Genuine leather product

A technology for genuine leather and products, applied in leather surface treatment, small raw leather/big raw leather/leather/fur treatment, leather/skin/leather/raw hide chemical treatment equipment, etc., which can solve the problems of damaged leather texture and touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

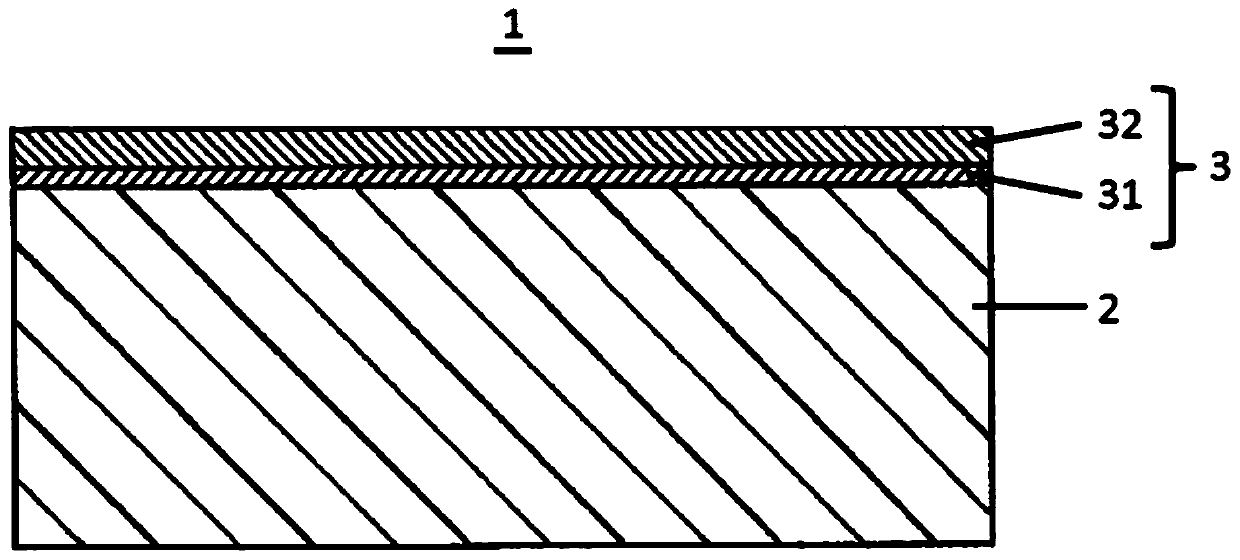

Image

Examples

Embodiment 1

[0108] (1) Preparation of leather substrate

[0109] Using adult cowhide as the raw hide, the leather is obtained through normal processes such as chrome tanning, followed by veneer drying. In addition, dyeing|staining was performed so that it may become the same color as the undercoat layer mentioned later.

[0110] (2) Formation of undercoat

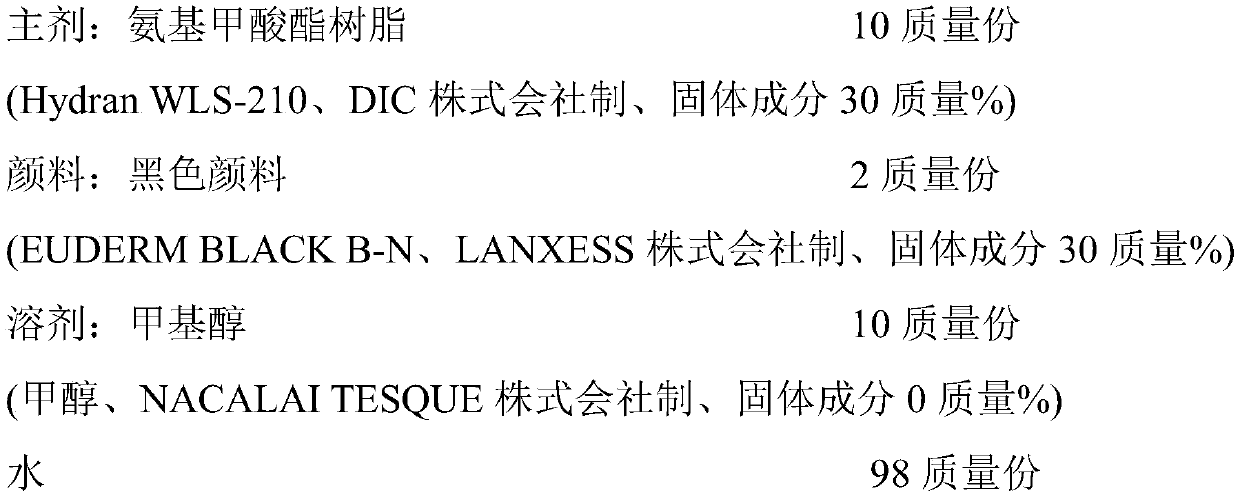

[0111] [Recipe A1]

[0112]

[0113] Preparation

[0114] According to formula A1, mix each raw material with a mixer. The viscosity was 12 seconds (cup viscometer, viscosity cup NK-2, manufactured by Anest Iwata Co., Ltd.).

