Comprehensive stage construction method for super-large-span underground cavern of fractured rock mass

A technology for fissured rock mass and cavern, which is applied in underground chambers, earthwork drilling, mining equipment, etc., can solve the problems of inappropriate standard design method, low bearing capacity of supporting structure, and less attention to calculation, and achieve design The effect of universal method, efficient and safe excavation, and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

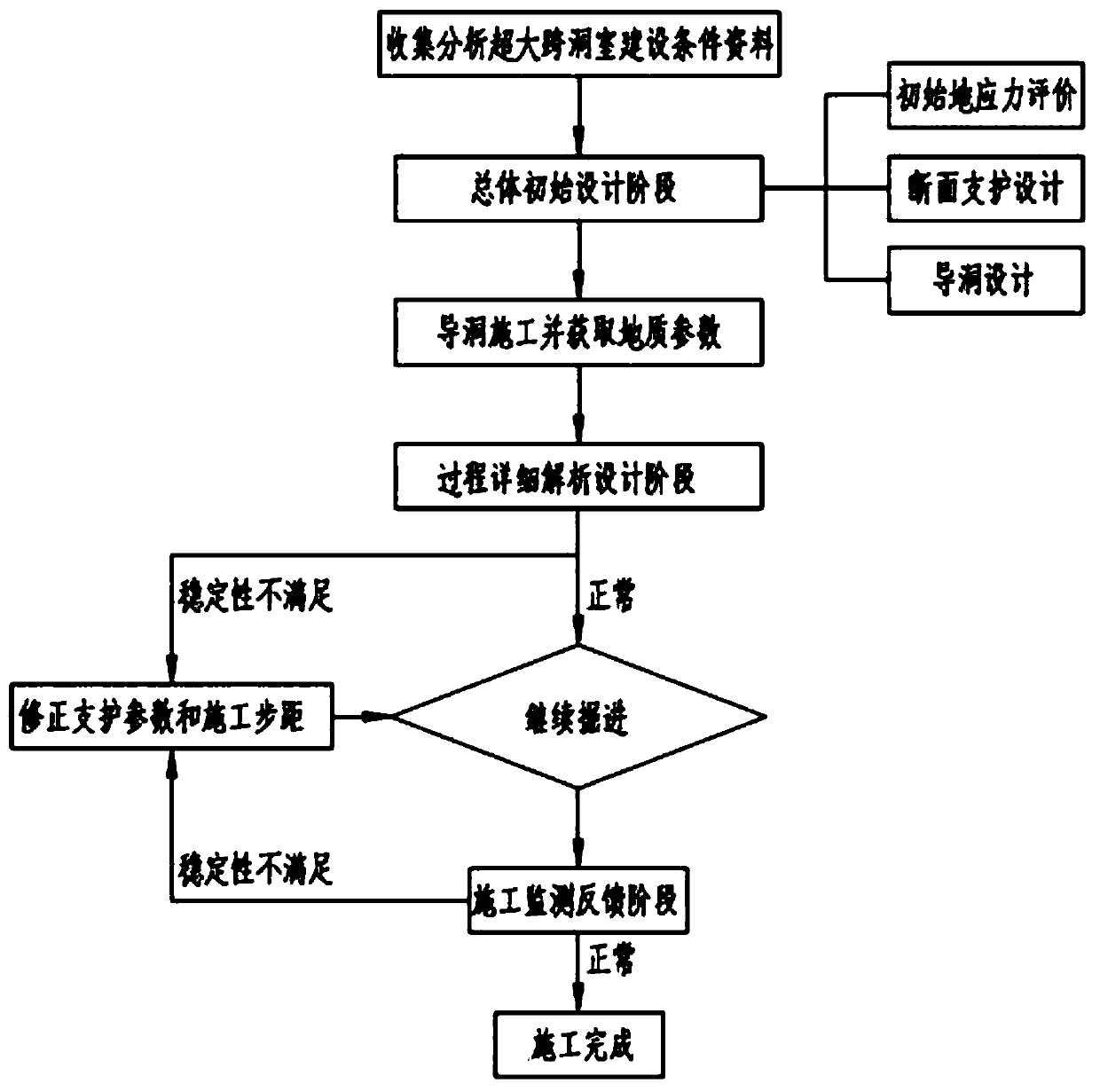

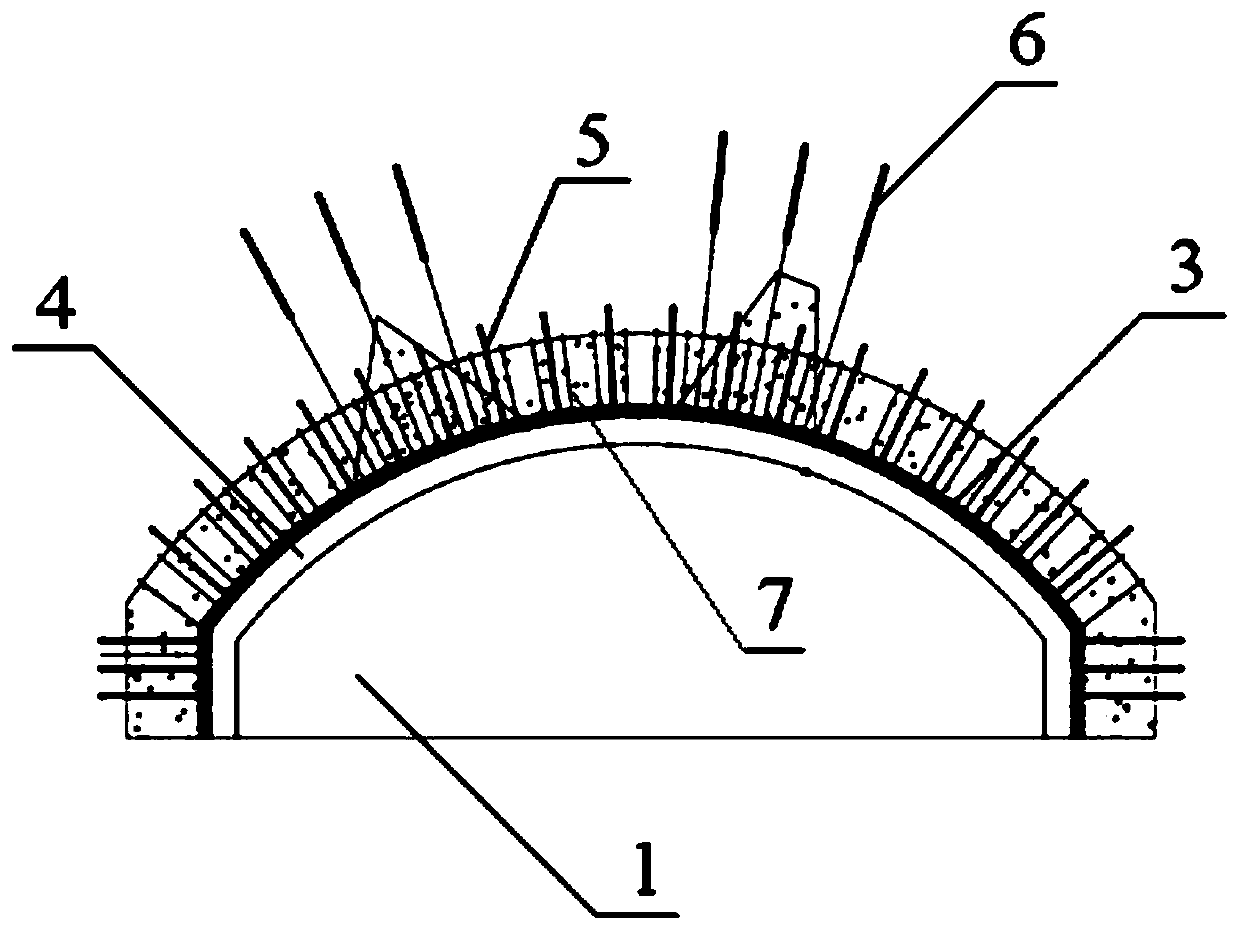

