A polishing device for textile fabrics

A technology for textile fabrics and placing boxes, applied in textiles and papermaking, fabric surface trimming, springs/shock absorbers, etc., can solve problems affecting processing efficiency, reduce enterprise production costs, increase processing difficulty, etc., and achieve practicality Strong, efficiency-enhancing, and difficulty-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

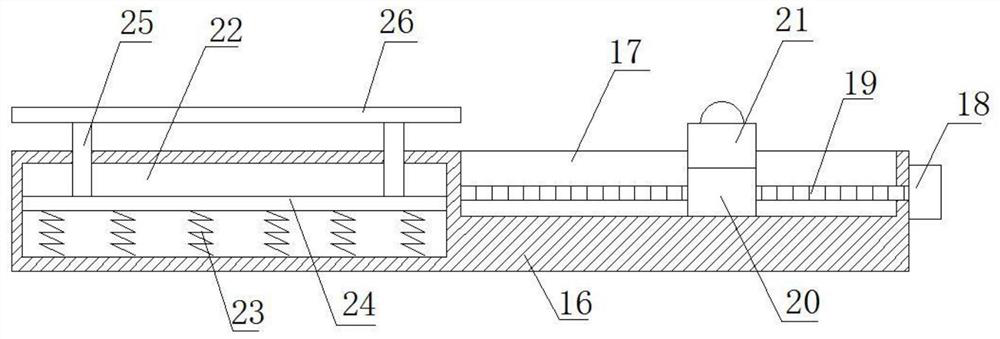

[0024] see Figure 1-3 , in an embodiment of the present invention, a textile fabric polishing device includes a placement box 1, the inner bottom of the placement box 1 is provided with a shock absorbing mechanism 5, and a lifting mechanism 6 is installed on the shock absorbing mechanism 5, The lifting mechanism 6 is equipped with a support plate 8 through several pillars 7, the support plate 8 is provided with a workbench 9, the left and right ends of the workbench 9 are provided with a support 10, and the support 10 is provided with a guide wheel 11, The upper side of described workbench 9 is provided with frame 12, and on described frame 12, the first electric telescopic mechanism 13 is installed symmetrically, and the lower end of described first electric telescopic mechanism 13 is equipped with upper polishing mechanism 14, works The upper side of the table 9 is provided with a lower polishing mechanism 15, the upper polishing mechanism 14 and the lower polishing mechani...

Embodiment 2

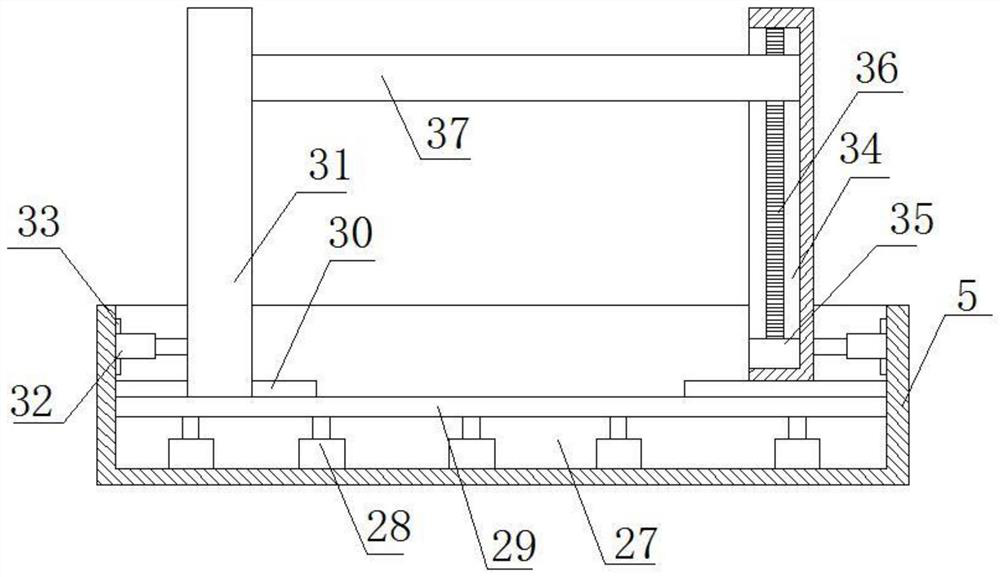

[0028] On the basis of embodiment one, refer to image 3 , the shock absorbing mechanism 5 includes a shock absorbing seat, the inside of the shock absorbing seat is provided with a shock absorbing cavity 27, and the inside of the shock absorbing cavity 27 is provided with several vertical shock absorbing mechanisms 28, and the vertical shock absorbing The upper end of mechanism 28 is equipped with damping plate 29, and the upper side of described damping plate 29 is provided with horizontal slide rail 30 symmetrically, and described lifting mechanism 6 is installed on the horizontal slide rail 30, and the outside of lifting mechanism 6 is provided with Horizontal shock absorbing mechanism 32, the outer end of described transverse shock absorbing mechanism 32 is connected with shock absorbing chamber 27 through vertical slide rail 33, the setting of this mechanism, when device works or transports, can realize the shock absorption to device, prolong The service life of the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com