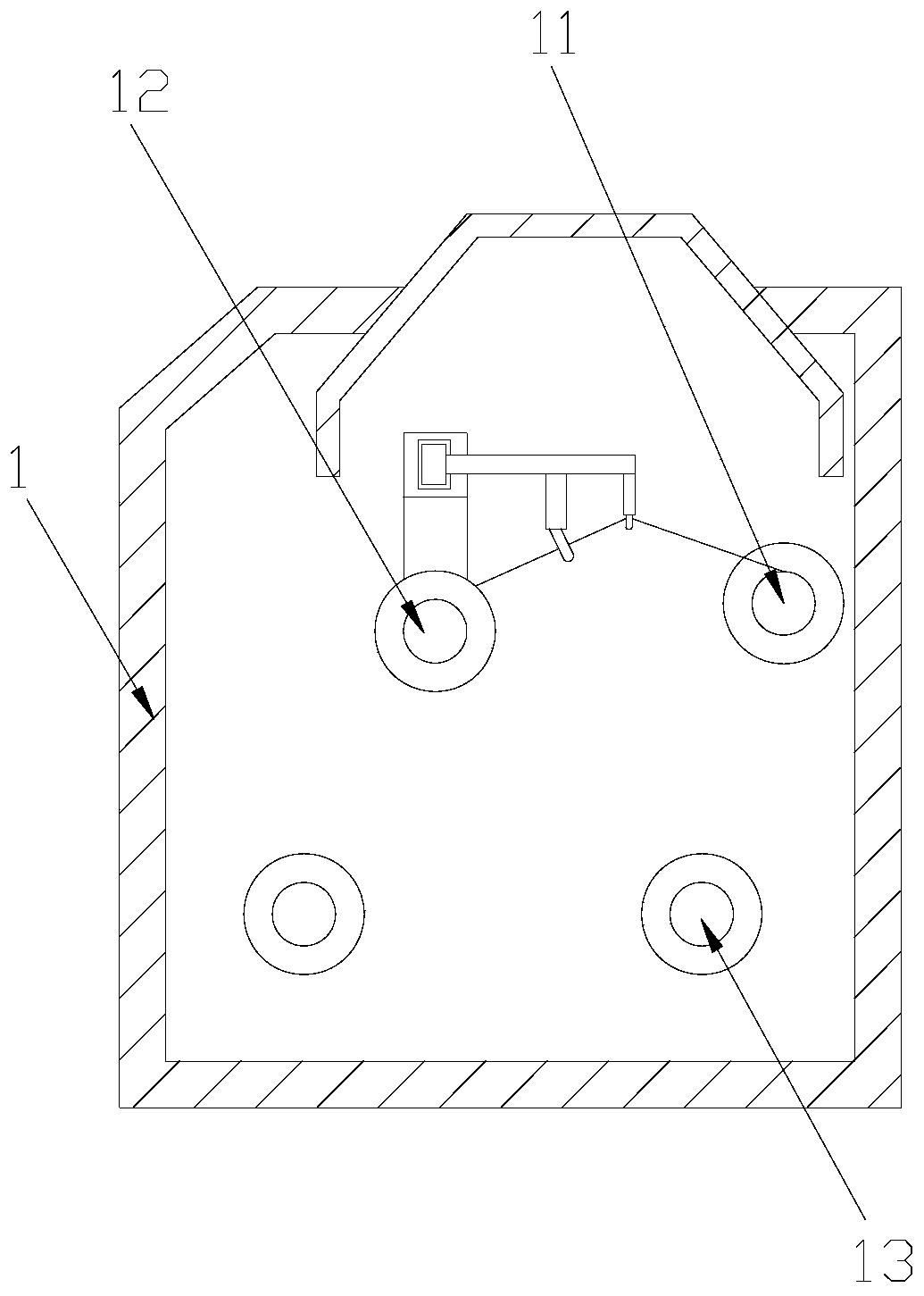

[0029] Example 1: Please refer to Figure 1-Figure 6 The specific embodiment of the present invention is as follows: its structure includes a main body 1, a top cover 2, and a control panel 3. The top cover 2 is embedded in the middle of the top of the main body 1, and the control panel 3 is located at the top side of the main body 1; The main body 1 includes a drum 11, a winding roller 12, and a wire waste roller 13, the drum 11 is installed on the top rear end of the main body 1, and it is characterized in that: the winding roller 12 is embedded in the top front end of the main body 1, Two wire waste rollers 13 are provided, and the wire waste rollers 13 are installed at the bottom of the main body 1 .

