Stirring and uniformly-mixing device for paint powder

A technology of stirring and mixing powder, which is applied to mixers with rotating stirring devices, mixer accessories, mixers, etc., can solve the problems of uneven mixing, flying around, etc., and achieve the goal of improving quality and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

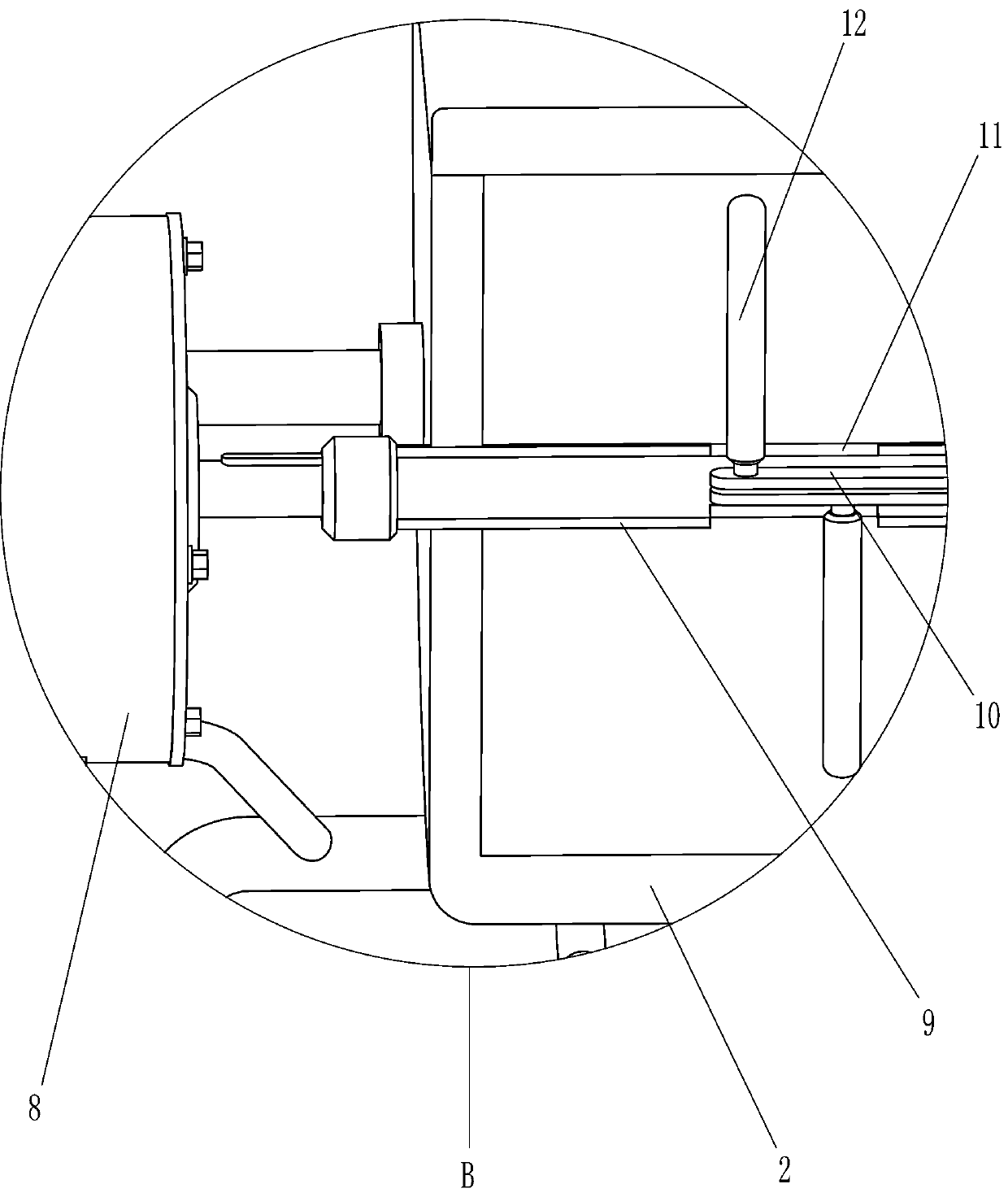

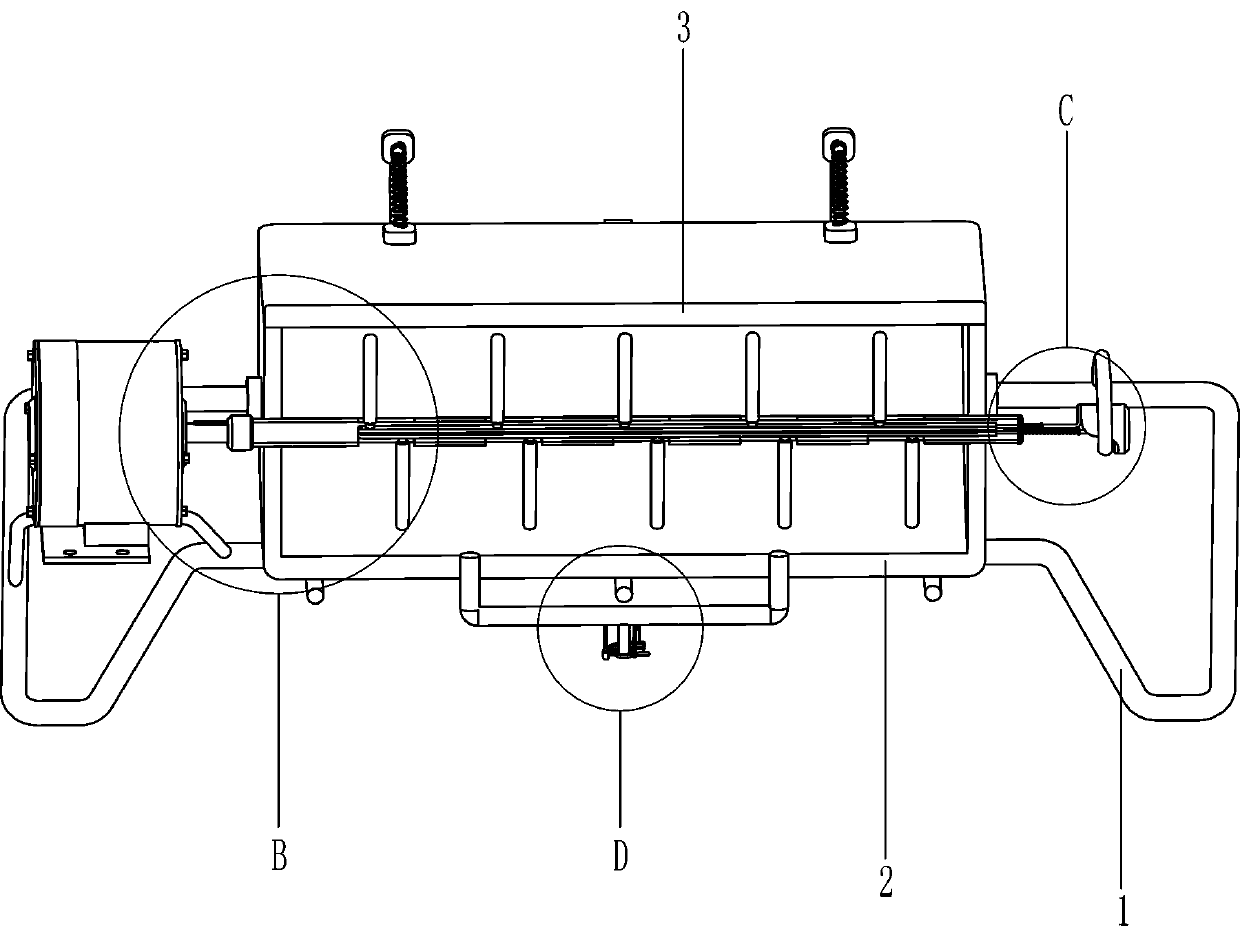

[0023] A stirring and mixing device for paint powder, such as Figure 1-6 As shown, it includes a support frame 1, a semicircular mixing bucket 2, a cover plate 3, a clamping assembly, a driving assembly, a stirring assembly, and a discharge assembly. Installed on the upper part of the support frame 1, the cover plate 3 is rotatably installed on the top of the semicircular mixing bucket 2, and a clamping assembly is provided between the cover plate 3 and the semicircular mixing bucket 2 by sliding, and the driving assembly is installed on the support The upper part of the front side of the frame 1 is powered by a motor. The stirring component is installed on the driving component and the semicircular mixing bucket 2, and is stirred by rotation. The discharge component is installed on the bottom of the semicircular mixing bucket 2, and the material is discharged by sliding.

[0024] Such as figure 1 and 3 As shown, the clamping assembly includes a concave block 4, a hook 5, a...

