Foldable enclosure device for ship air layer resistance reduction system and air layer resistance reduction ship

A technology of enclosure device and air layer, which is applied in the direction of ship hull, hull design, ship construction, etc., can solve the problem of large ship bottom reconstruction and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

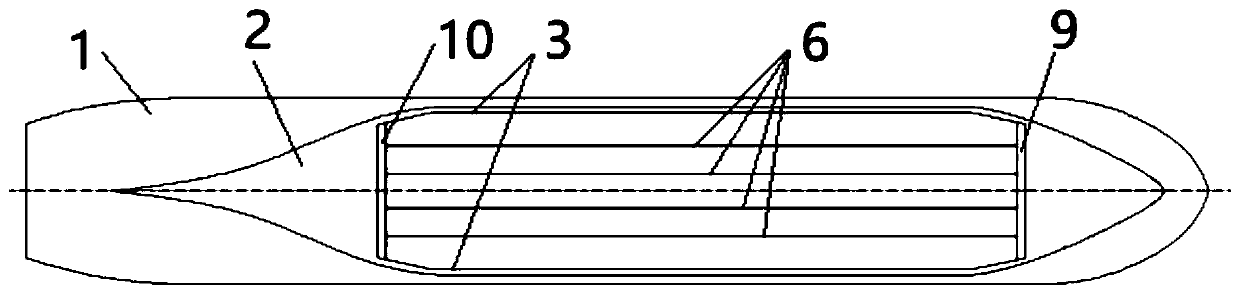

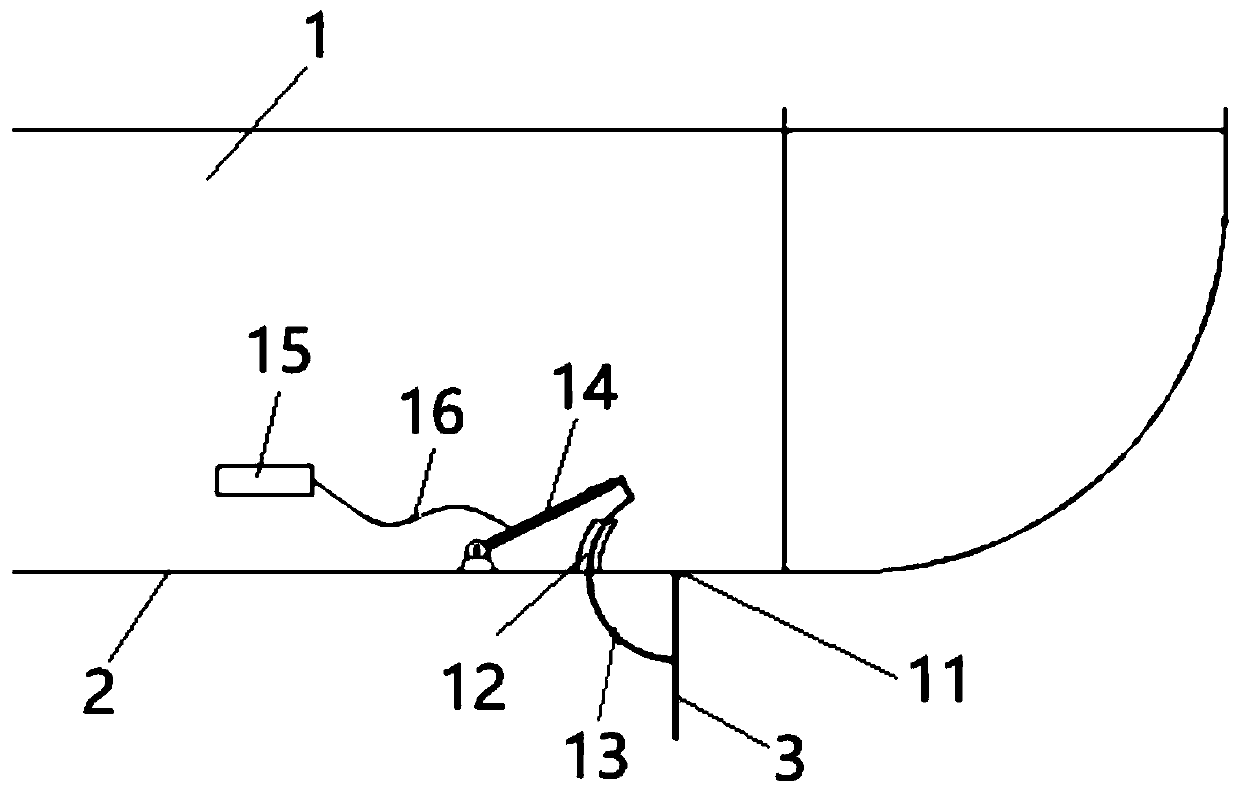

[0053] see Figure 1 to Figure 8 , the present embodiment provides a foldable enclosure device for the air layer drag reduction system of the ship, which is installed on the flat bottom 2 of the air layer drag reduction ship, and the top of the flat bottom 2 is the bilge. A foldable shroud device used for a ship air layer drag reduction system includes a plurality of cavitation shrouds and a plurality of driving structures. Each air pocket coaming is rotatably connected to the lower surface of the flat bottom 2 of the ship. After each air pocket coaming is rotated and unfolded, it cooperates to form an air cavity for accommodating the air layer of the air layer drag reduction ship. Each cavitation coaming is equipped with one or more driving structures respectively. The driving structure includes a driving part and a transmission part. The driving part is arranged in the bilge tank. The coaming is connected, and a sealing structure is provided between the transmission part an...

Embodiment 2

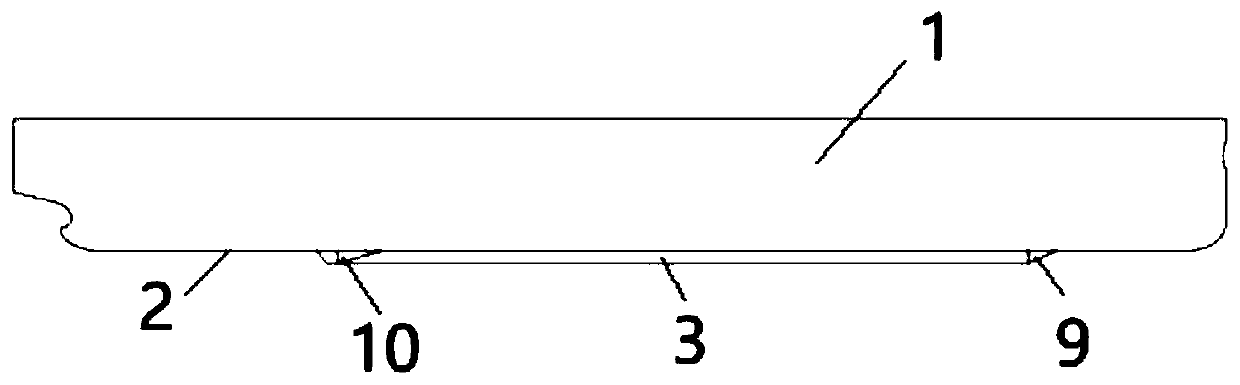

[0074] Please see figure 2 , Figure 5 to Figure 8 , On the basis of Embodiment 1, this embodiment is provided with a bow wedge block 9 and a stern wedge block 10 .

[0075] Both the bow coaming 4 and the transom 5 have a first side connected to the flat 2 and a second side corresponding to the first side.

