High-frequency low-loss glass ceramic material and preparation method thereof

A glass-ceramic, low-loss technology, used in glass manufacturing equipment, glass molding, manufacturing tools, etc., to achieve the effect of reducing the number, softening point temperature and dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment further illustrate the present invention.

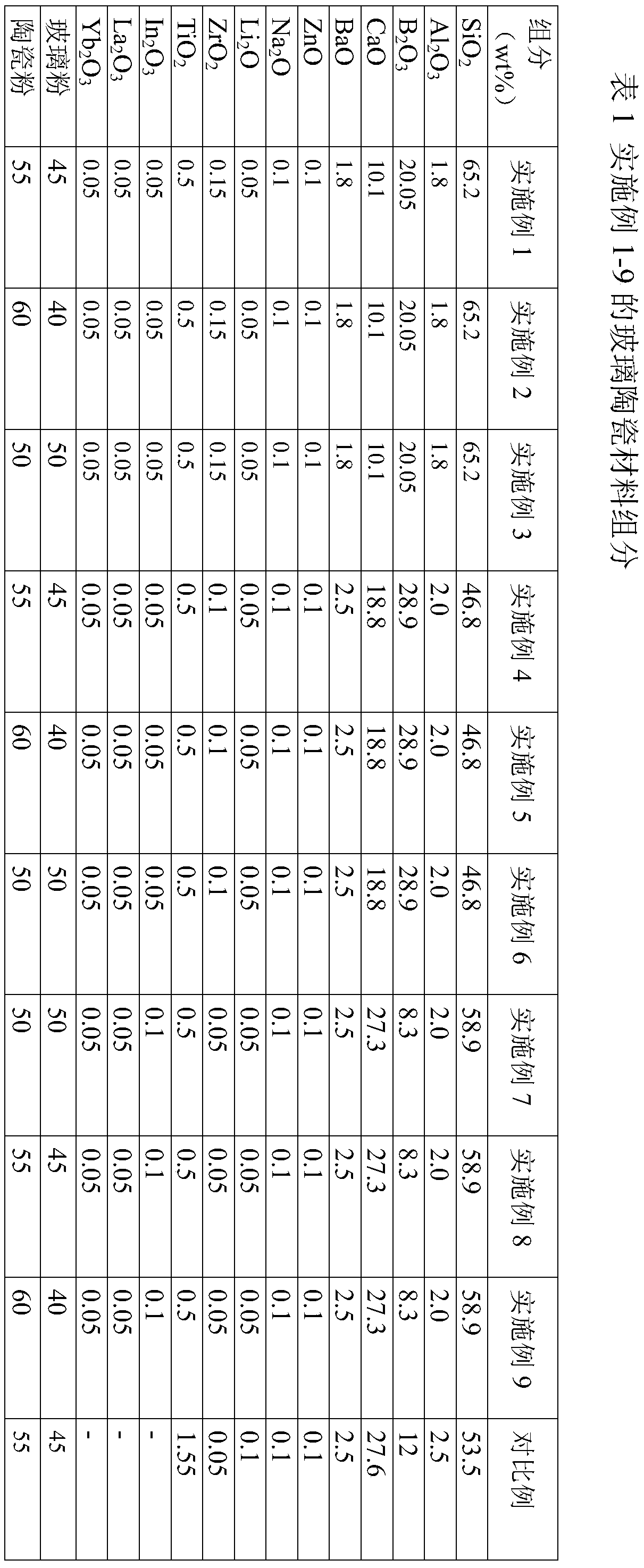

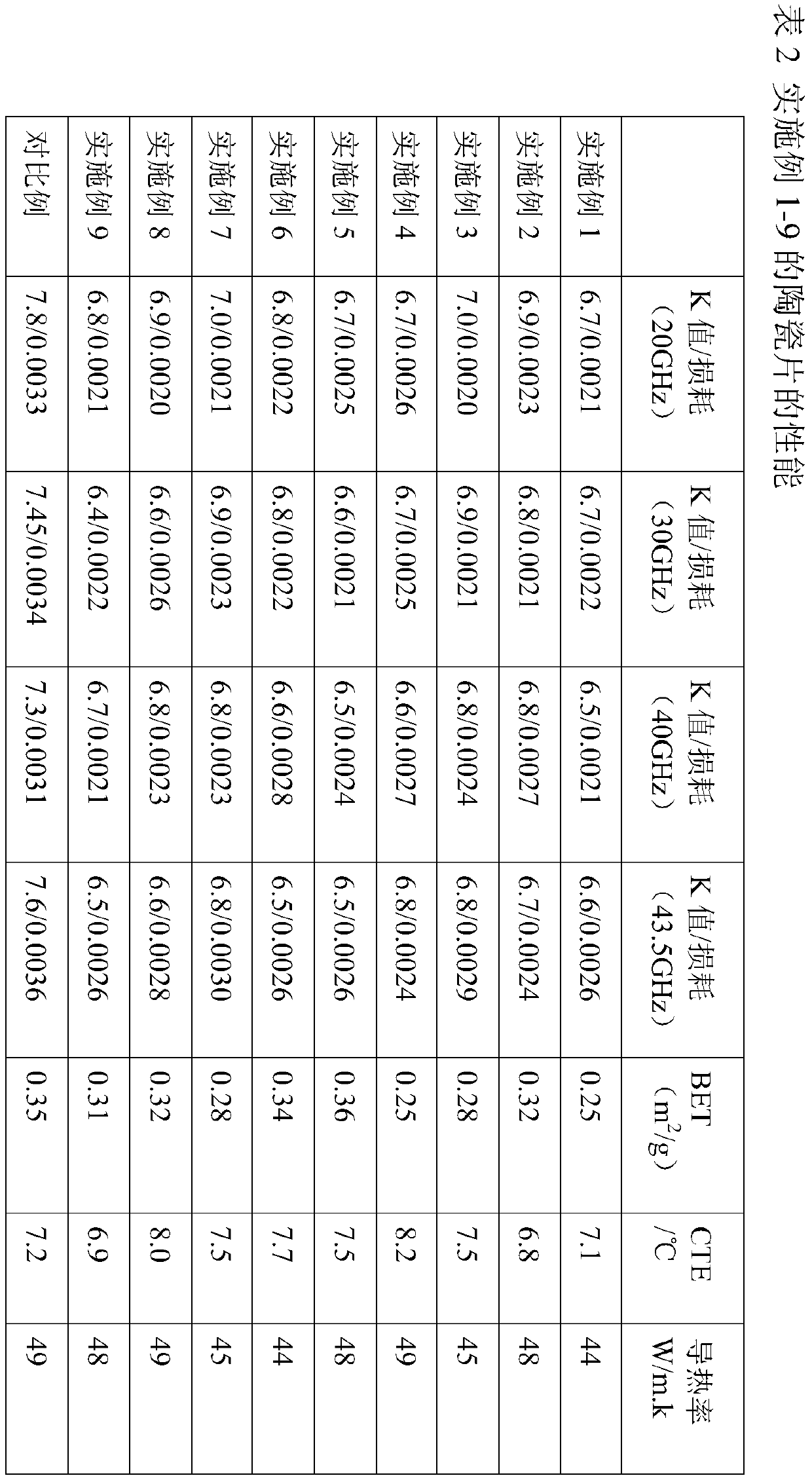

[0025] Embodiment 1-9 and comparative example:

[0026] According to the formula of each component of glass ceramics shown in Table 1, accurately weigh the raw materials, dry mix them evenly, melt them at 1300 ° C, keep them warm for 1.5 hours, pour the molten glass into a dry quenching machine for rapid cooling Quenching, adding 2-3 times the glass quality of pure water and 3-5 times the quality of alumina grinding balls to the obtained glass blocks for ball milling and dispersing, drying and sieving to obtain the samples of Examples 1-9 and Comparative Examples glass powder.

[0027] According to the ratio of glass powder and nano-ceramic powder shown in Table 1, weigh the corresponding glass powder and nano-ceramic powder, dry mix them evenly, then sand-mill and disperse the evenly mixed glass-ceramic powder, dry and sieve, The corresponding CBB-SAA glass-ceramic powders of Examples 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| loss value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com