nozzle for soot blower

A soot blower and nozzle technology, applied in the field of machinery, can solve the problems of single structure, difficult maintenance, easy oxidation and burning of the rotating nozzle, and achieve the effect of expanding the surface area and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

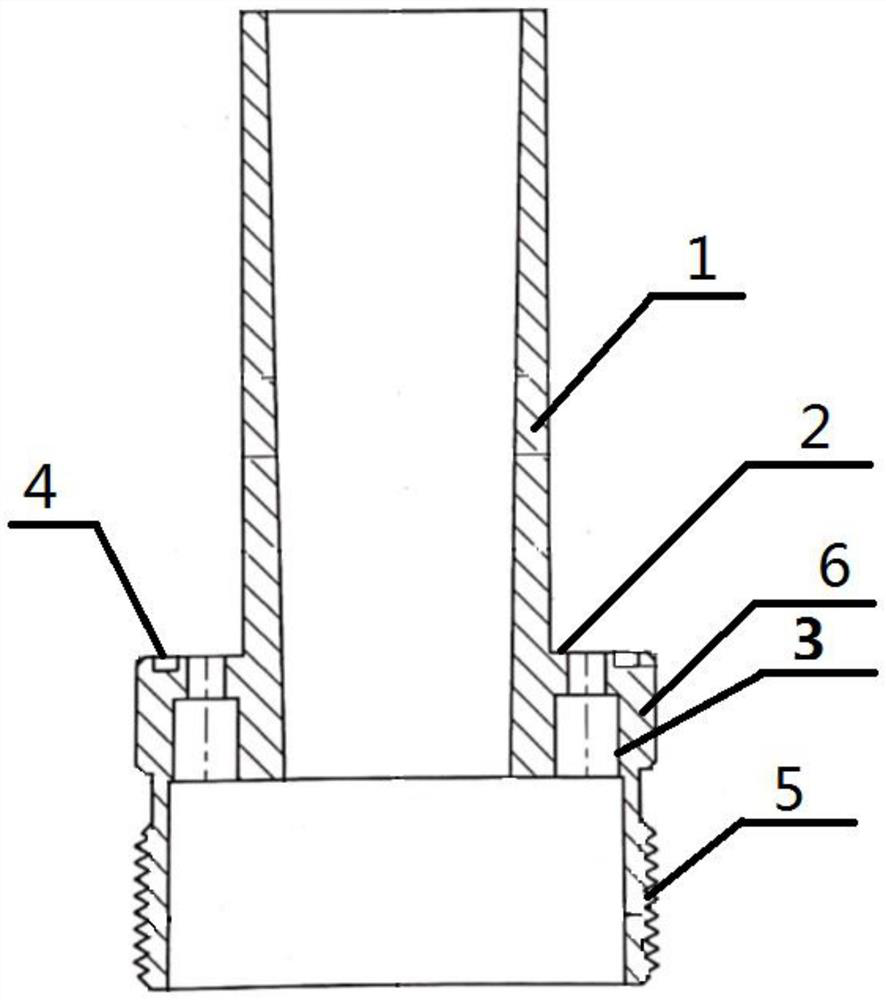

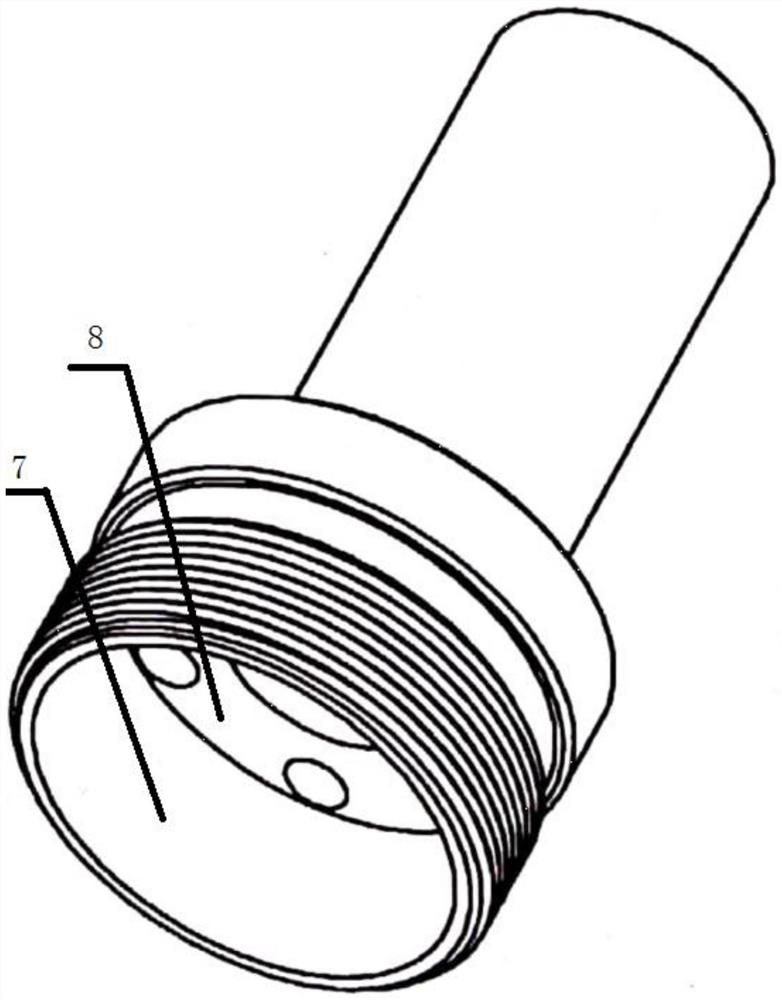

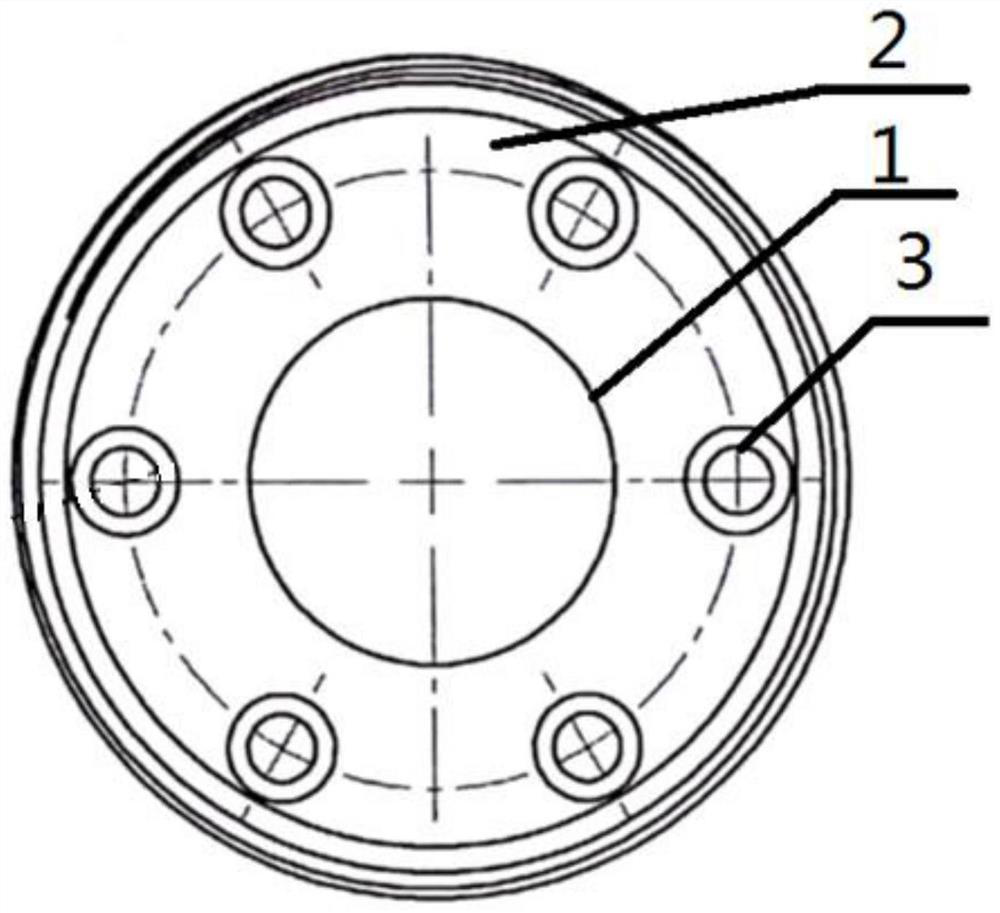

[0017] Such as Figure 1 to Figure 3 As shown, the nozzle for the soot blower includes a nozzle 1, and the nozzle 1 includes a hollow cylindrical nozzle, and there are a plurality of cylindrical nozzles. Distributed in a 360-degree plane range. The inner cavity of the columnar nozzle is trumpet-shaped with a small inside and a large outside, and the inclination angle range of the inner wall of the columnar nozzle is within 15 degrees. The nozzle also includes a circular platform 2 extending outward along the outer periphery of the bottom of the cylindrical nozzle, and nozzles 3 are distributed around the circular platform 2, and the nozzles 3 are trumpet-shaped or stepped holes. Preferably, the stepped holes are in a stepped shape with the bottom being large and the top being small. It also includes a side wall 6 and an O-ring, the side wall 6 is fixed around the round table 2, there are screws 5 on the outer peripheral surface of the side wall 6 for connecting with the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com