[0076]The bow flexible part 7 is arranged on the stern side of the bow coaming, and the bow flexible part 7 is respectively connected with the flat bottom 2 and the second side of the bow coaming 4. In the unfolded state, the bow flexible part 7, the bow The coaming 4 and the ship's flat bottom 2 cooperate to form a first triangular structure, and the first triangular area is the bow wedge 8; The distance between the flat bottom 2.

[0077] The stern side of the stern coaming is provided with a stern flexible part 8 which is respectively connected to the second side of the flat bottom 2 and the stern coaming 5. In the unfolded state, the stern flexible part 8, the ster...

Embodiment 3

[0083] Please see figure 1 , image 3 and Figure 4 , On the basis of Embodiment 1 or Embodiment 2, a plurality of air cavity partitions 6 are arranged in the air cavity, that is, the air cavity coamings are all located between two ship side coamings 3 .

[0084] Each cavitation partition 6 is connected to the lower surface of the ship's flat bottom 2 in rotation along the ship's length direction, and divides the cavitation into a plurality of air cavities. Preferably, the plurality of air pocket separators 6 are symmetrical with respect to the center line of the bottom of the ship, and divide the air pocket into multiple air cavities on average.

[0085] Each cavitation barrier 6 is equipped with one or more drive structures as described in Embodiment 1, respectively. The connection and the positional relation of concrete cavitation partition 6 and driving structure, ship's flat bottom 2 are identical with the connection and positional relation of ship side coaming 3 and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com