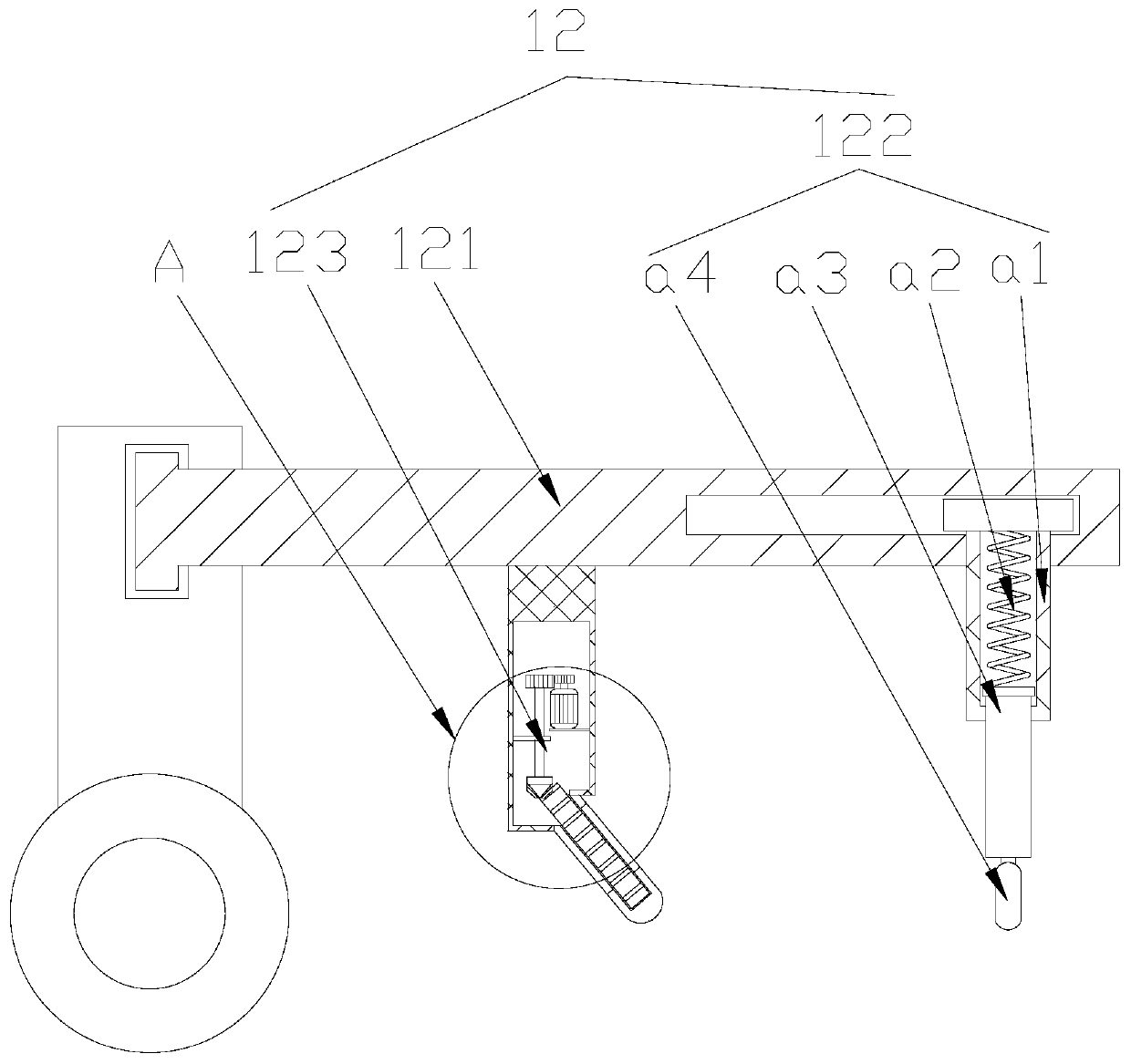

[0030] Include support column 121, wire device 122, hair removal device 123 in the described winding roller 12, described support column 121 is welded on the both sides of winding roller 12, and described wire device 122 is installed on the end of support column 121, so The...

Embodiment 2

[0036] Example 2: Please refer to Figure 7-Figure 9 The specific embodiment of the present invention is as follows: the hair removal device 123 includes a fixed column c1, a motor c2, and a hair removal block c3, and a motor c2 is installed inside the fixed column c1, and the motor c2 in the fixed column c1 is vertical Installation, the hair removal block c3 is arranged at the bottom of the fixed column c1, the angle between the hair removal block c3 and the fixed column c1 is 120 degrees, and the motor c2 is movably matched with the hair removal block c3, which is beneficial to the Cotton thread for hair removal.

[0037]The hair removal block c3 includes an engaging groove c31, a gear c32, and a deburring device c33. The engaging groove c31 is located at the upper end of the hair removal block c3, and the gear c32 is installed inside the hair removal block c3. The pressing device c33 is embedded in the inner side of the gear c32. There are three pressing devices c33 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com