Prevention and control method for deep pressure relief and shallow reinforcing of advanced coal body of rock burst mine

A technology of rock burst and coal mass, which is applied in surface mining, underground mining, shaft lining, etc., can solve the problems of destroying original support, large deformation of roadway, and many personnel and equipment, so as to improve integrity, stability, Improve the support strength and increase the effect of support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

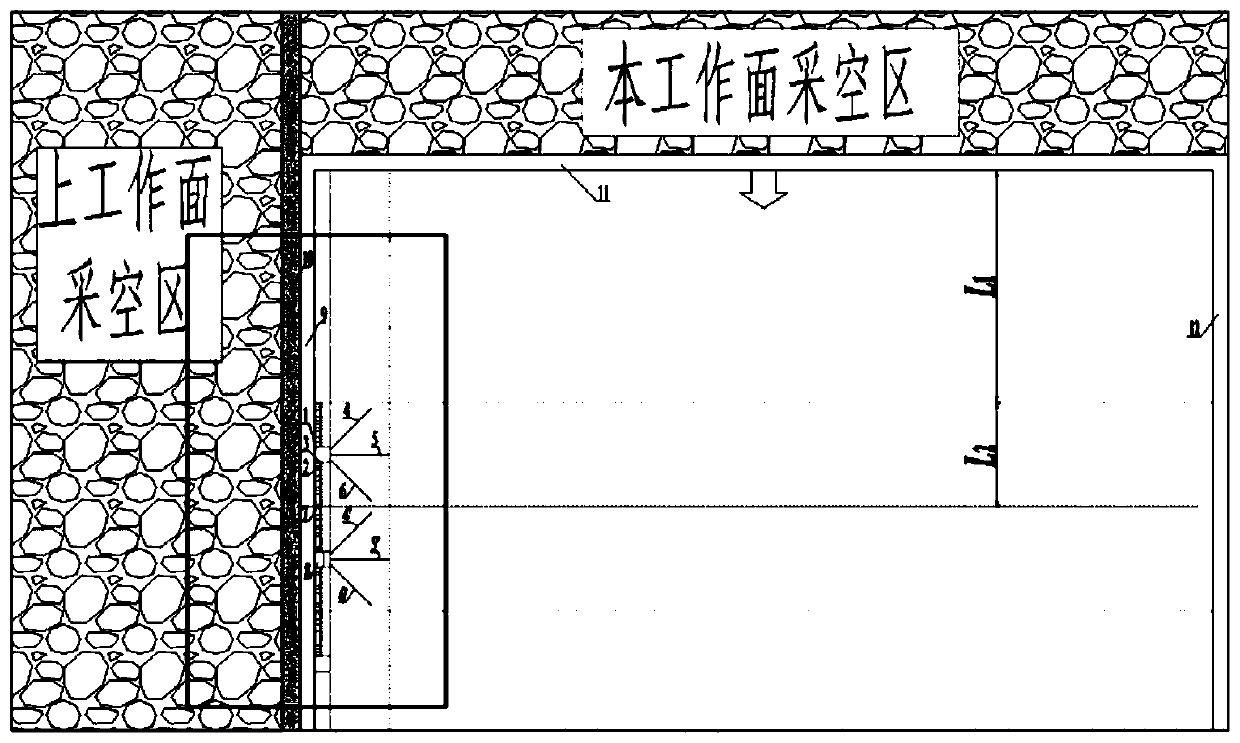

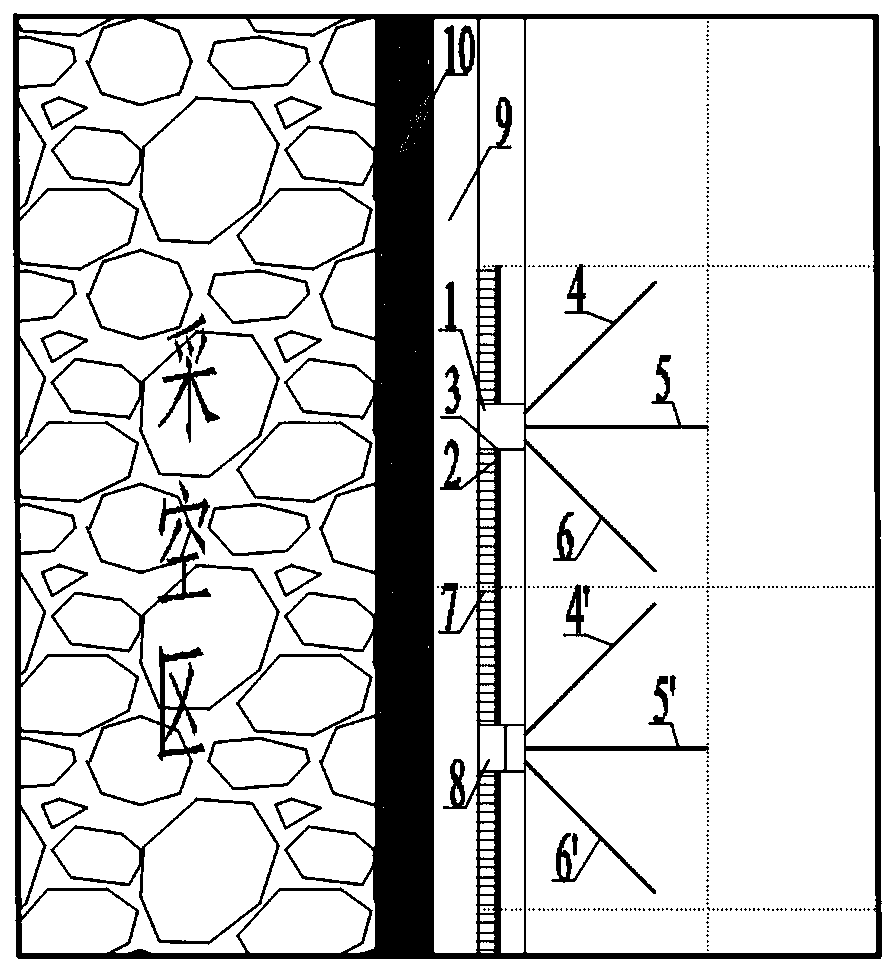

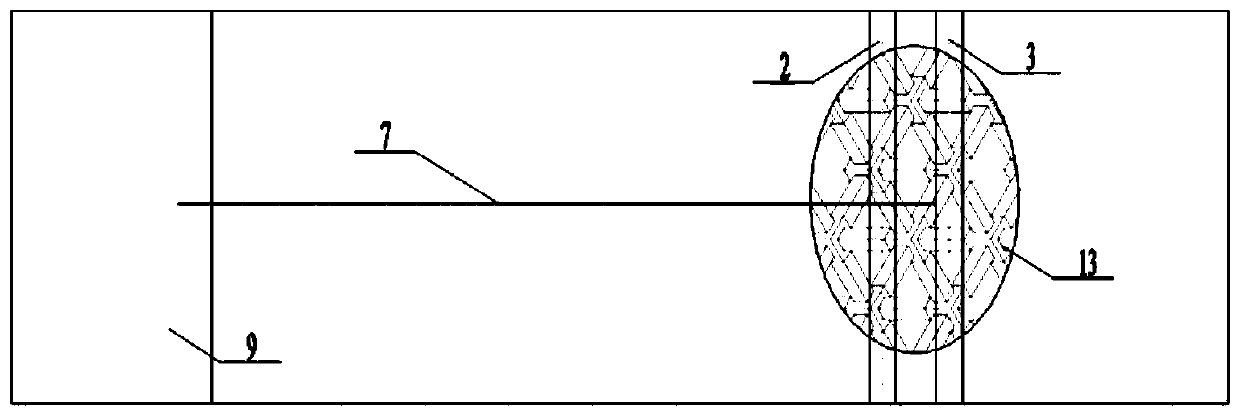

[0022] Firstly, before mining at the working face, firstly cut the eye at the distance L 1 +L 2 range in L 2 To construct pressure relief chambers for intervals, the front and back adjacent pressure relief chambers are used as a unit, and the following construction steps are followed until the completion of the advanced L 1 +L 2 All deep pressure relief and shallow reinforcement works within the scope, where L 1 is the leading influence range of the working face, L 2 is the pressure relief step. Such as Figure 1 to Figure 3 As shown, when the present invention is actually implemented, it works at a distance of L 1 The upper pressure relief chamber 1 is constructed at the position of , separated from it by L 2 Construction of the pressure relief chamber 8 at the position of the pressure relief chamber 8, the structure unit of the present invention con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com