Multi-stirring-shaft vacuum microwave oven special for powder and heating method

A vacuum microwave oven and multi-stirring technology, which is applied to electric furnace heating, maintenance of heating chamber, lighting and heating equipment, etc., can solve the problem of single function of high temperature heating furnace, limited heating method of heat treatment environment or inconvenient change of heat treatment environment, and whether the heating is uniform or not. Affect product quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

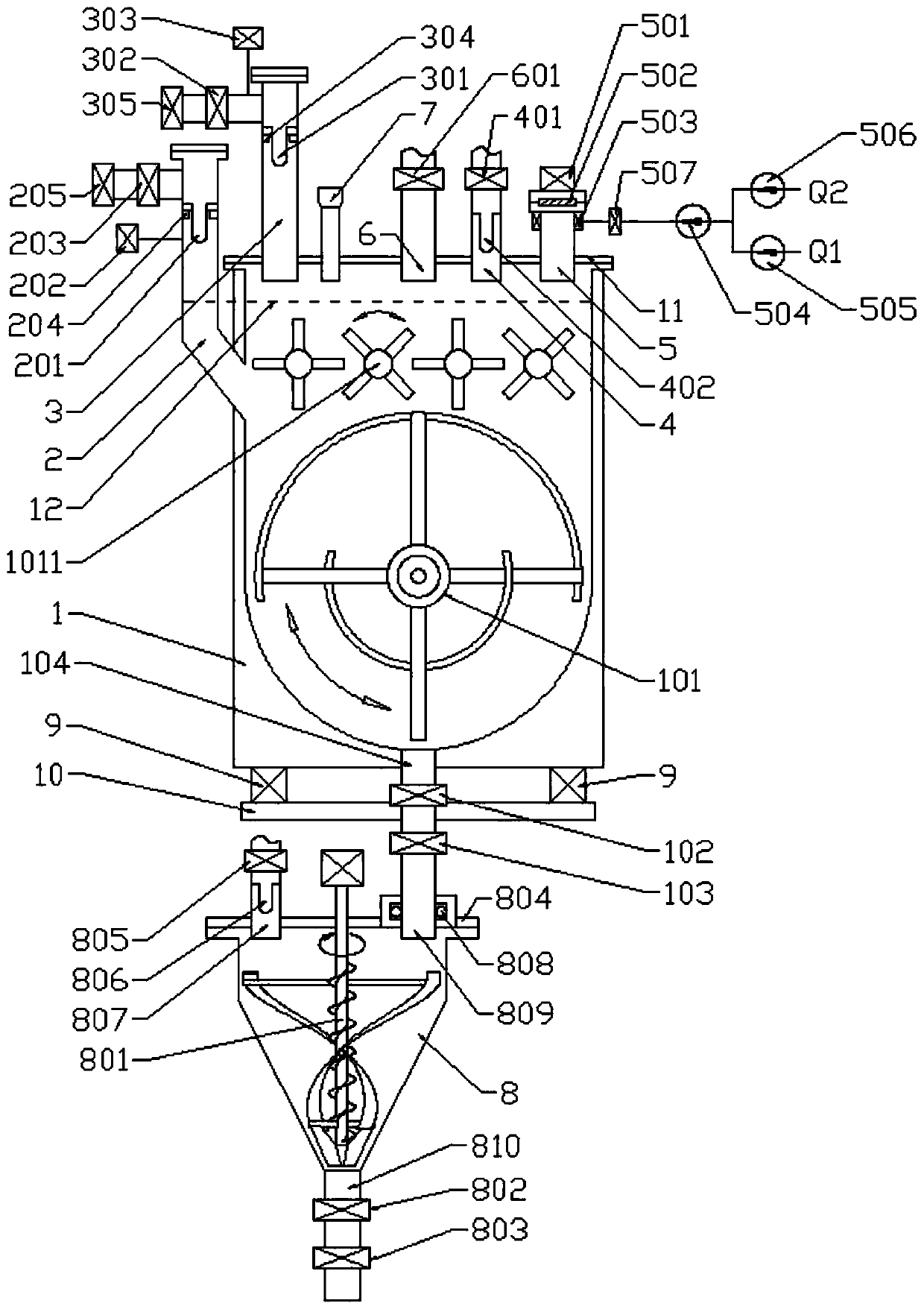

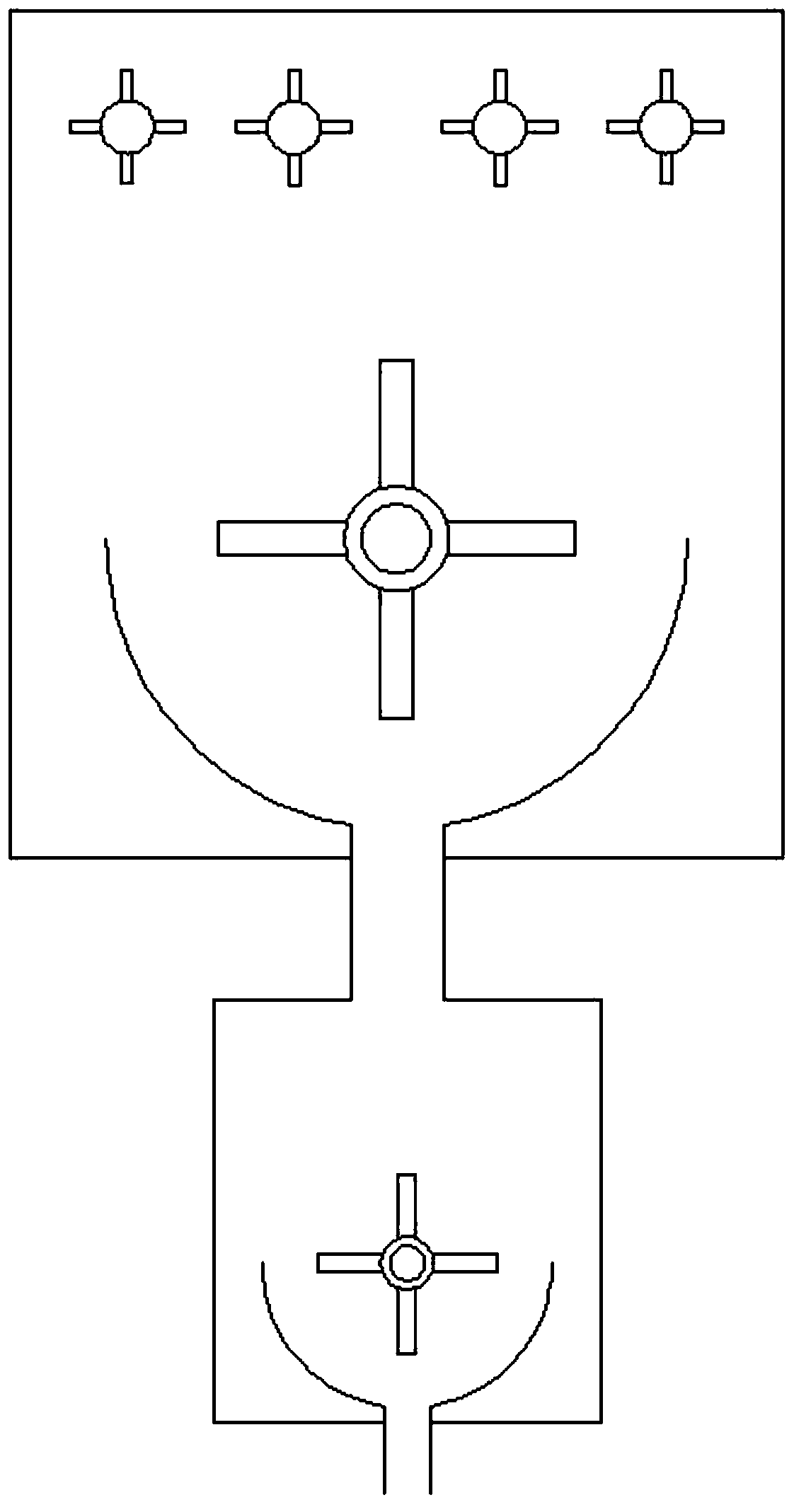

[0027] Such as figure 1 As shown, a vacuum microwave oven with multi-stirring shafts dedicated to powder includes a heating furnace body 1, a cooling furnace body 8, a load cell 9, and a lower vacuum channel 2 and an upper vacuum channel 2 arranged on the furnace cover 11 of the heating furnace body 1. Channel 3, exhaust channel 4, microwave input pipe 5, feed pipe 6, temperature measuring part 7, as shown in the figure, the heating furnace body 1 is a horizontal structure (that is, the stirring shaft is arranged horizontally), including the furnace body and Furnace cover 11, heating furnace body 1 The furnace body is a container welded by a U-shaped groove at the bottom and a rectangular flat plate, and a resistance heating element and an insulating layer are arranged in the shell on the outer side of the inner wall of the U-shaped groove that is in contact with the material. The outside is also provided with a forced cooling air duct (not shown in the figure); the bottom of ...

Embodiment 2

[0037] This embodiment still adopts the multifunctional horizontal vacuum microwave oven dedicated to the powder described in Embodiment 1. The difference is that the powder that undergoes heat treatment in this embodiment is a powder that needs to undergo redox reactions, such as putting iron oxide into the furnace at the same time Powder and carbon powder, the two can react under high-temperature atmospheric pressure environment, and the vacuum modules 205, 305 and their accessories do not need to work at this time. Similarly, the resistance heating element in the shell of the heating furnace body 1 can also be seen to be different. Disabled or traded off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com