Glass material with low loss and low piezoelectric coefficient d33 in high frequency band of 20-60 GHz

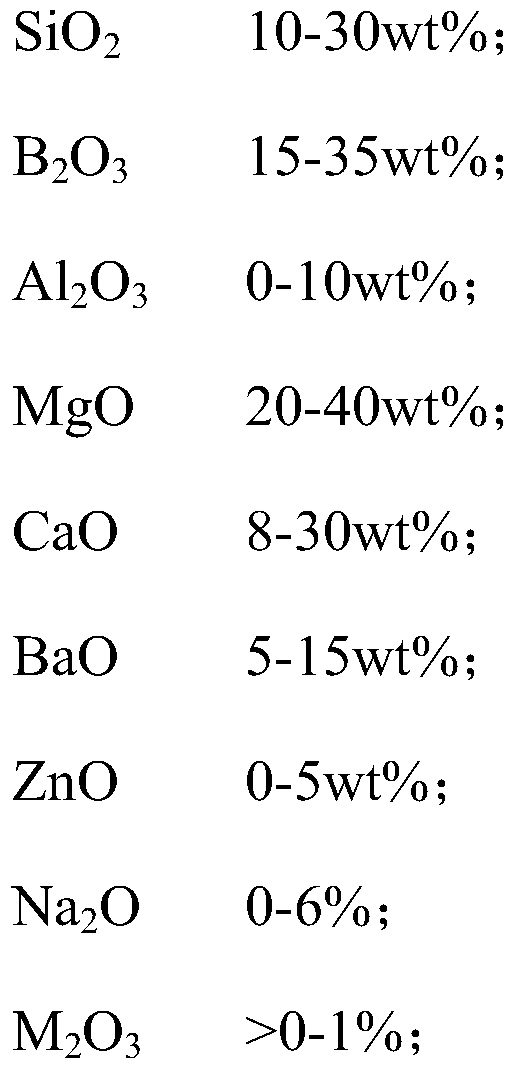

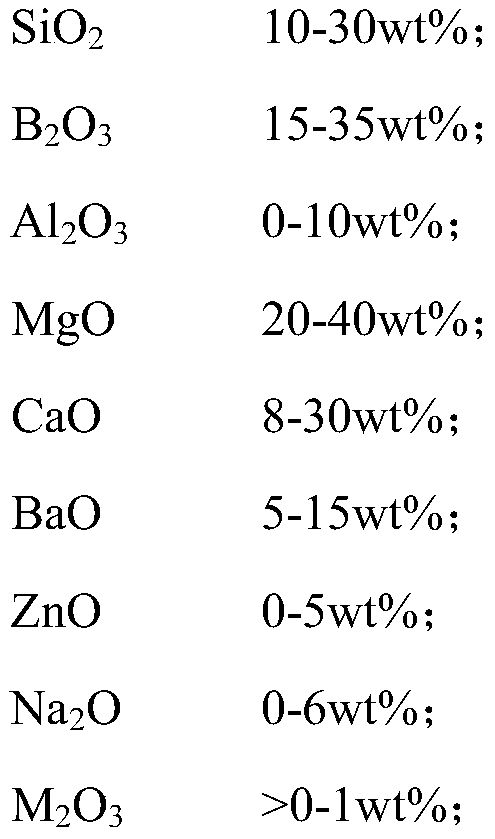

A glass material and low-loss technology, which is applied in the field of high-frequency low-loss and low-voltage electric coefficient glass materials and their preparation, can solve the problems of large high-frequency dielectric loss of substrates, poor product performance stability, and higher requirements for sintering processes. Achieve low dielectric constant, low dielectric loss, lower softening point temperature and the effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment further illustrate the present invention.

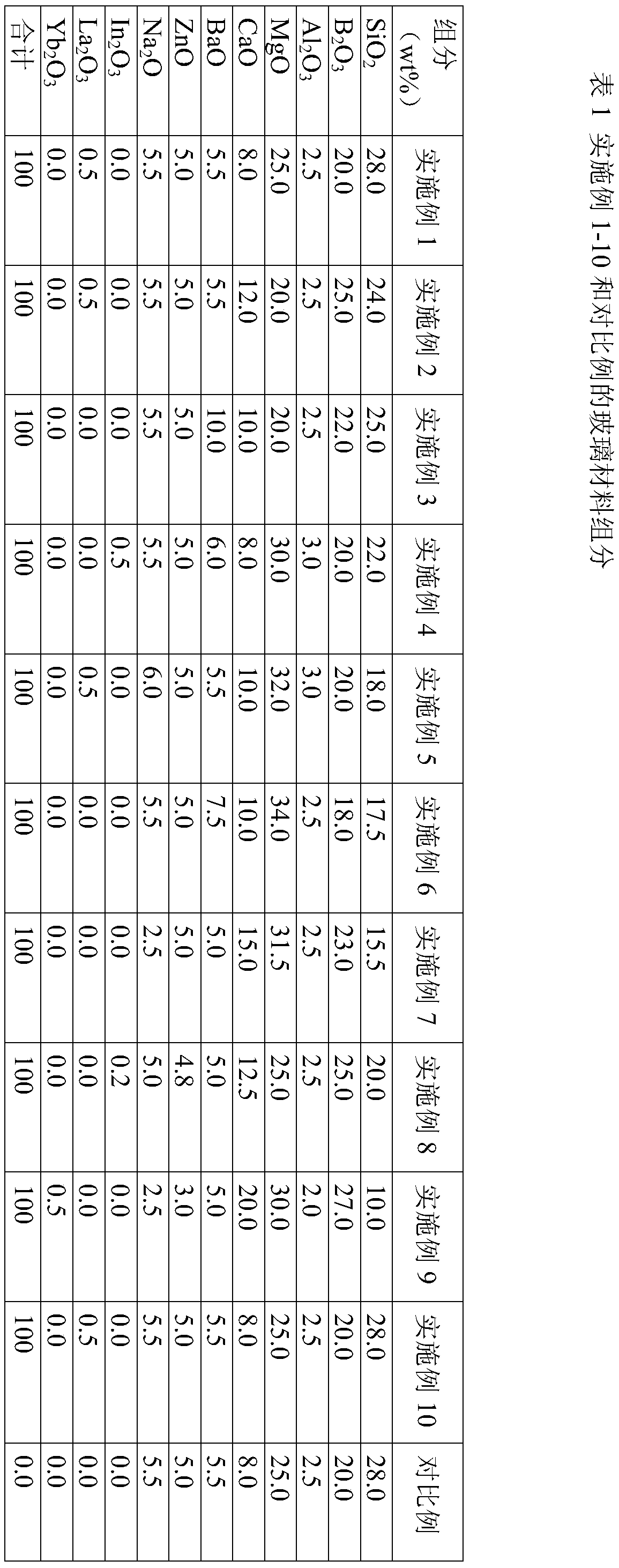

[0022] Embodiment 1-10 and comparative example:

[0023] Accurately weigh the raw materials according to the glass components shown in Table 1, dry mix them evenly, put the mixed raw materials into a platinum crucible, melt at 1200-1400°C for 2 hours, pour the molten glass into dry quenching Rapid cooling and quenching was carried out in the machine, and the obtained glass block was added with pure water of 2 times the quality of the glass and alumina grinding balls of 5 times the quality for ball milling and dispersion, dried and sieved to obtain Examples 1-10 and Comparative Examples glass powder.

[0024] Add 1.5wt% PVA by mass to the glass frits of Examples 1-10 and Comparative Example, dry press molding, and then sinter at 650° C. and keep warm for 2 hours to obtain the ceramic sheets of Examples 1-10 and Comparative Example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com