Flow field self-adaptive battery plate structure and fuel cell

A battery plate, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of difficulty in verifying flow field performance, complex flow field structure, and poor practicability. The effect of uniform distribution and improved distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

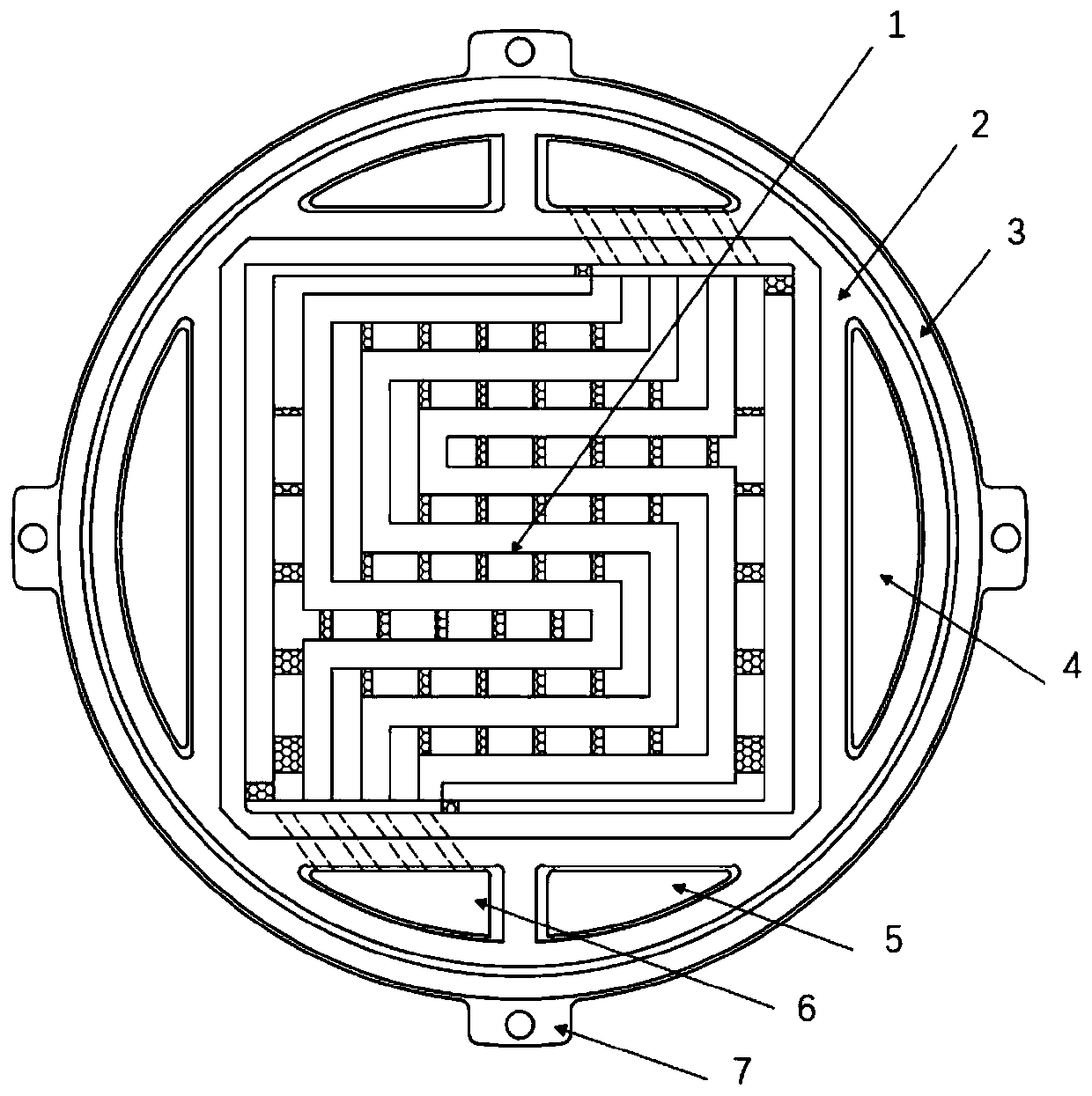

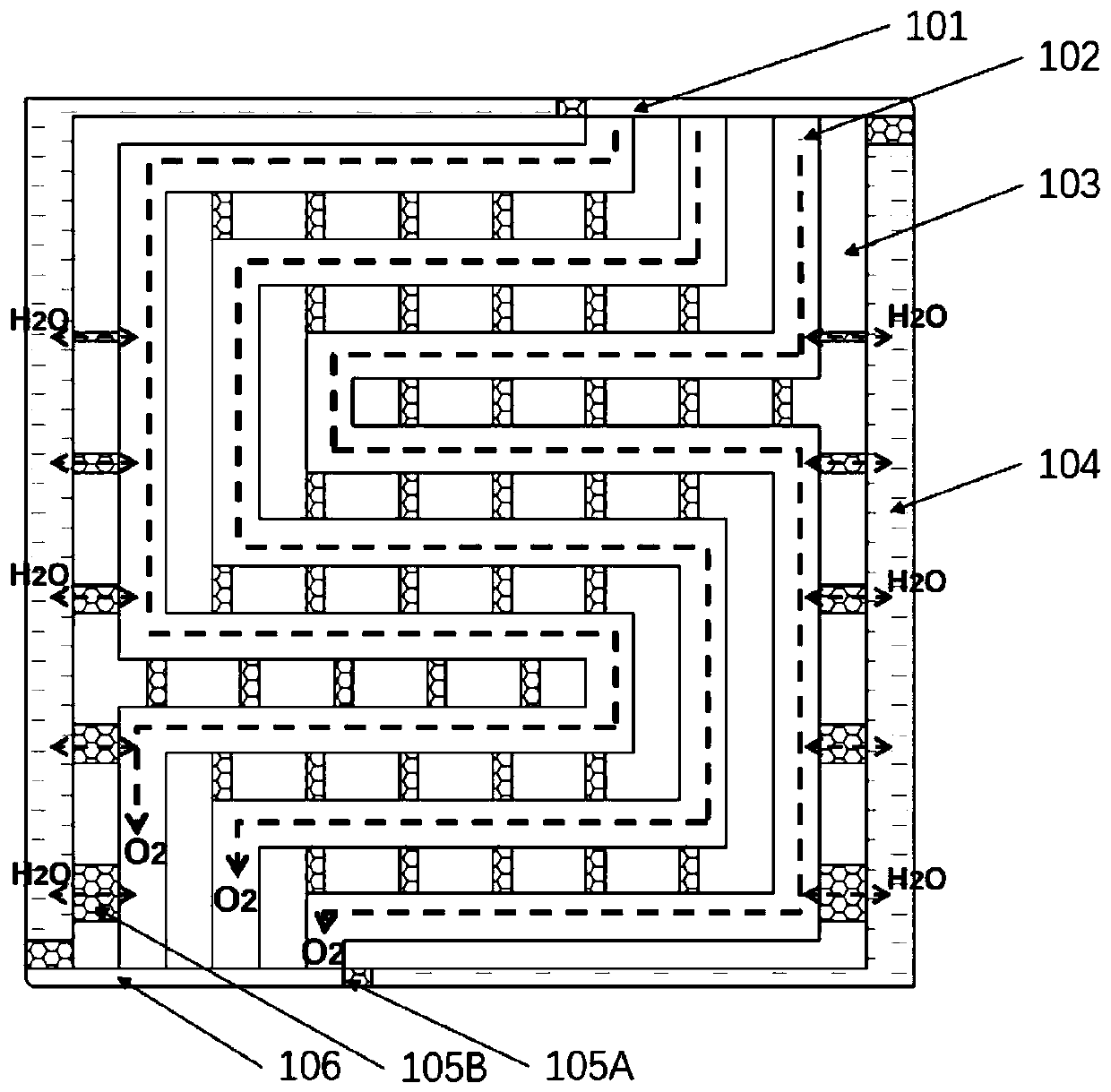

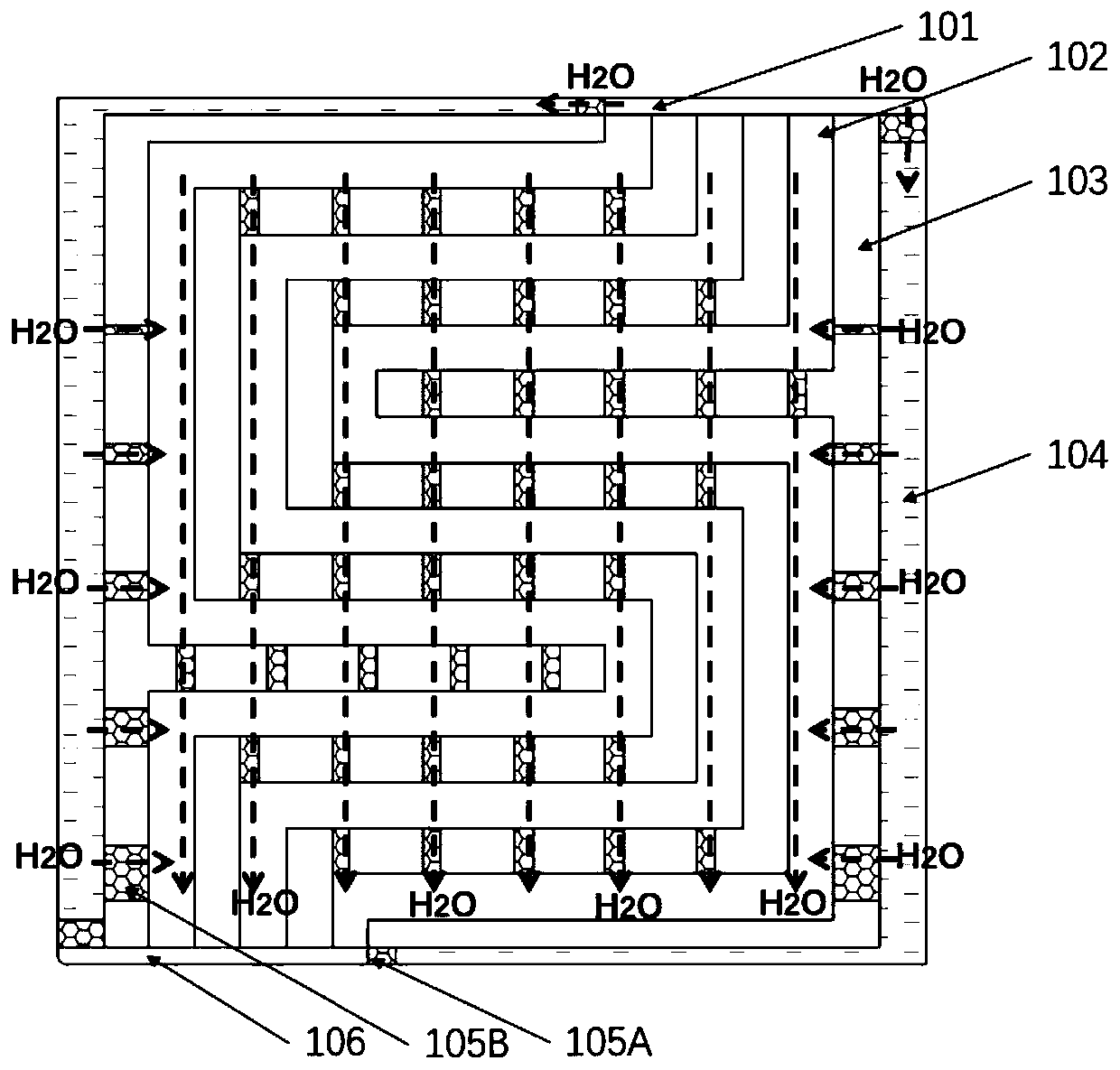

[0051] like Figure 1-5 As shown in the figure, an integrated regenerative fuel cell plate structure with adaptive flow field includes: a dual-function flow field 1, an inner sealing groove 2, an outer sealing groove 3, a coolant cavity port 4, a hydrogen cavity port 5, an oxygen cavity Port 6, positioning ear 7; dual-function flow field 1 includes: flow field inlet 101, meandering flow channel 102, flow field ridge 103, water distribution area 104, water-conducting and air-isolating structure 105, flow field outlet 106; meandering flow The channel 102 adopts a 3-channel serpentine flow channel.

[0052] The electrode plate structure of this embodiment is used as the oxygen electrode plate 8 of the integrated regenerative fuel cell, and is stacked and assembled with the bifunctional membrane electrode 9 and the hydrogen electrode plate 8' to form a single cell, which can work in two working modes of power generation and electrolysis.

[0053] In the power generation mode: the...

Embodiment 2

[0063] like Figure 3b , this embodiment is basically the same as Embodiment 1, the difference is that the water-conducting and air-insulating structure 105 is realized in another way: by machining grooves on the flow field ridge 103, and filling the water-conducting and air-insulating structures in the grooves material; this implementation reduces processing difficulties and enhances water retention. The width of the groove increases with the demand of water flux in different regions. The width is generally between 0.1mm and 1mm, and the depth of the groove is generally between 0.1mm and 0.5mm. The water-conducting and gas-barrier film can be prepared from Nafion ionomer.

Embodiment 3

[0065] This embodiment is basically the same as Embodiment 1, except that the meandering flow channel adopts a single-channel serpentine flow channel; thereby reducing the number of flow channels in the dual-function flow field and increasing the length of the flow channel; The gas barrier structure 105 and the water distribution area 104 play a more critical role; such an arrangement is more suitable for a small-area one-piece regenerative fuel cell plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com