Fabricated box girder bridge and anti-seismic structure thereof

An anti-seismic structure and prefabricated technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the design method of reinforced concrete lateral limit stoppers, the detailed structure and its performance objectives, clearly stipulate, ignore the design of stoppers, and cannot Give full play to the block function and other issues to achieve the effect of ensuring the shear damage resistance, improving the shear resistance, and improving the shear damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

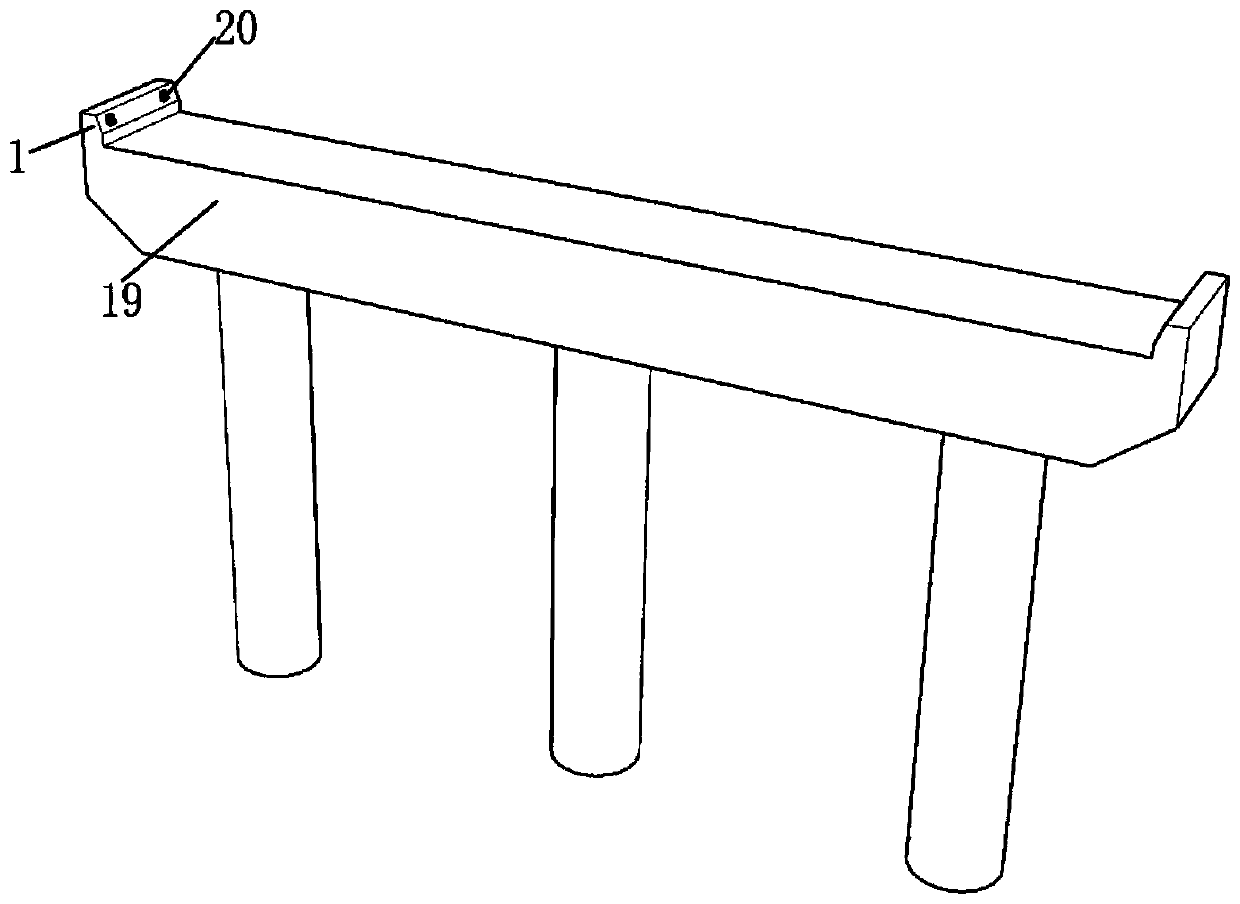

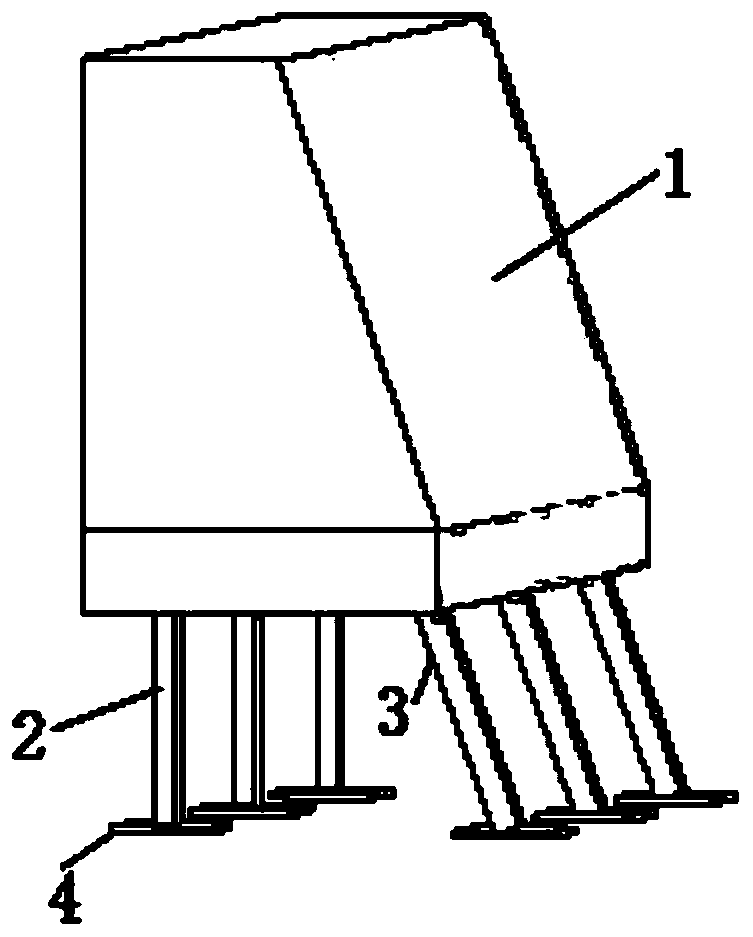

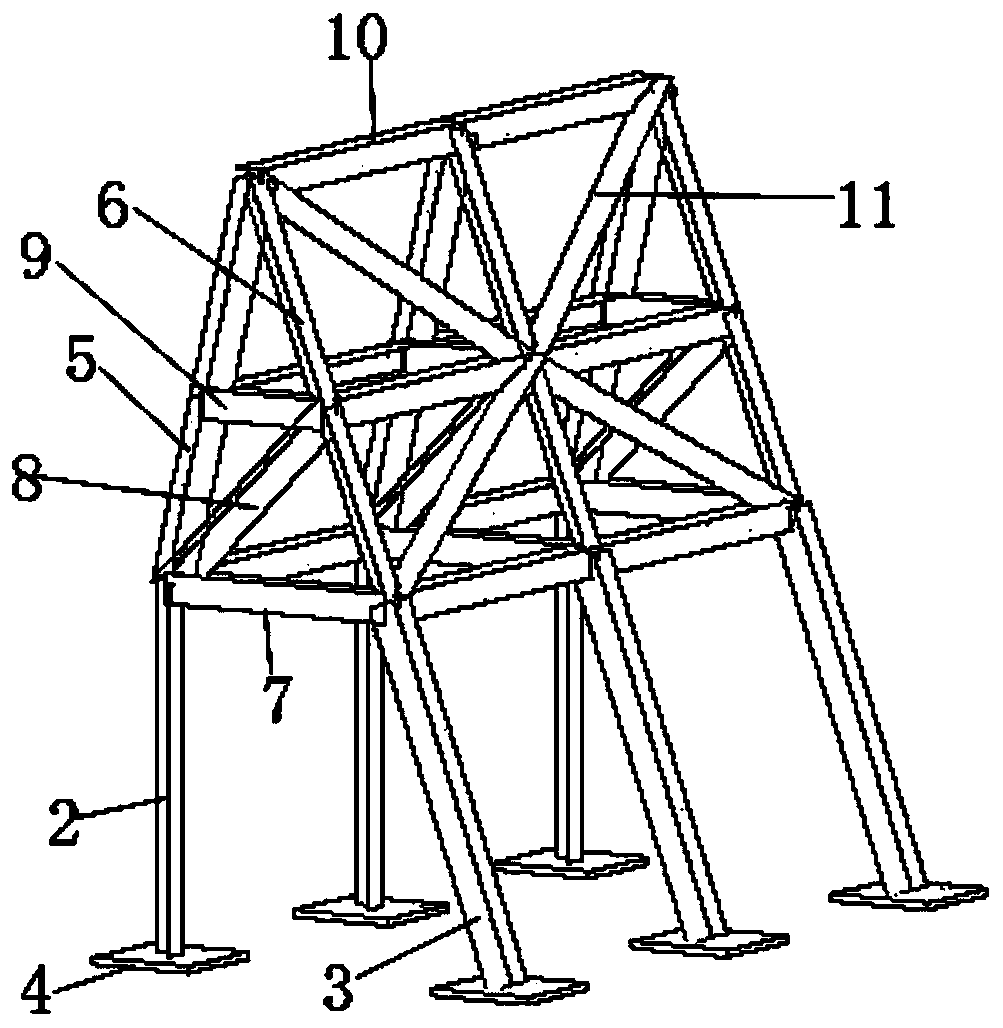

[0048] The anti-seismic structure of the assembled box girder bridge of the embodiment of the present invention includes a block 1, a vertical bar 2, a diagonal bar 3, a foot 4, a skeleton pressure bar 5, a skeleton tie rod 6, a skeleton large beam 7, a skeleton brace 8, and a small skeleton Crossbeam 9, framework longitudinal beam 10he framework vertical diagonal brace 11. See details Figure 1 to Figure 5 as well as Figure 6(a) ~ Figure 6(c) . Such as figure 1 As shown, the block 1 is located on both sides of the cover beam 19 , and the outer edge of the block 1 is flush with the edges at both ends of the cover beam 19 . A rubber pad 20 of 200×200×20 mm is pasted on the block 1, and two rubber pads 20 are arranged on one side of one block. Such as Figure 3 ~ Figure 5 as well as Figure 6(a) ~ Figure 6(c) As shown, the vertical bar 2, the oblique bar 3, the feet 4, the skeleton pressure bar 5, the skeleton tie rod 6, the skeleton large beam 7, the skeleton diagonal br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com