Vehicle heater system

A technology for heaters and vehicles, applied in burners, heat exchanger types, indirect heat exchangers, etc., can solve the problems of carbon deposition, low combustion efficiency and power density of heaters, and achieve high combustion efficiency and reliability. Reliable effect of ignition and ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

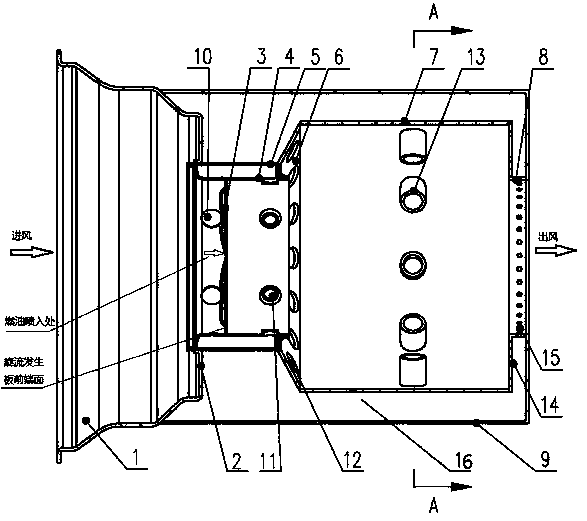

[0044] Such as figure 1 As shown, a premixed ignition and diffusion burner, the burner includes a burner outer cylinder, an air supply installation base, a premixed ignition chamber and a diffusion combustion chamber, the air supply installation base, a premixed ignition chamber and a diffusion chamber The burners are sequentially connected in series, and the premixed ignition chamber and the diffusion burner are arranged in the outer cylinder of the burner.

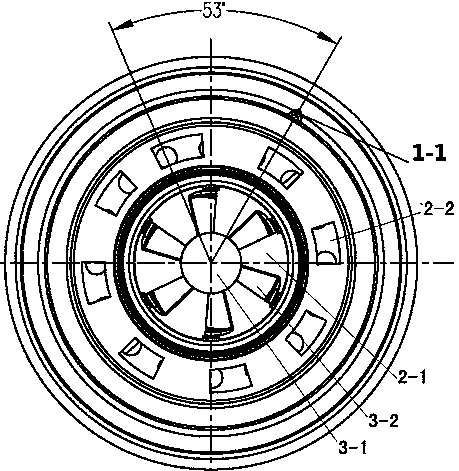

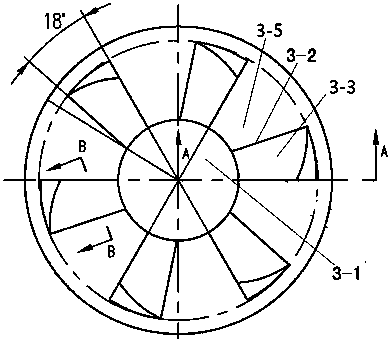

[0045] Preferably, the air supply installation base includes a mounting bracket 1 and a combustion air supply circular plate 2, the first end of the installation bracket 1 is open, and the second end is provided with a combustion air supply circular plate 2, and the combustion air supply circular plate 2 A central ventilation hole 2-1 is set in the center, and a circumferential vent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com