Embodiment 2

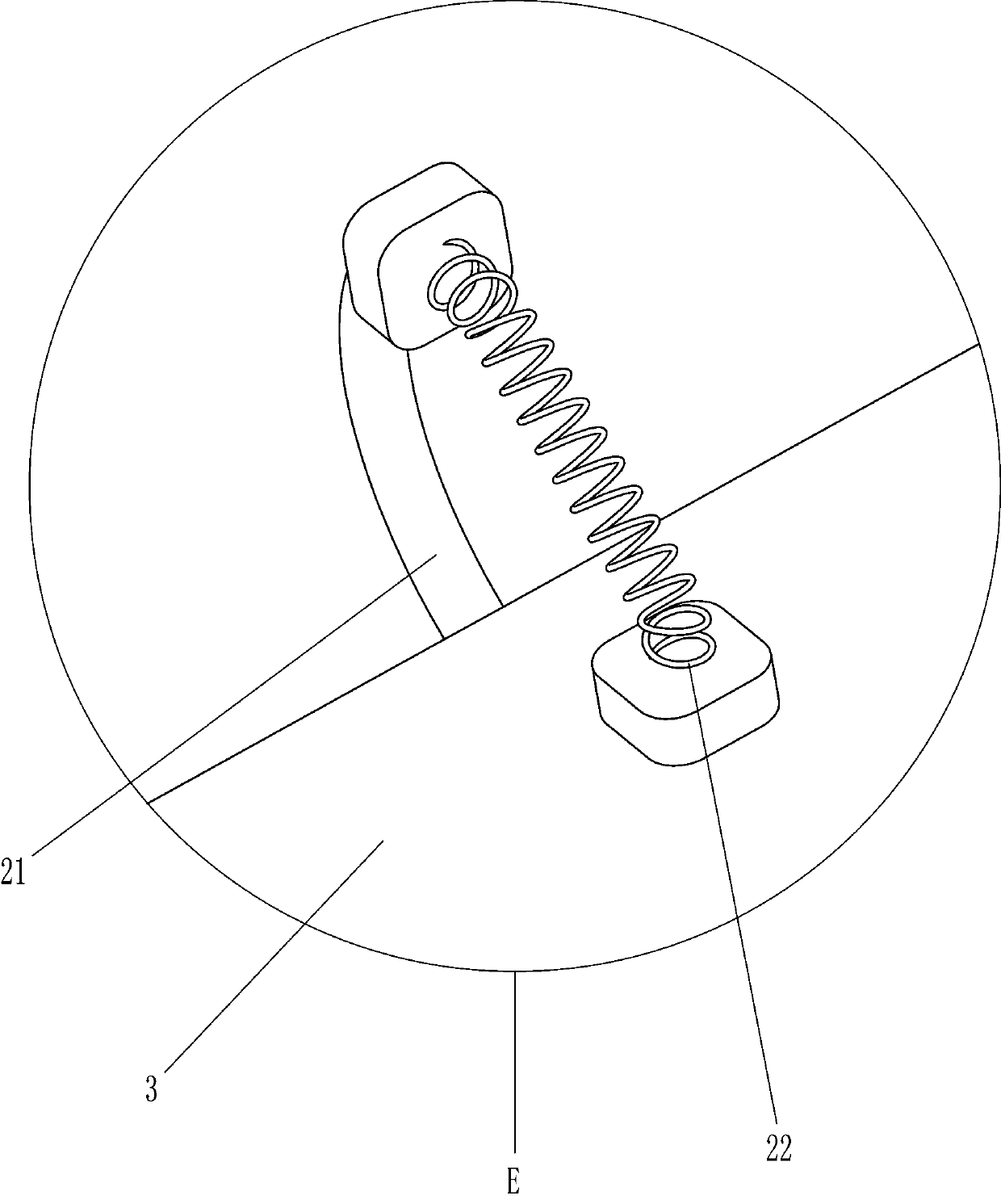

[0034] On the basis of Example 1, such as figure 1 and 7 As shown, it also includes an arc rod 21 and a third spring 22. There are two arc rods 21, which are symmetrically welded on the rear side of the semicircular mixing bucket 2. There are two third springs 22, which are installed on two arc-shaped Between the rod 21 and the cover plate 3, the third spring 22 is in a stretched state.

[0035] The working principle of the above embodiment: when the crossbar 6 is separated from the hook 5, the cover plate 3 is driven to swing upwards and opened under the action of the third spring 22, and after pouring an appropriate amount of raw materials into the semicircular mixing bucket 2, the cover plate is pushed 3 is reset by swinging downward, and the third spring 22 is stretched, so that the cover plate 3 can be opened automatically, saving the step of adding raw materials.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap