Fireproof heat insulation board and manufacturing method thereof

A technology of fire-proof insulation board and production method, which is applied in the directions of heat preservation, fire prevention, building components, etc., can solve the problem that the insulation board cannot fully meet the reinforced strength index, affects the flatness and thickness of the subsequent protective layer, and the distance between the steel mesh sheets is difficult to control. control and other issues, to achieve considerable economic effects, optimization effects, and obvious quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

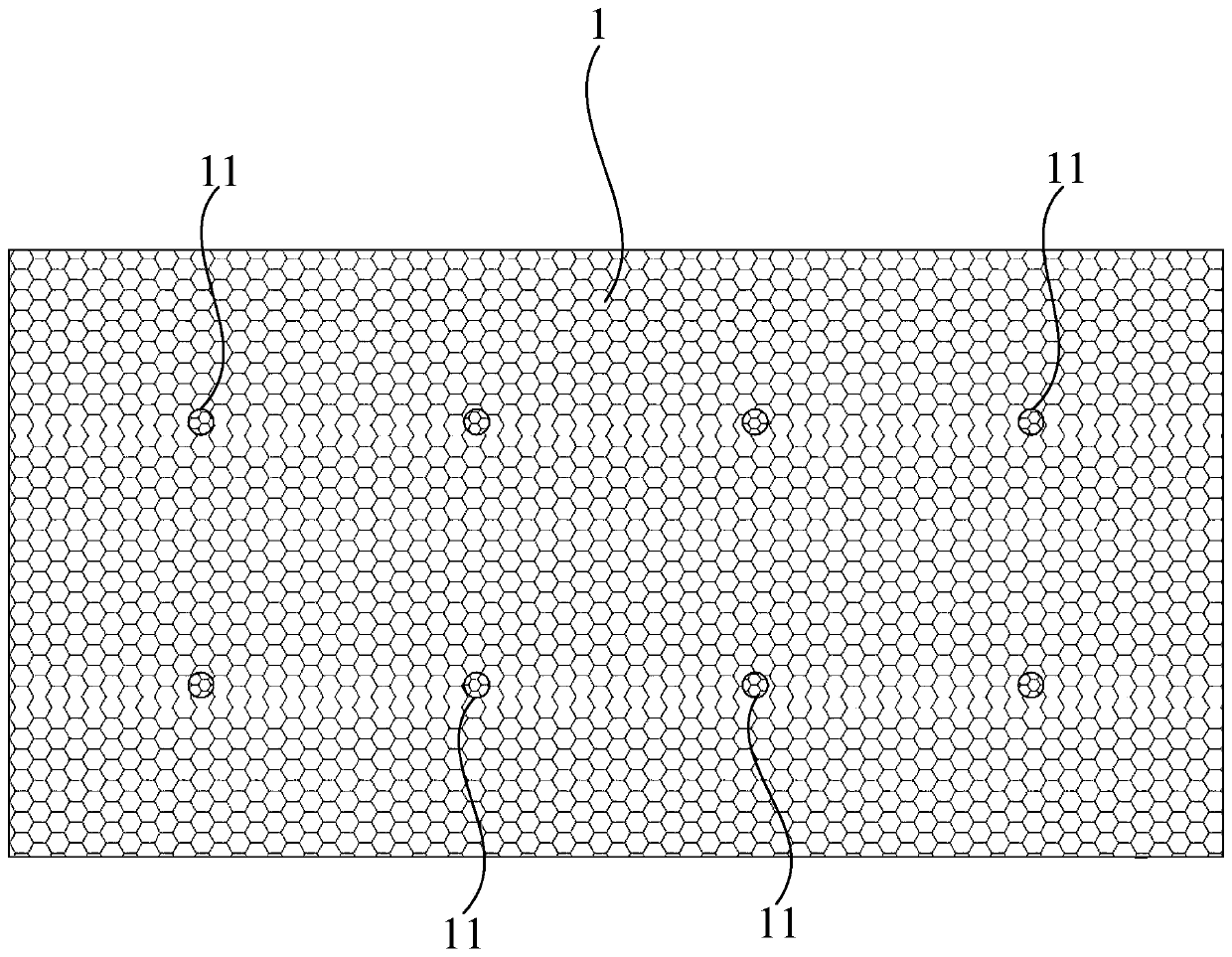

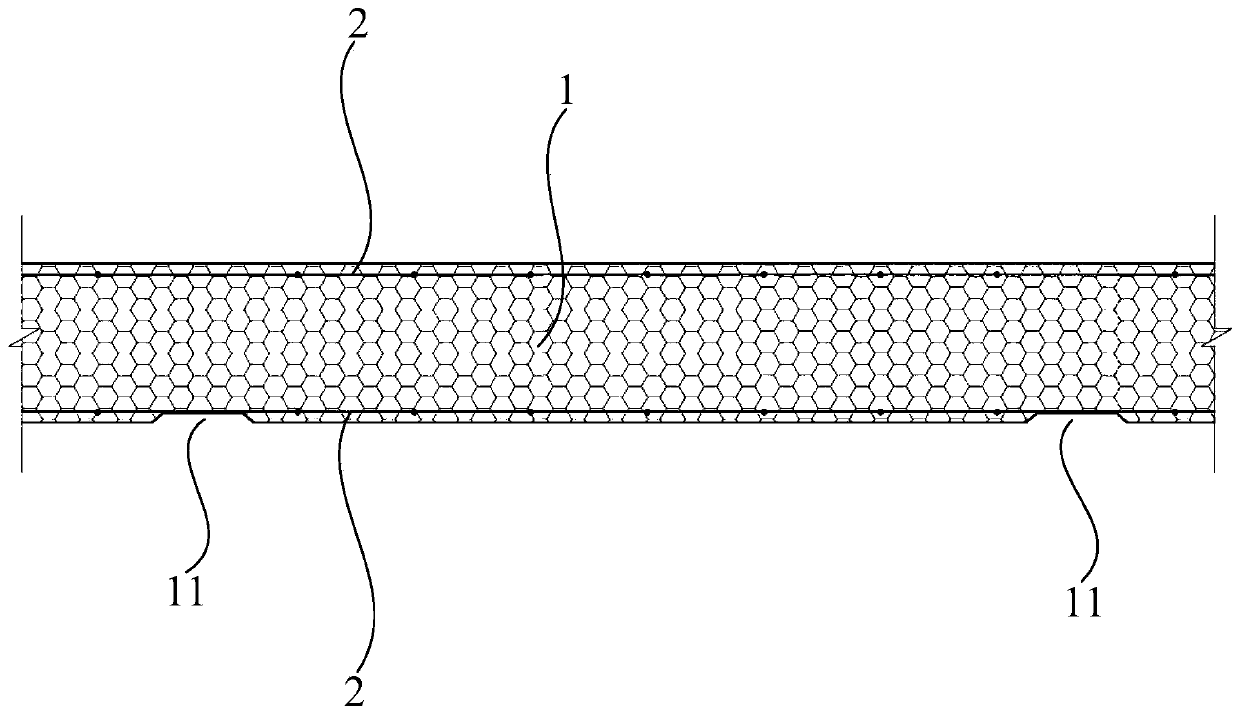

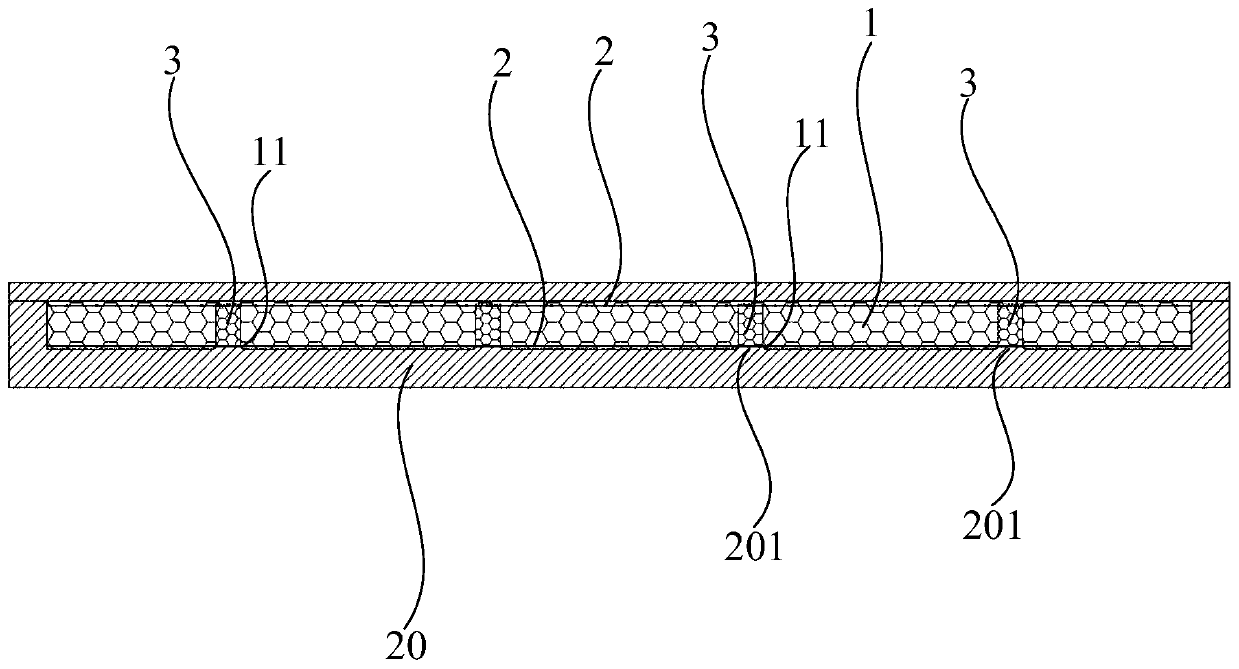

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, this embodiment discloses a fireproof heat preservation board, which includes a class A fireproof heat preservation board body 1, several steel wire mesh pieces 2 and several limit parts 3, and one side of the class A fireproof heat preservation board body 1 has several A groove 11 for receiving the anchor disc 101 in the anchor 10.

[0040] When the fireproof heat preservation board is installed and used, the anchor piece 10 will pass through the main body 1 of the class A fireproof heat preservation board to realize fixing. Through the groove 11, the anchor plate 101 will be embedded into the groove 11 when it is attached to the main body 1 of the class A fireproof insulation board, so that the anchor 10 will no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com