Reaction chamber and etching method thereof

A reaction chamber and cavity technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of affecting the etching accuracy, slow gas flow rate, difficult etching effect, etc., so as to improve the etching effect and improve the uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

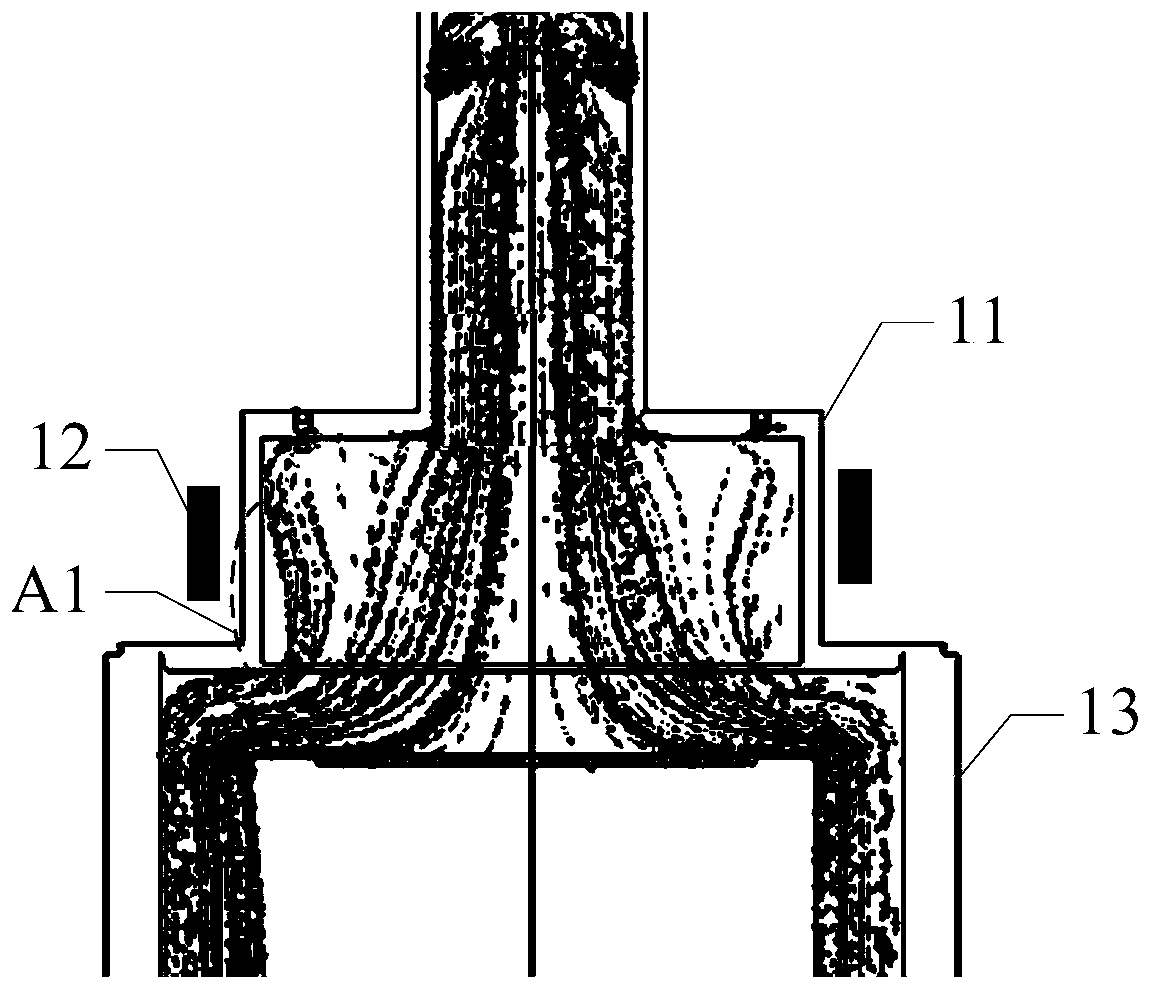

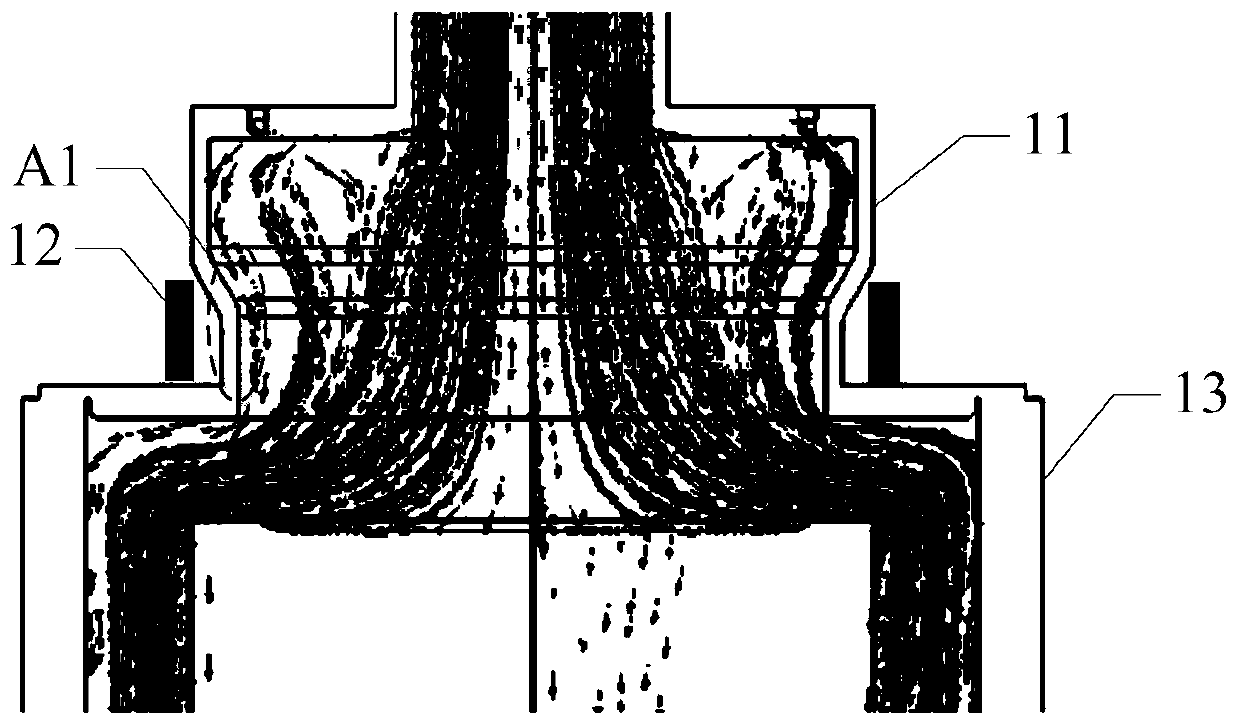

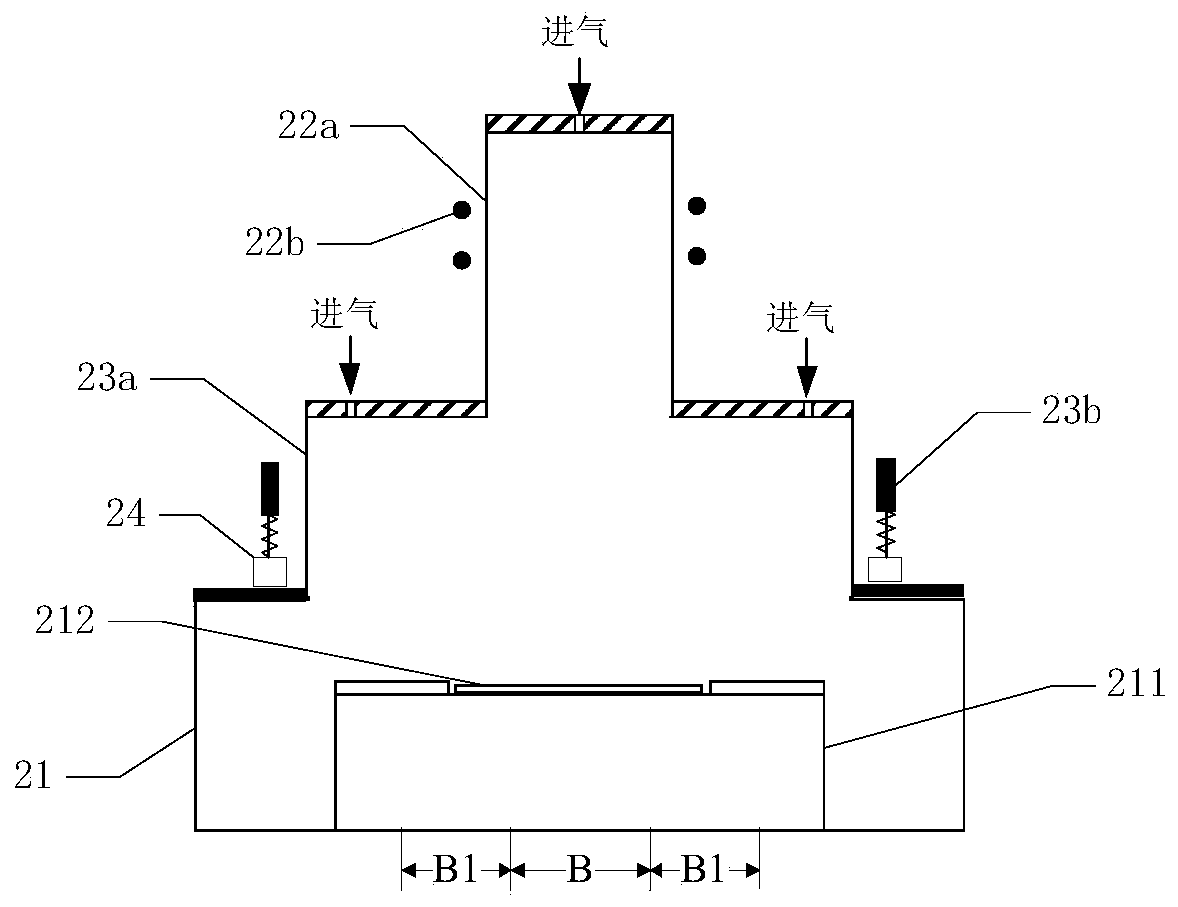

[0035] At present, in order to prevent the phenomenon of plasma extinction, the auxiliary cylinder can be set in a structure with a wide top and a narrow bottom. figure 2 It is a schematic diagram of the flow direction of reaction gas in another existing reaction chamber, such as figure 2 As shown, the size of the bottom of the auxiliary cylinder 11 is smaller than the size of the top of the auxiliary cylinder 11, the reaction gas at position A1 flows close to the side wall, the gas density is the same as that of other positions, and the gas flow rate is uniform. Between the deposition step and the etching step, Gas residue at the position A1 can be avoided, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com