Flange connection device for improving composite pipe structure stability

A technology of structural stability and connection device, which is applied in flange connection, pipeline connection arrangement, pipe/pipe joint/pipe fittings, etc., can solve the problems of easy crushing on the surface of the pipe and the effect of the pipe sealing effect, and achieves the protection of , the structure is simple, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

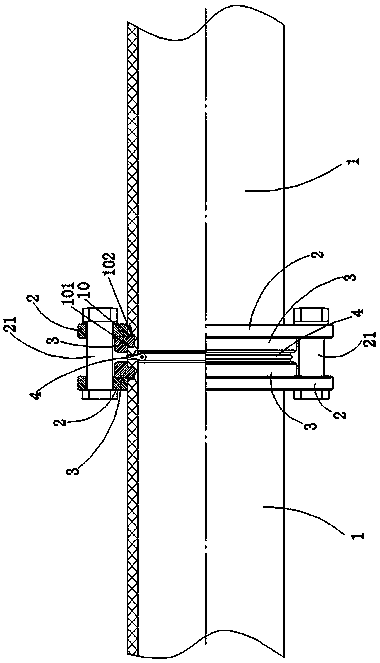

[0016] refer to figure 1 , a flange connection device that improves the structural stability of the composite pipe, and the connection device is used for the fixed connection of the ends of two composite pipes 1 . The connecting device comprises two flanges 2 , four connecting pieces 3 and one sealing piece 4 . The connecting piece 3 is preferably semi-circular, and the cross section of the connecting piece 3 is in the shape of a "7" or a shape of a "T". The end of each composite pipe 1 is preferably provided with two connecting pieces 3, and the two connecting pieces 3 are spliced to form a ring structure. The seal 4 is assembled on the connecting end faces of the two composite pipes 1, and the seal 4 adopts a rubber O-ring or an annular gasket. The connecting end of the composite pipe 1 is provided with an installation groove 10, the groove wall adjacent to the seal 4 of the installation groove 10 is the near groove wall 101, the groove wall away from the seal 4 is the f...

Embodiment approach 2

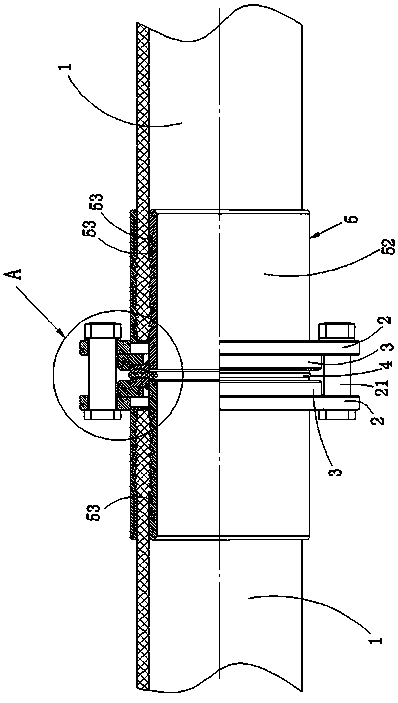

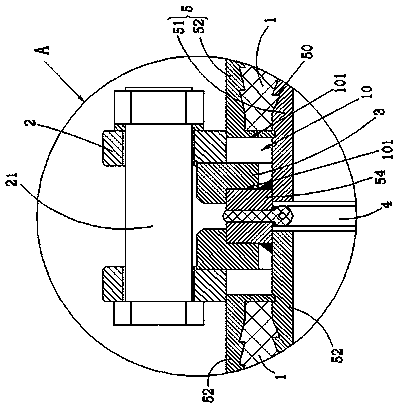

[0019] refer to figure 2 , image 3 The difference between this embodiment and Embodiment 1 is that in this embodiment, a connecting pipe 5 is fixedly arranged at each end of the composite pipe 1, and the connecting pipe 5 is preferably made of a material with high structural strength and is not easily corroded. become. refer to figure 2 , the connecting pipe 5 is integrally formed by connecting an inner pipe 51 and an outer pipe 52, the inner end of the inner pipe 51 is inserted into the composite pipe 1, the outer pipe 52 is sleeved on the outer wall of the composite pipe 1, and the inner pipe 51 The outer surface of the end is provided with a tooth groove 50, and the inner wall of the outer tube 52 is also provided with a tooth groove 50. Two rubber sealing rings 53 are arranged on the connecting surface of the composite pipe 1 and the outer pipe 52, and the external force is applied to make the composite pipe The plastic parts of the inner and outer surfaces of 1 sink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com