Experimental device of surrounding type local resonance light dot matrix sandwich plate structure

A technology of local resonance and experimental device, applied in measurement device, vibration suppression adjustment, spring/shock absorber functional characteristics, etc., can solve the problems of large stiffness and large mass, inability to control low-frequency elastic waves, etc., and achieve good load-bearing capacity , the effect of simple structure and easy-to-obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

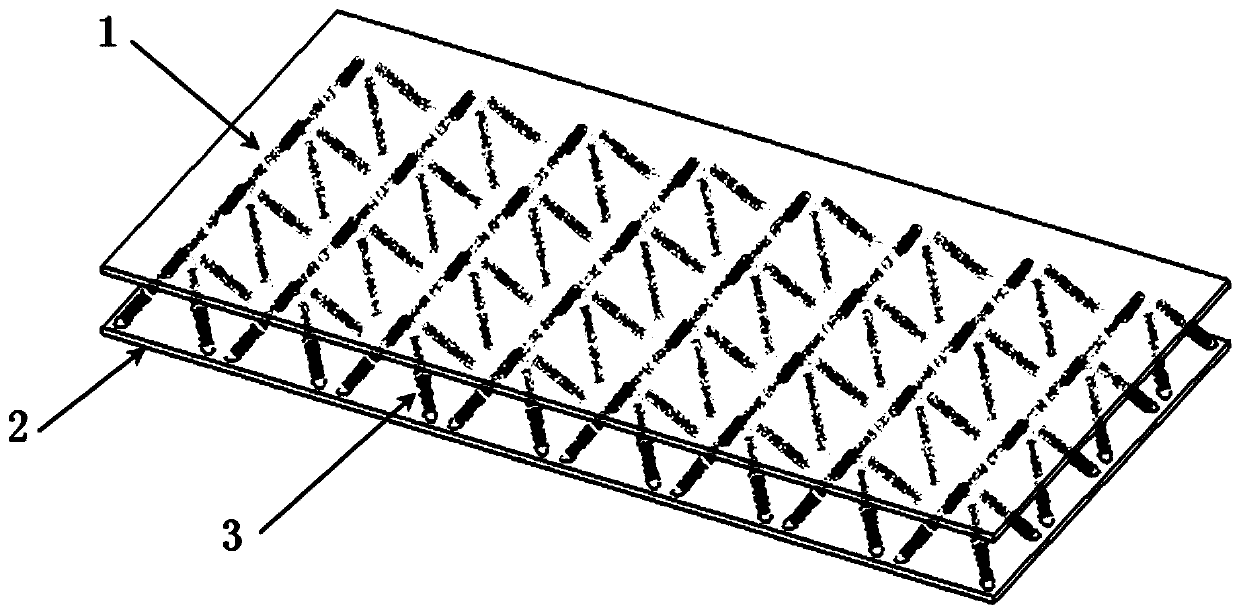

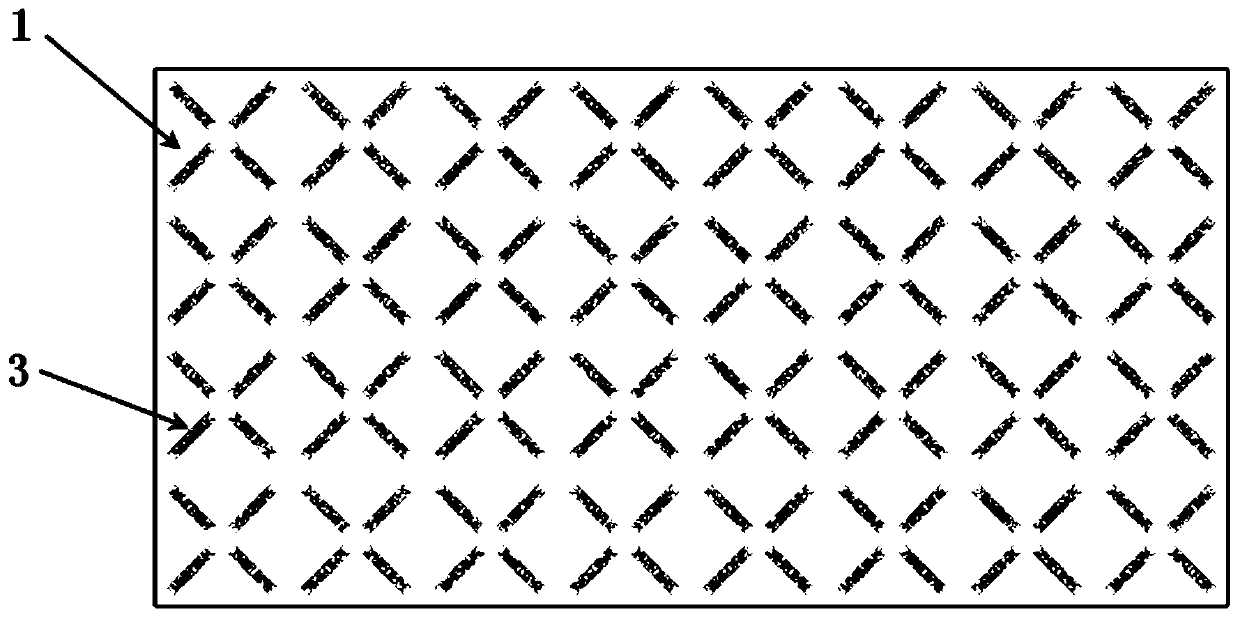

[0025] Specific implementation mode 1: Combination Figure 1 to Figure 9 Explaining this embodiment, the experimental device of a surrounding local resonance light-weight lattice sandwich panel structure described in this embodiment includes an upper plate body 1 and a lower plate body 2, and an upper plate body 1 and a lower plate body. 2 are arranged horizontally from top to bottom. The experimental device of the surround type local resonance light-weight lattice sandwich panel structure also includes a plurality of supporting units 3, which are arranged in a matrix on the upper plate Between the lower surface of the body 1 and the upper surface of the lower plate body 2.

[0026] The upper board body 1 and the lower board body 2 form a double-layer board structure, which has a more excellent load-bearing performance. The supporting unit 3 is connected with the upper and lower board bodies by bonding. The lower surface of the upper plate body 1 and the upper surface of the lowe...

specific Embodiment approach 2

[0027] Specific implementation manner two: combination Figure 1 to Figure 4 To describe this embodiment, the number of rows in the matrix formed by the multiple support units 3 is M, and the number of columns in the matrix formed by the multiple support units 3 is N, and both M and N are positive integers. The operator can select the number of support units 3 according to different experimental needs to achieve the best experimental effect.

[0028] The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination image 3 To describe this embodiment, each support unit 3 described in this embodiment is composed of four vibration absorber components, and the four vibration absorber components are arranged in a pyramid shape.

[0030] Other components are the same as those of the first or second embodiment in terms of connection relationship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com