Automatic dust removal and damping process for refrigerating machine

A technology for automatic dust removal and refrigerators, applied in refrigerators, refrigeration and liquefaction, springs/shock absorbers, etc., can solve problems such as inability to affect use, elimination of vibration, and inability to clean up dust in refrigeration devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

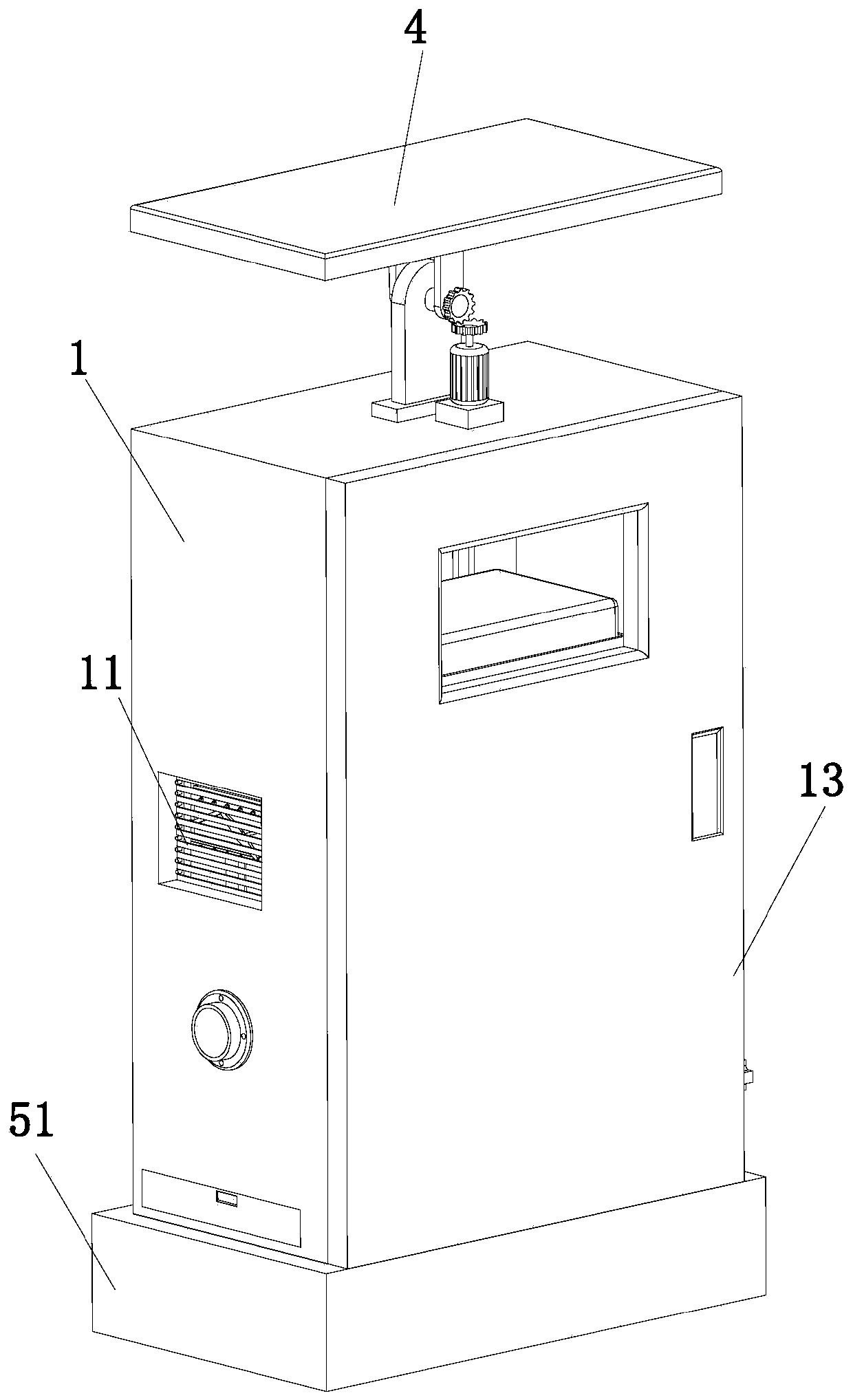

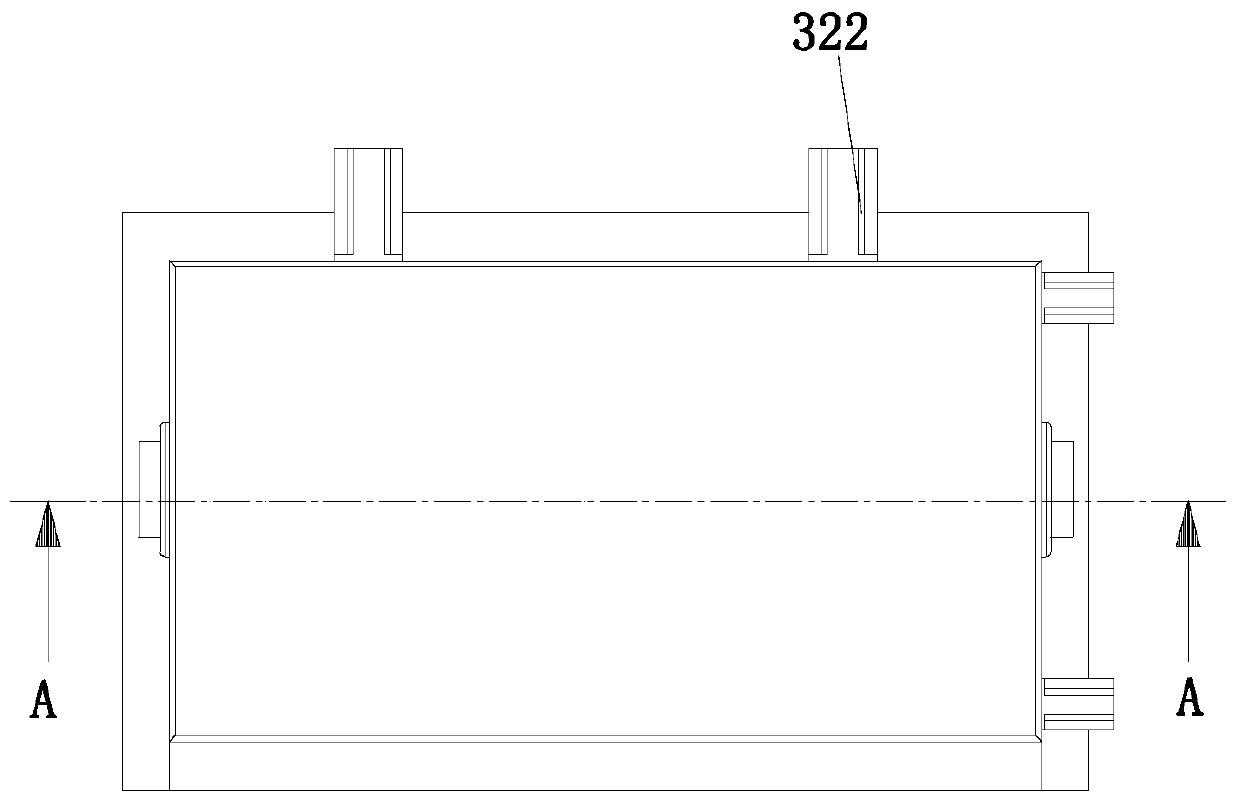

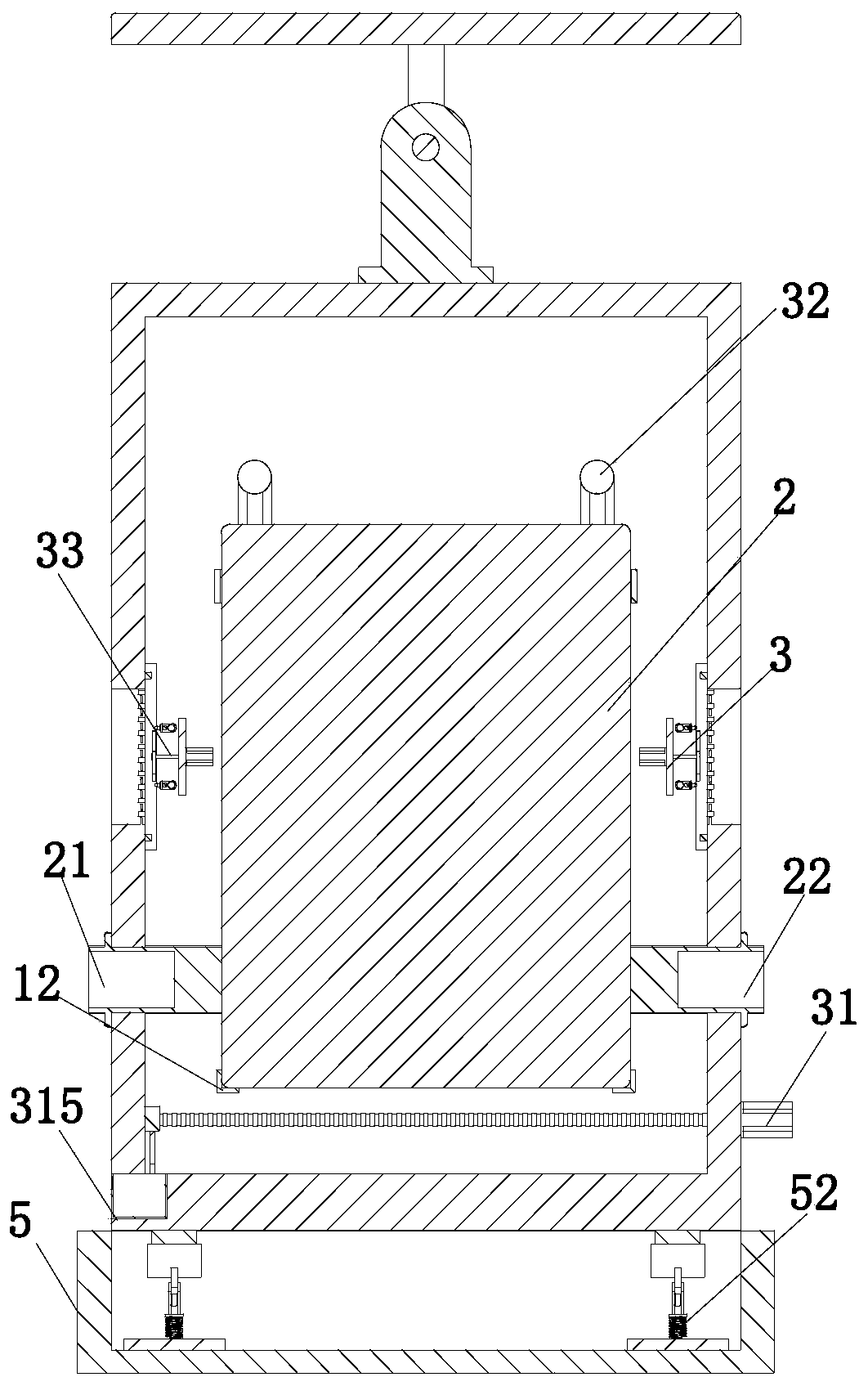

[0037] Below, combined with Figure 1 to Figure 11 And specific embodiment, the present invention is described further:

[0038] An automatic dust removal and shock absorption process for a refrigerator, comprising the following steps:

[0039] Step 1. Solar panels provide electric energy refrigeration: including a refrigeration box 1, a refrigerator body 2, a dust removal assembly 3, a light receiving rotating assembly 4, and a shock absorption assembly 5. The refrigeration box 1 is vertically arranged, and the refrigeration box 1 Two ventilation windows 11 are arranged on the side walls on both sides, and the two ends of the refrigerator body 2 are respectively provided with an inlet pipe 21 and an outlet pipe 22 extending to the outside of the refrigeration box 1, and the inside of the refrigerator box 1 is provided with two The installation frame 12 is fixedly connected, the refrigerator body 2 is arranged on two installation frames 12, the light receiving rotating assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com