Bridge-dismounting construction method for prestressed concrete continuous beam

A construction method and concrete technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve water pollution and other problems, achieve high safety factor, ensure normal traffic conditions, and avoid construction accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

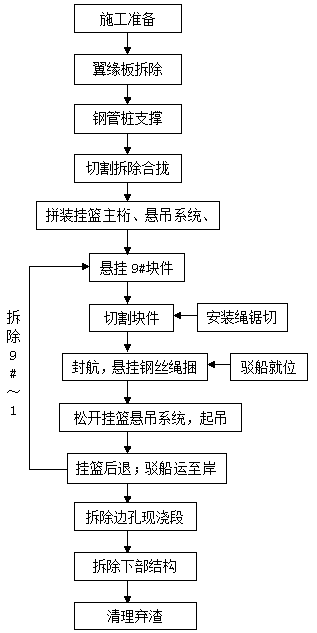

Image

Examples

Embodiment

[0012] Embodiment: The prestressed concrete continuous girder bridge demolition construction method in this embodiment includes the following steps, specifically in conjunction with a certain engineering example to illustrate:

[0013] River channel cleaning: Large floating cranes and barges are mainly used for hoisting to remove the superstructure of the main bridge. Therefore, the river channel on the transportation route needs to be cleaned before dismantling to ensure that large floating cranes and barges can pass on the transportation route.

[0014] When cutting the upper continuous beam, it is necessary to install steel pipe piles. Since there are rubbish such as gravel in the river, the location where the steel pipe piles are installed must be cleaned to ensure that the steel pipe piles can be driven in.

[0015] Removal of continuous beam ancillary facilities: before the main structure is cut and removed, structures such as curbs, kicks, steel guardrails, lamp posts, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com