Waste gas purification equipment based on waste incineration heat energy recovery

A heat energy recovery and exhaust gas purification technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of low recovery efficiency and low utilization rate of heat resources, achieve good results and improve waste heat recovery efficiency , the effect of enhanced liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

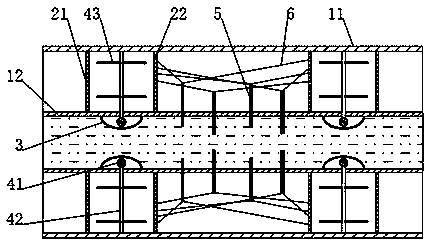

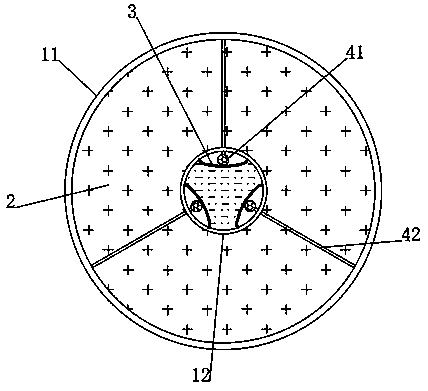

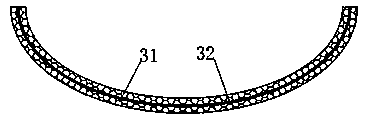

[0043] see Figure 1-2 , a waste gas purification device based on waste incineration heat energy recovery, comprising an outer purification gas pipe 11 and an inner heat absorption pipe 12, the inner heat absorption pipe 12 is located in the middle of the inner side of the outer purification gas pipe 11, the outer purification gas pipe 11 and the inner heat absorption pipe 12 are fixedly connected with multiple groups of filter air stacks, and multiple self-oscillating heat conducting rods 5 are arranged between adjacent filter air stacks. The heat-conducting rods 5 are evenly distributed in the lateral direction, so that the distances of the self-oscillating heat-conducting rods 5 inside the outer purification air pipe 11 are different, so that the heat from the exhaust gas transmitted from the swinging heat-conducting rods 5 can be dissipated in a wider range in the waste heat absorption liquid, so that The waste heat absorbing liquid has a better effect on heat absorption a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com