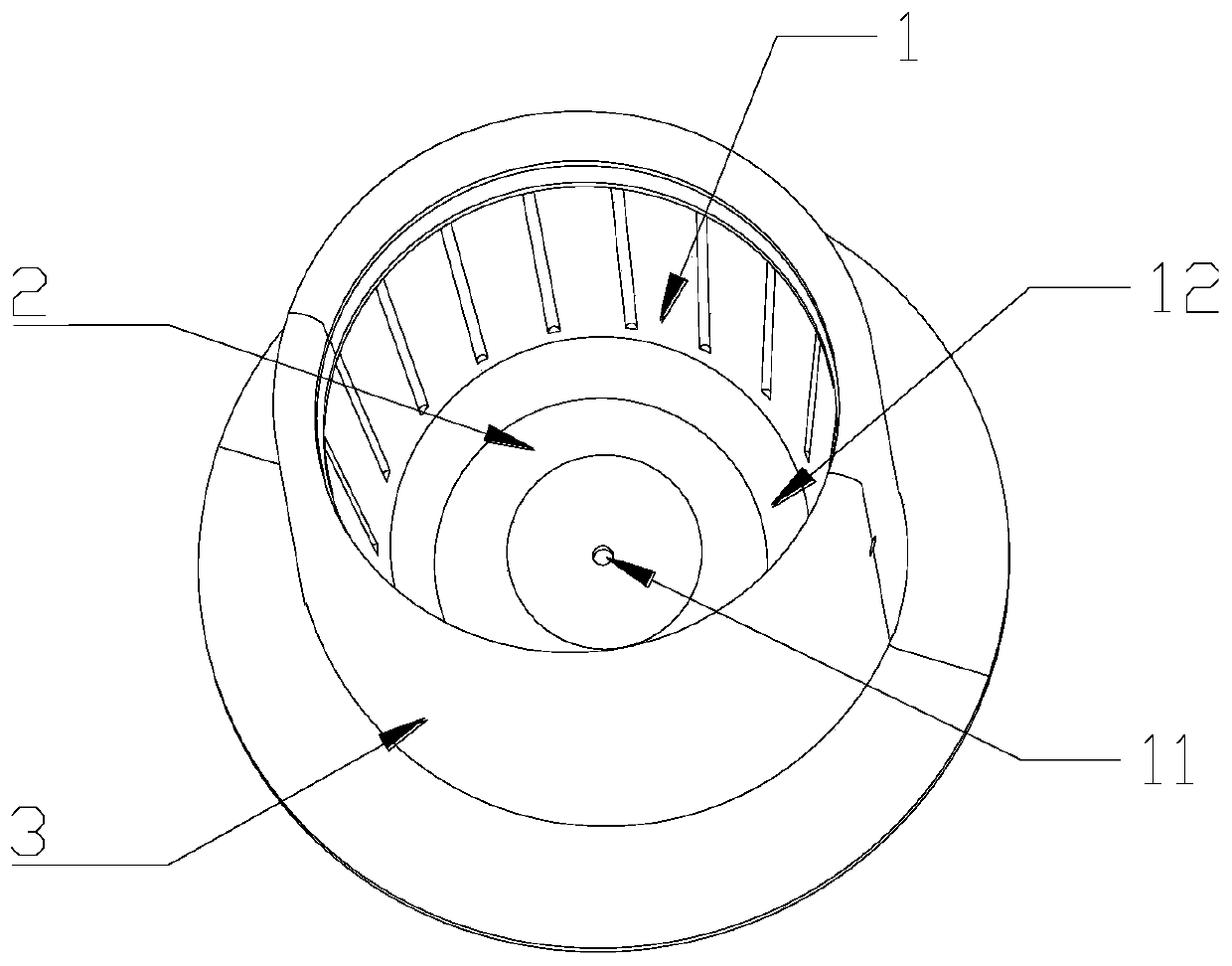

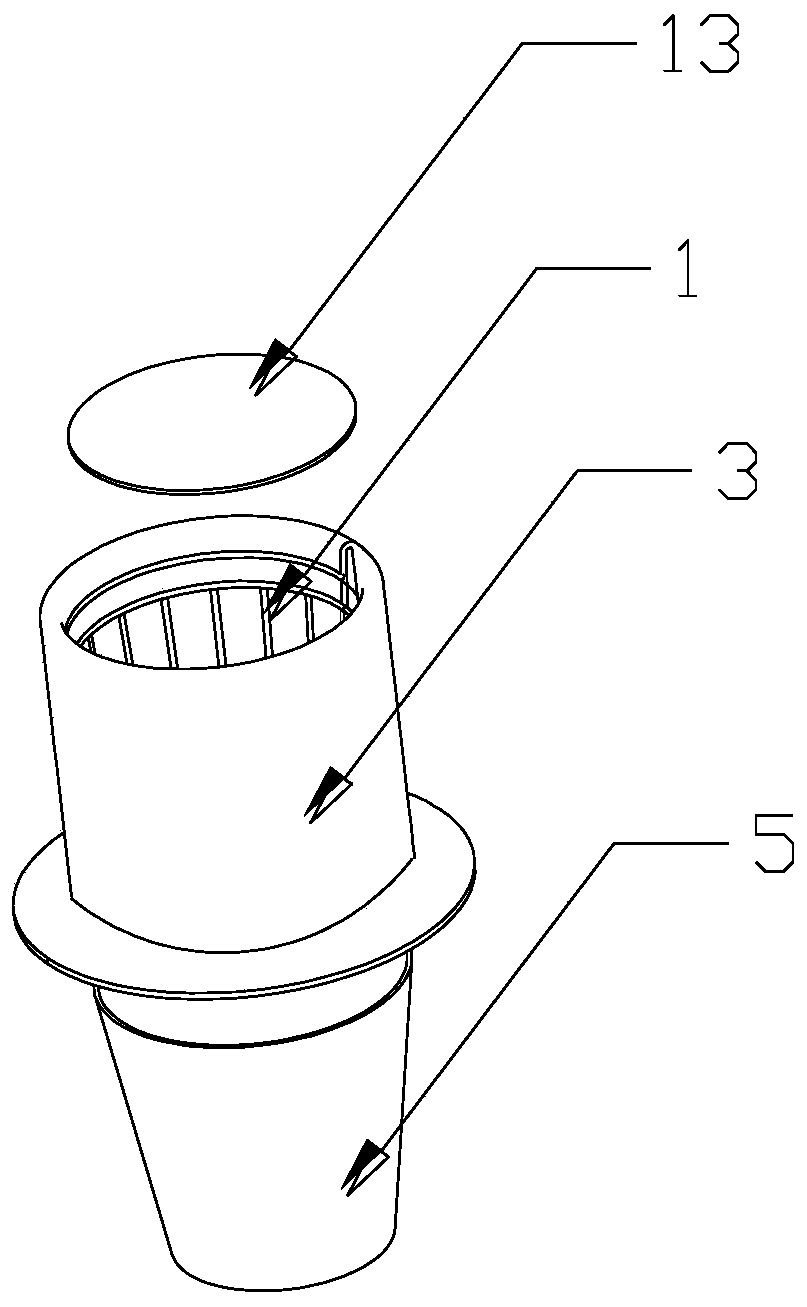

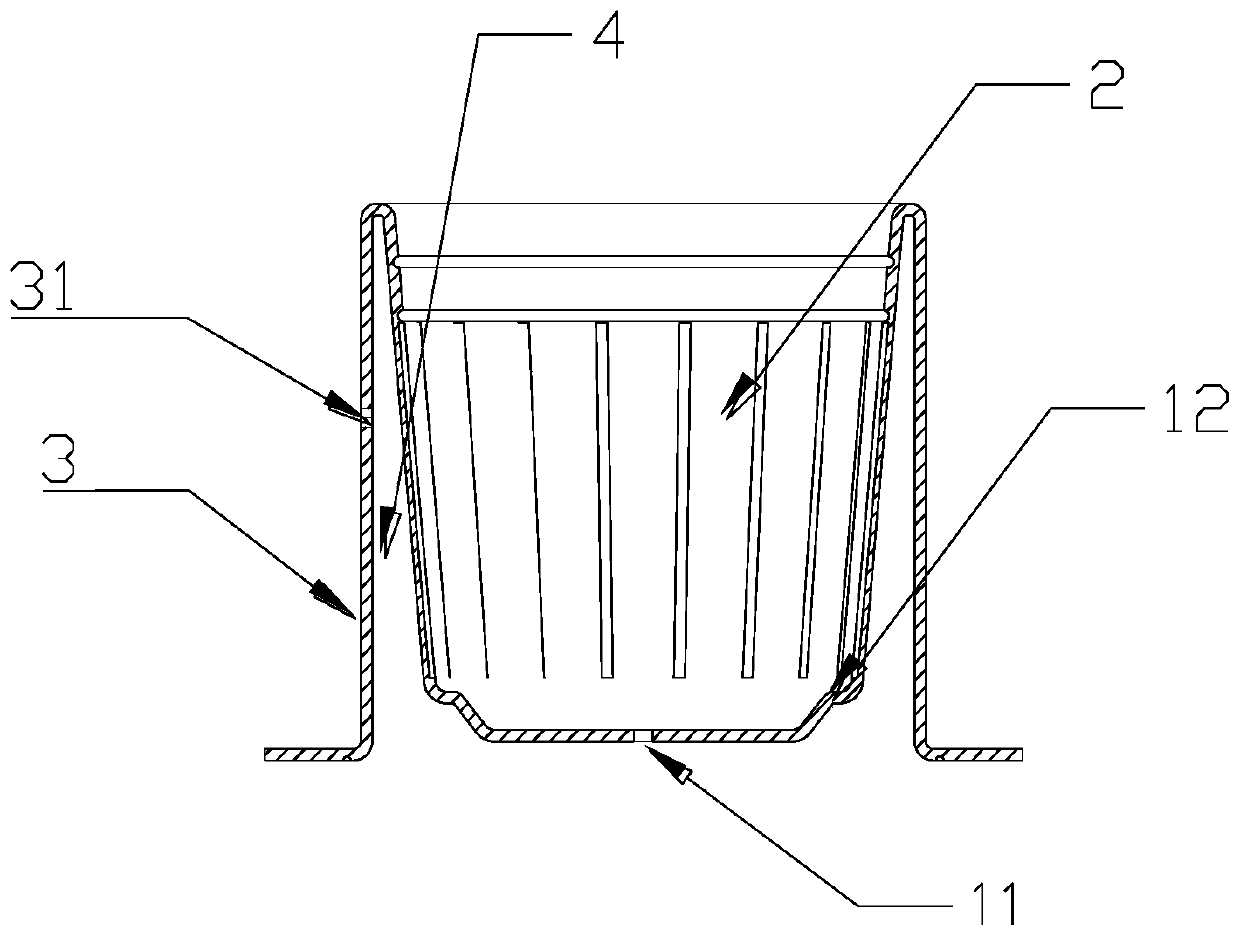

Coffee powder and coffee filter for trickling filtration and extraction of coffee powder

A technology of coffee powder and filter, which is applied in drip filter coffee cups and coffee powder field, which can solve the problem of poor taste, uneven taste of portable coffee brewing, lack of extraction time and dual coordination of drip filter effect, etc. problem, to achieve the effect of moderate thickness, proper dripping speed and pure fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0031] A. Colombian Rose Valley 8kg, the selected manor is Big Tree Manor, its growth altitude is 1700m, the variety is Caturra, and the treatment method is anaerobic double enzyme washing. Big Tree Manor is located in the Santander producing area of Colombia, on Big Tree Farm Only fully mature coffee cherries with bright red appearance are selected for picking, and the defective anaerobic fermentation is removed by washing with water, and then fermented with a special enzyme group. Excessively high temperatures are avoided during drying, and slow drying is adopted.

[0032] B. Ethiopian red cherries 2kg, produced in Sidamo, in Grade 1 classification, and grown at an altitude of 1850-2100m. After taking out the peel, the pectin part is removed by traditional fermentation. Depending on the climate, the treatment is about 36-48 time, dry on a drying rack for 10-12 days.

[0033] Then use the IDEA roasting machine to roast, the amount of green beans is 10kg, the temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com