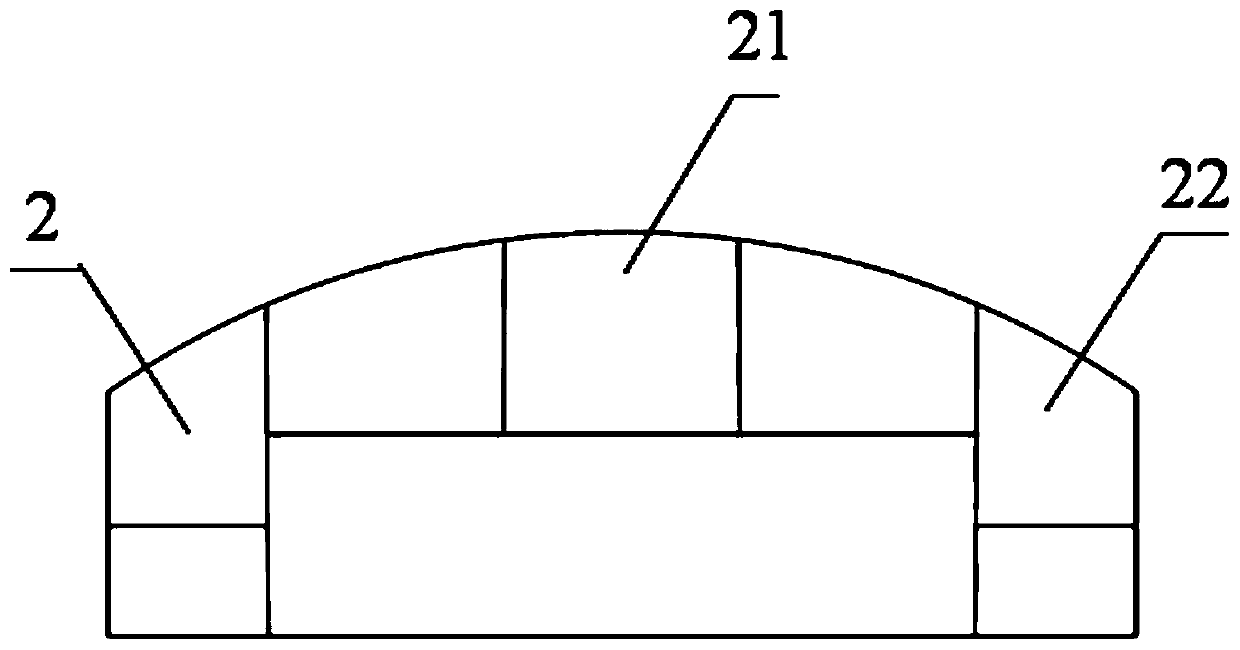

[0045] Embodiment 1: as Figures 1 to 3 As shown, a kind of comprehensive construction method in the stage of lower cavern with a span of 60 meters in the fractured rock mass comprises the following steps:

[0046] Step 1: Collect and analyze construction condition data of ultra-large-span underground caverns before construction;

[0047] Step 2: The overall initial design stage at the initial stage of construction, including initial ground stress evaluation, initial support structure design for the section, and pilot tunnel design;

[0048] Step 3: Carry out pilot tunnel and support construction and obtain the actual geological parameters of the cavern;

[0049] Step 4: In the construction process, analyze the design stage in detail, and mainly use the discrete element method to judge the stability of the excavation and surrounding rock in combination with the actual geological parameters in Step 3; when the stability meets the conditions, continue construction; when the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Circumferential spacing | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com