Pipe cutting device for water conservancy project

A water conservancy project and cutting device technology, applied in the direction of pipe shearing device, shearing device, positioning device, etc., can solve the problems of increasing project construction cost, reducing pipe material utilization rate, unfavorable operation efficiency, etc., to improve the quality of clamping , to ensure the cutting quality, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

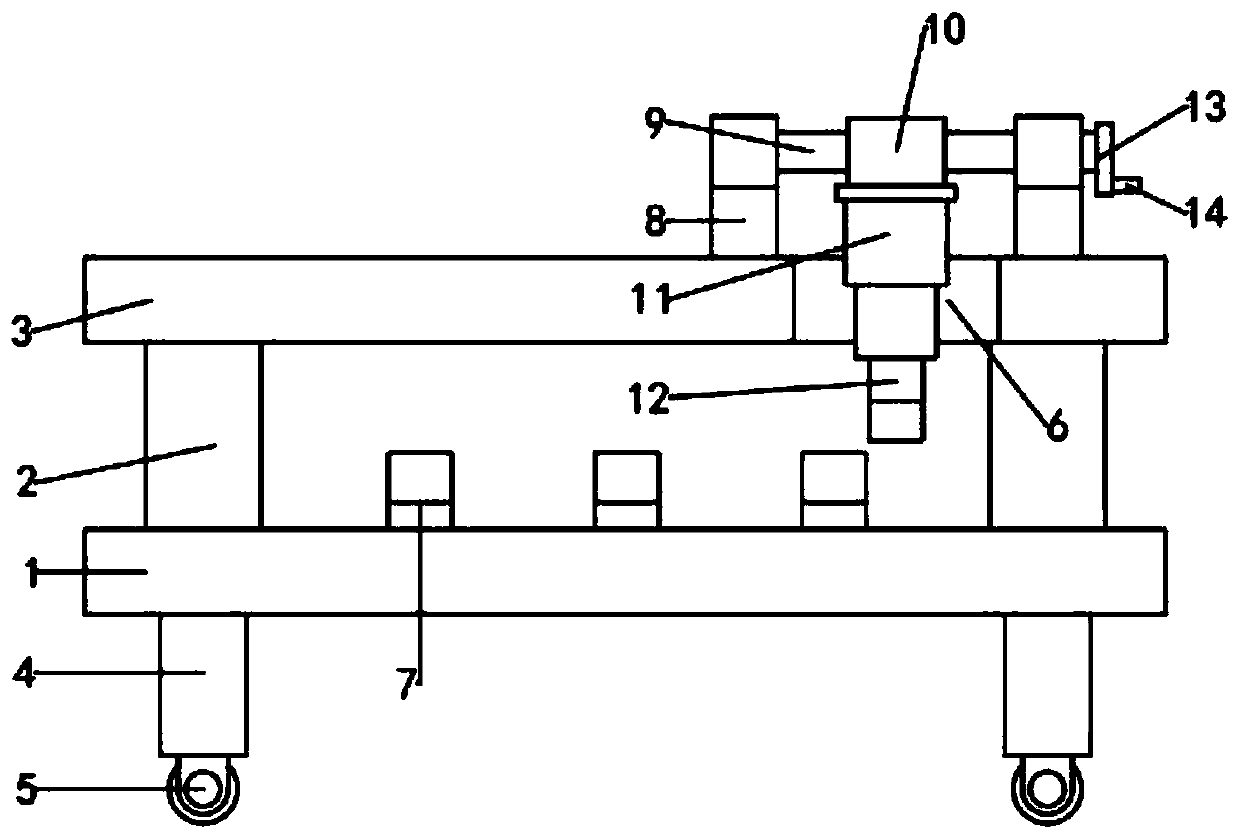

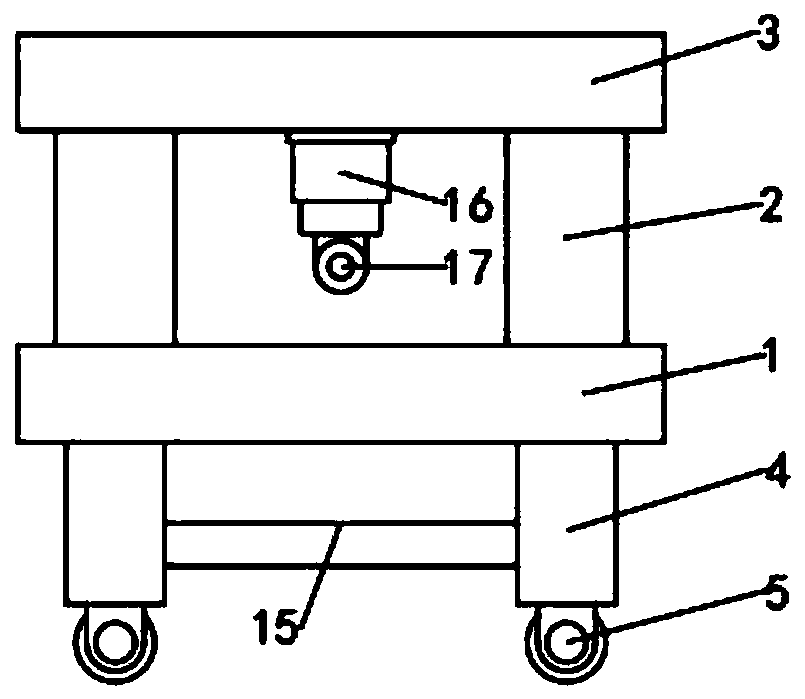

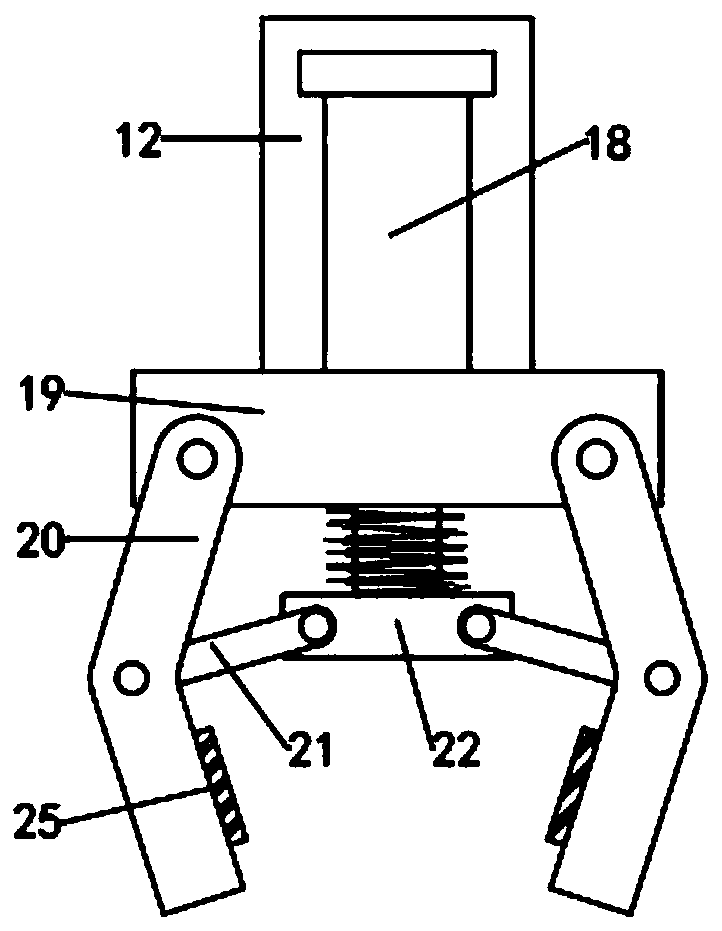

[0023] see Figure 1-6 , a pipe material cutting device for water conservancy projects, including a workbench 1, the lower end surface of the workbench 1 is fixedly connected with vertical support legs 4, the number of support legs 4 is four and arranged at four corners of a rectangle, The upper end surface of the workbench 1 is fixedly connected with a vertical support frame 2. The number of support frames 2 is four and arranged at four corners of a rectangle. The ends of the four support frames 2 facing away from the workbench 1 are connected to the mounting base 3 ; The workbench 1 is equidistantly equipped with a plurality of limit seats 7, the number of limit seats 7 is not less than three, the limit seats 7 are used to fix the pipe material to be cut, and the installation seat 3 is provided with an inlet The feeding mechanism includes an assembly seat 8, the assembly seat 8 is fixedly connected to the upper end surface of the installation seat 3, the number of the assemb...

Embodiment 2

[0032] In Embodiment 1, before the pipe material is cut, the stop block 24 and the clamping rod 20 have a fixed action on the pipe material. In order to ensure that the pipe material is not damaged during the fixing process, this embodiment uses Based on the improvement, the improvements are: the contact surfaces of the limit block 24 and the clamping rod 20 and the pipe material are uniformly provided with a protective layer 25 to prevent the surface of the pipe material from being damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com