Weighing material level control device of solid particle cooler

A solid particle, material level control technology, applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve the problem that the material level control system is not suitable, achieve good cooling control effect, control heat exchange The effect of residence time and accurate control of material level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

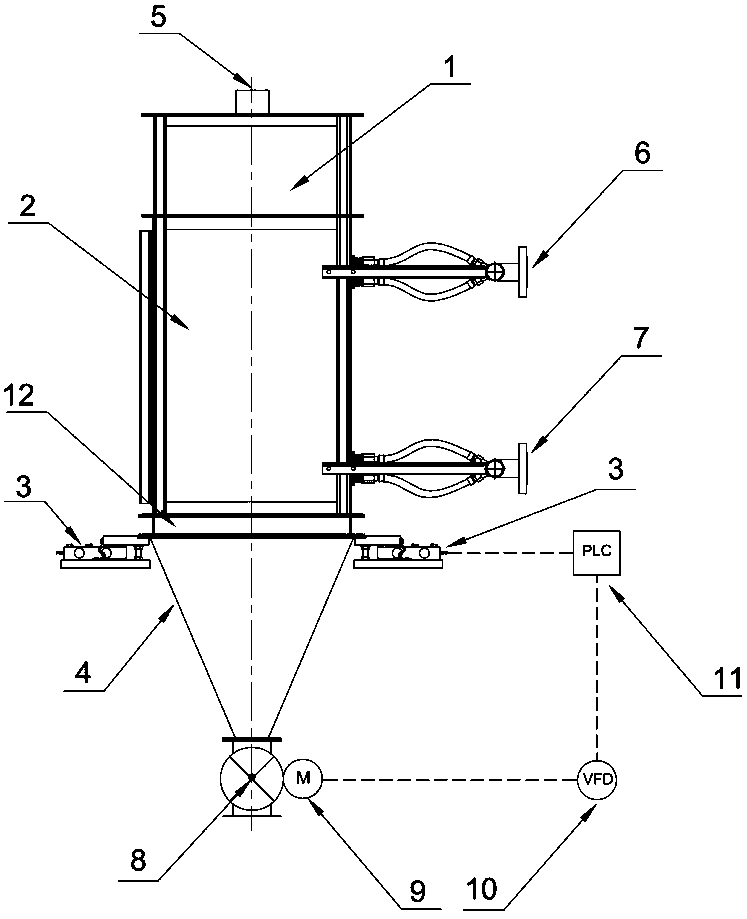

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

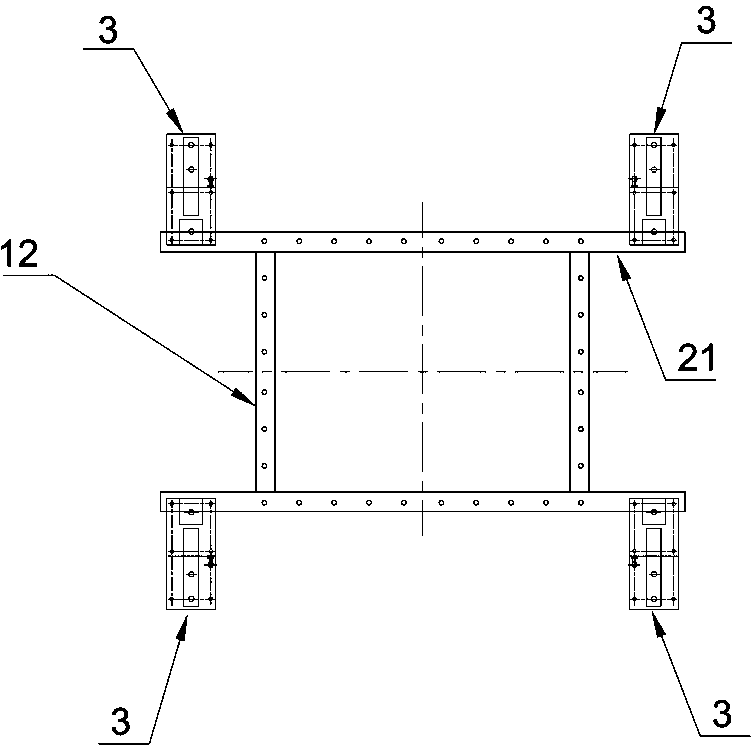

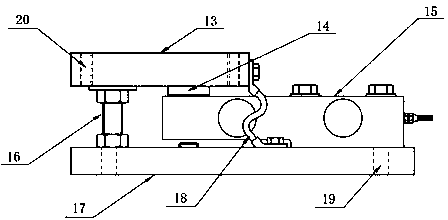

[0021] A weighing material level control device for a solid particle cooler, comprising a material level control bin 1, a cooling module 2, a load-bearing base 12, a weighing module 3, a discharging module 4, a feeding valve 8, a feeding valve motor 9, a frequency conversion device 10 and PLC control cabinet 11, the material level control bin 1 is a square empty bin, with a solid particle inlet 5 on the top, and heat exchange elements are distributed inside the cooling module 2, which is the main part for cooling solid particles, and the heat exchange element With water as the cooling medium, there are water inlet main pipe 7 and water outlet main pipe 6 on the outside of the cooling module 2, the load-bearing base 12 is welded at the bottom, and the weighing module 3 is fixed on the four legs 21 of the load-bearing base 12 by bolts. 3. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com