[0115] With the resin composition for undercoat prepared according to above-mentioned formula A1, be 80g / m with the wet coating amount with spraying machine (trade name " TUROT.3400 / 1.41 ", BARNINI Srl make) 2 The method is coated on the surface of the leather substrate prepared according to the above (1), and treated with a dryer at 110° C. for 3 minutes to form a primer layer. The undercoat layer has...

Embodiment 2

[0126] Except not performing the formation of the undercoat layer of said (2), it carried out similarly to Example 1, and obtained the genuine leather product of Example 2. The thickness of the finishing layer was 7 μm. In the resulting leather product, although uneven color of the finishing layer was confirmed, pores and texture patterns were confirmed, and the appearance was good. In addition, MIU was 0.21, MIU / MMD was 26.6, and SMD×MMD was 0.0145, showing excellent touch and feel. In addition, the test piece after the abrasion test was excellent in abrasion resistance although a few cracks occurred in the finish layer and the grain surface (surface of the nipple layer).

Embodiment 3

[0128] The leather product of Example 3 was obtained in the same manner as in Example 1 except that the outermost layer of the above (4) was set to the following formulation B2. The thickness of the finishing layer is 8 μm. Pores and texture patterns were confirmed in the obtained genuine leather product, and the appearance was good. In addition, MIU was 0.21, MIU / MMD was 37.0, and SMD×MMD was 0.0117, and the texture was excellent, and the texture was excellent although a coating film feeling was felt. Furthermore, the appearance of the test piece after the abrasion test did not change, and the abrasion resistance was excellent.

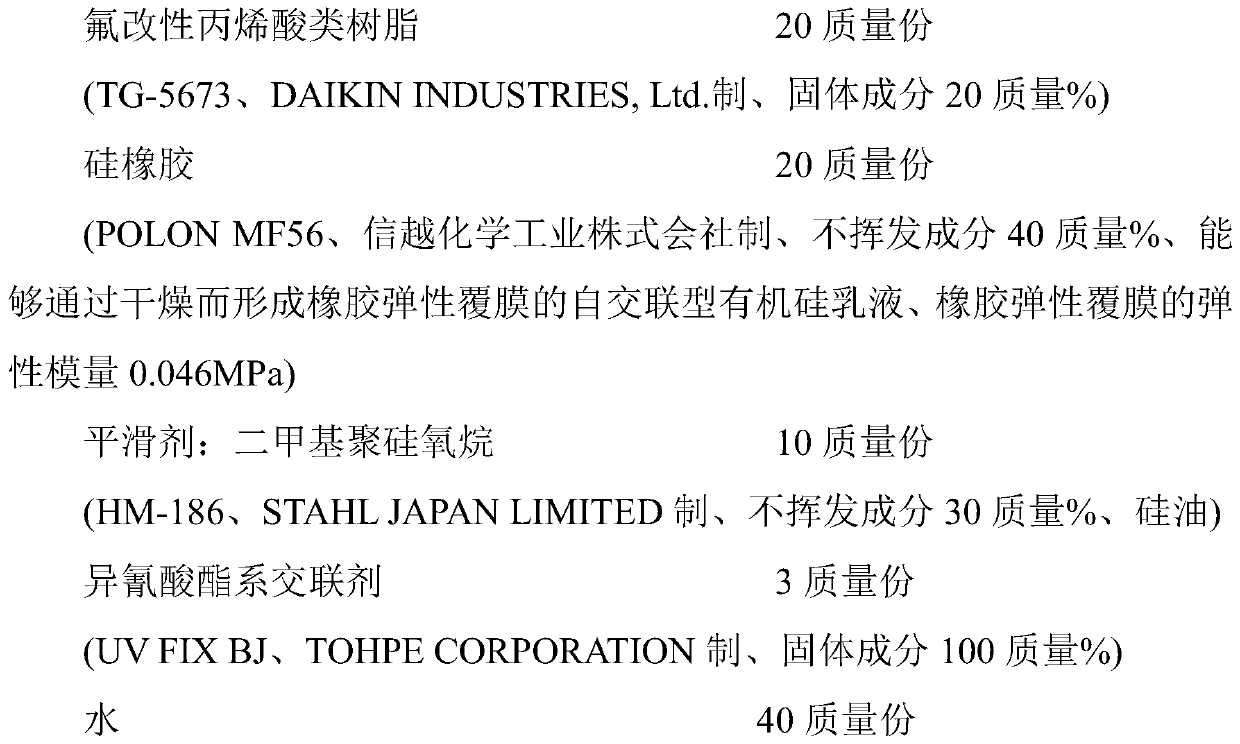

[0129] [Recipe B2]

[0130]

[0131]

[0132] Preparation

[0133] According to formula B2, after mixing all raw materials except the isocyanate-based crosslinking agent with a mixer, add the isocyanate-based crosslinking agent and mix with a mixer. At this time, the viscosity was 12 seconds (cup viscometer, viscosity cup NK-2, manufactur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap