Horizontal direct-connection type phase change heat exchange device

A phase-change heat and straight-through technology, which is applied to indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as blockage, large volume of phase-change heat devices, inconvenient transportation and loading and unloading, etc., to achieve good heat exchange effect, The effect of reducing the construction period and facilitating transportation and loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

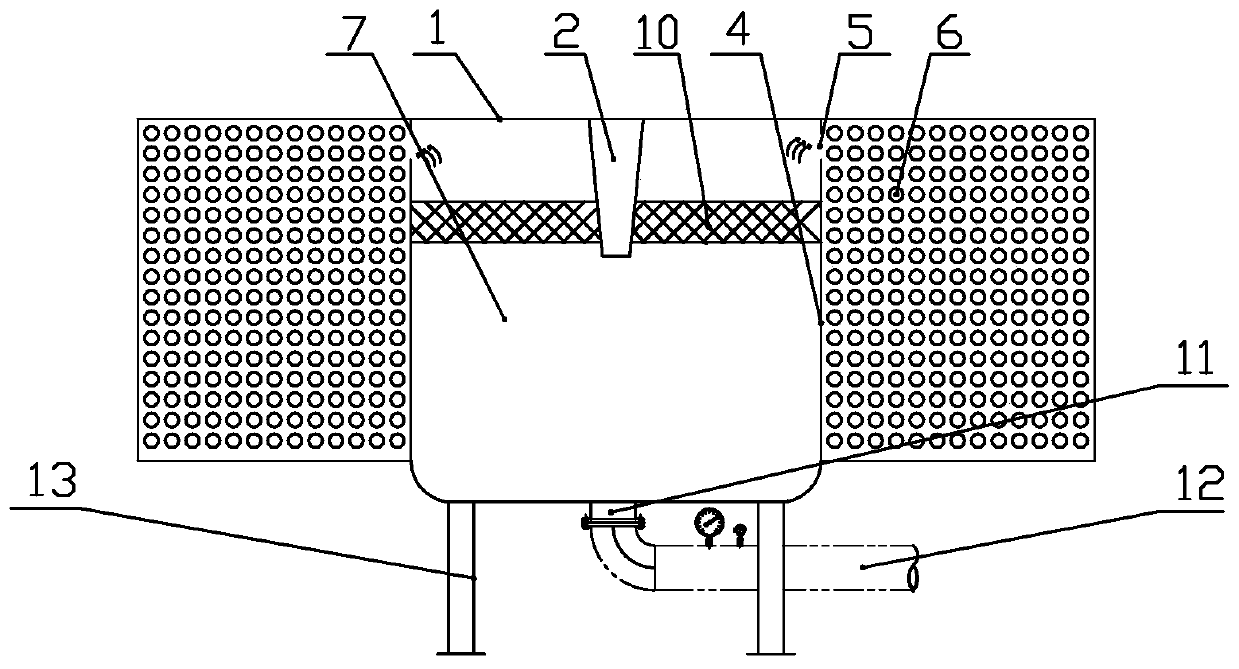

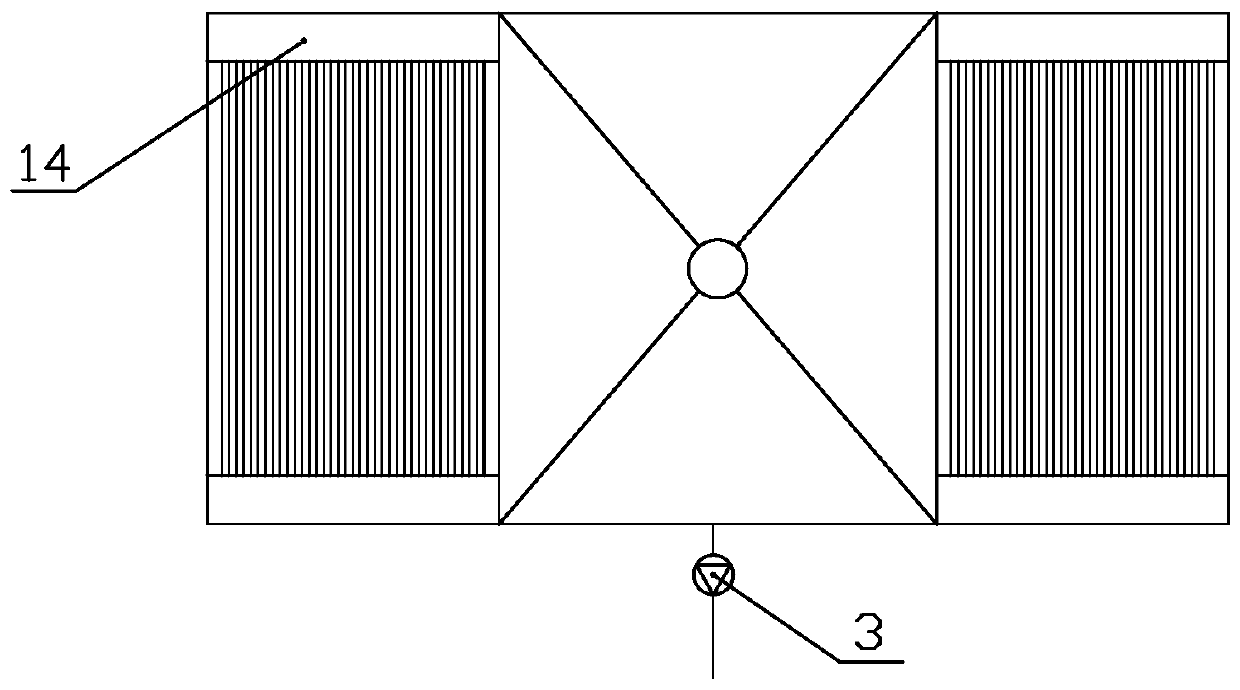

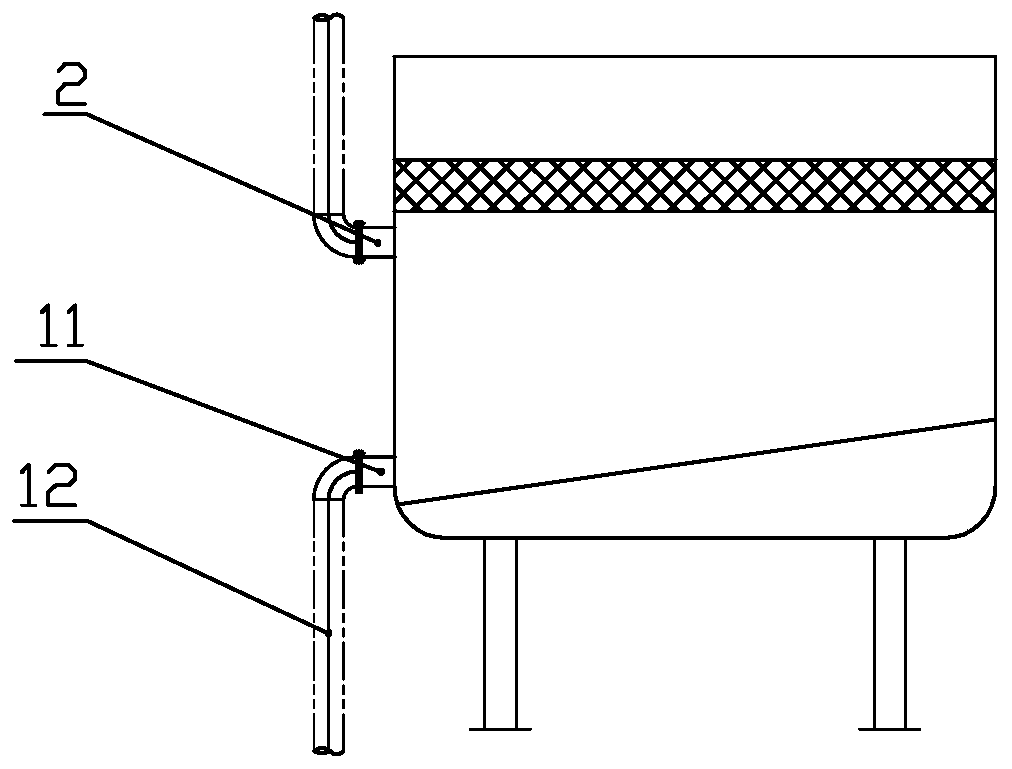

[0029] Specific implementation mode one: combine Figure 1-7 Describe this embodiment, a horizontal through-type phase-change heat device, which includes N horizontal through-type phase-change heat units, where N≥1, and each horizontal through-type phase-change heat unit includes a shell (1) and the nozzle (2), the housing (1) is a sealed structure, and the housing (1) is communicated with a vacuum pump (3), and the housing (1) is evacuated by the vacuum pump (3), At least one baffle (4) is fixed vertically inside the casing (1), and the inside of the casing (1) is divided into at least two cavities by at least one baffle (4). The upper part of the baffle (4) is provided with The steam channel (5), the nozzle pipe (2) communicates with a cavity, and heat exchange tube bundles (6) are respectively arranged in the remaining cavities, and the vacuum pump (3) and heat exchange tube bundle (6) The role of the flash chamber (7) is formed, and the remaining cavities form the heat ex...

specific Embodiment approach 2

[0054] Specific implementation mode two: as Figure 1-7 As shown, the heat exchange tube bundle (6) includes at least one layer of heat exchange tubes arranged in parallel up and down, and each layer of heat exchange tubes includes several straight heat exchange tubes parallel to each other along the horizontal direction.

specific Embodiment approach 3

[0055] Specific implementation mode three: as Figure 1-7 As shown, the heat exchange tube bundle (6) includes at least one layer of heat exchange tubes, and each layer of heat exchange tubes includes several coaxial and horizontally arranged heat exchange elbows sequentially from the inside to the outside. (Each heat exchange elbow has a rectangular ring structure. The situation of the heat exchange elbow is not shown in the figure.)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com