Efficient cleaning device for shaft mechanical part machining and manufacturing

A technology of mechanical parts and cleaning devices, which is applied in the direction of cleaning methods using liquids, cleaning methods using tools, and cleaning methods using gas flow, etc., which can solve the problems of inability to clean waste liquid collection, cleaning waste liquid recovery efficiency and recovery effect reduction and other problems to achieve the effect of avoiding the reduction of cleaning efficiency, safe and convenient use, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

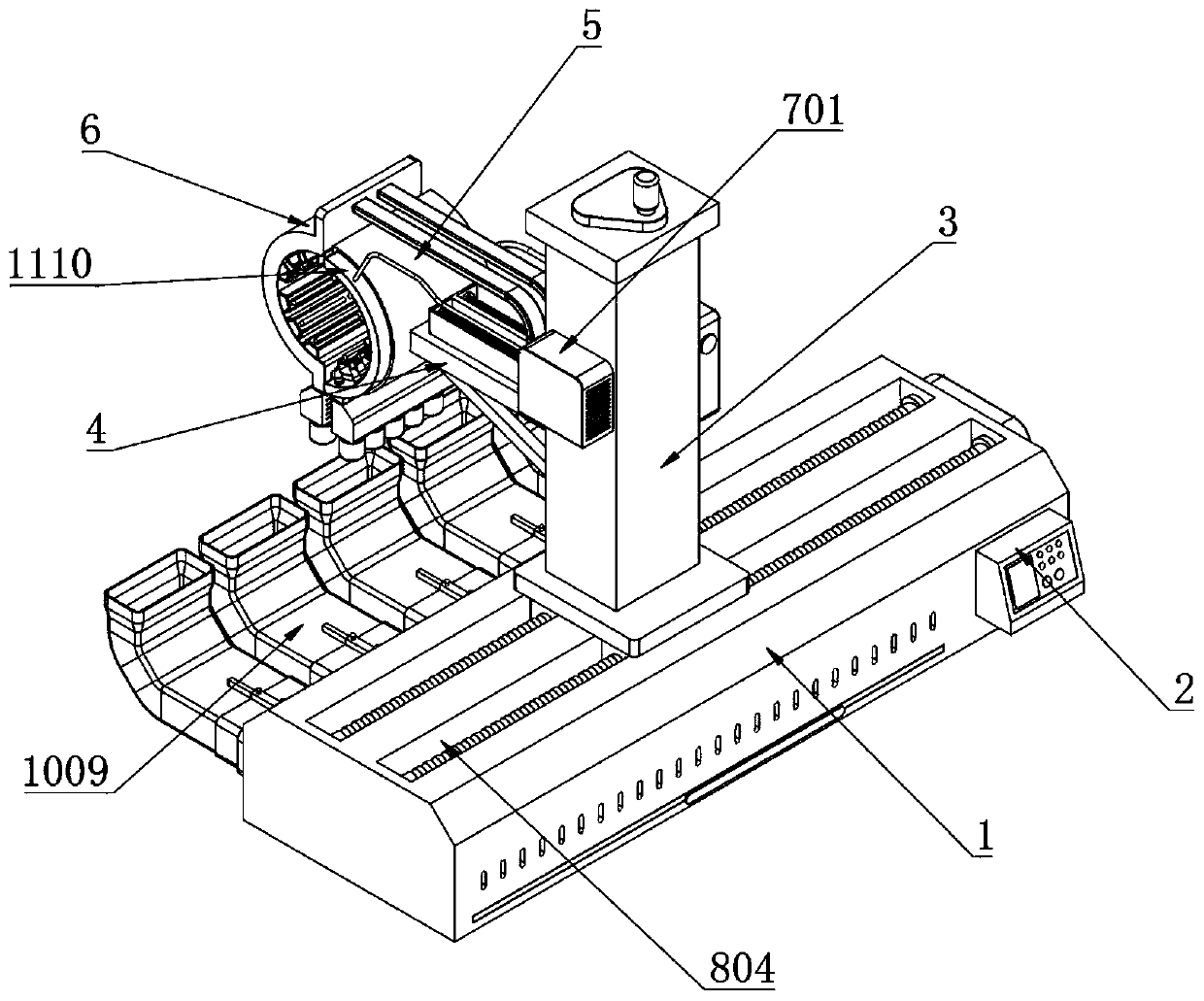

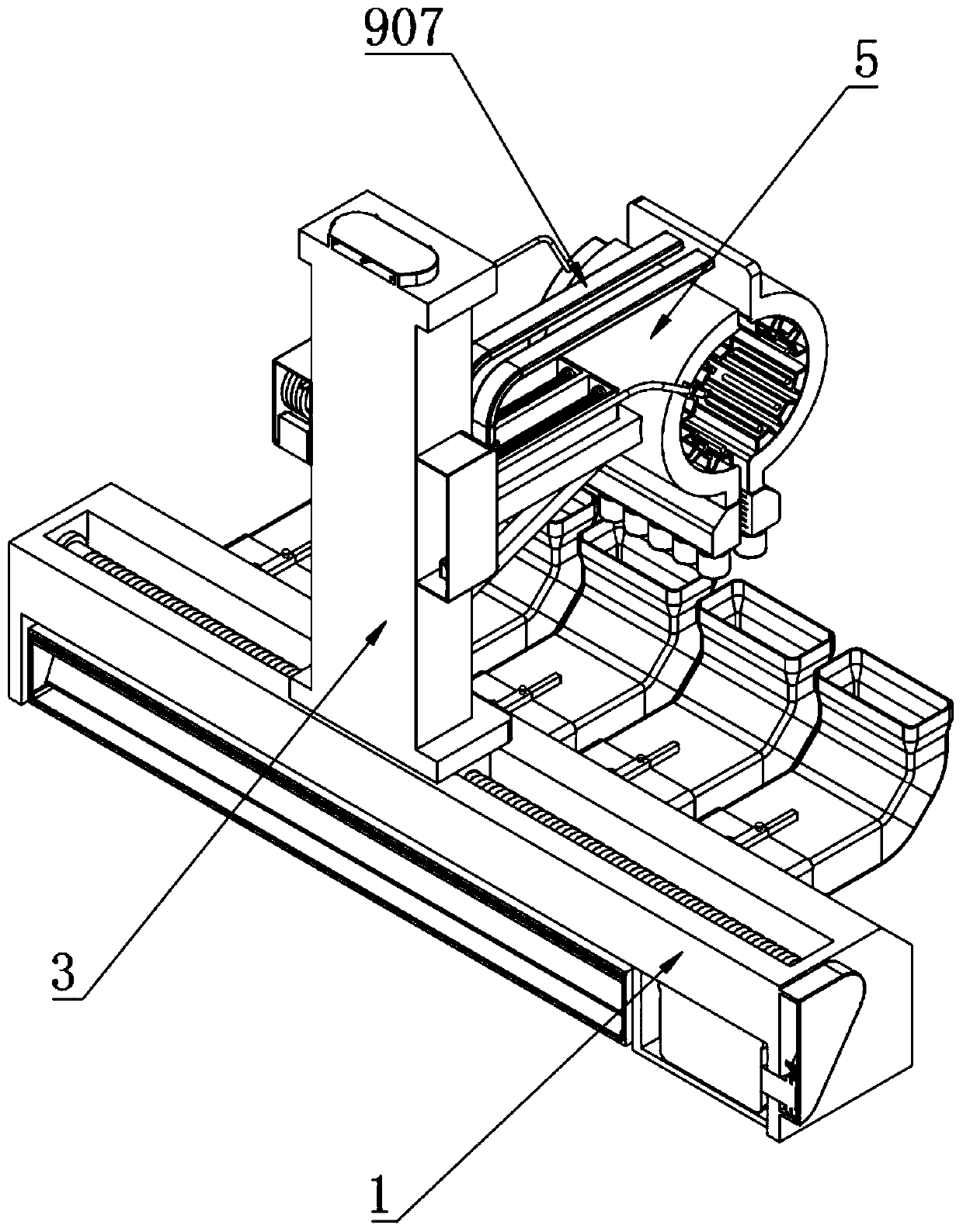

[0058] Example: such as Figure 1-16 As shown, the present invention provides a technical solution, a high-efficiency cleaning device for machining shaft mechanical parts, including a base 1, one end of the base 1 is fixedly connected to a console 2, and a sliding post 3 is installed on the top of the base 1 to slide. One end of the column 3 is slidingly installed with a sliding plate 4, and one end of the sliding plate 4 is fixedly connected with a fixed cleaning side plate 5, and a mobile cleaning side plate 6 is installed at one side of the fixed cleaning side plate 5;

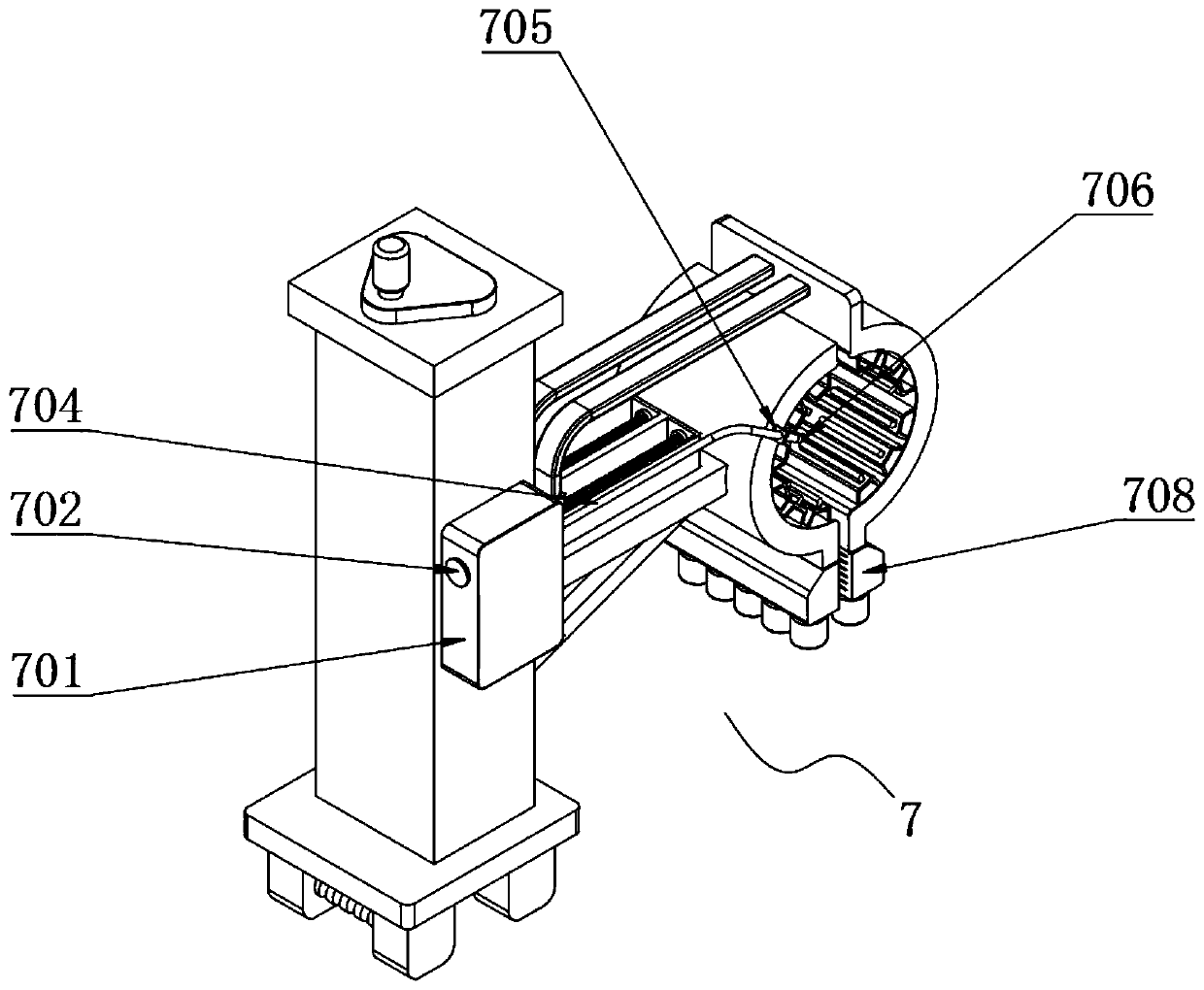

[0059] One end of the sliding column 3 is equipped with a cleaning and collecting mechanism 7, which includes a cleaning liquid storage bin 701, a cleaning liquid adding cover 702, a pressurizing pump 703, a delivery pipe 704, a placement clip 705, a nozzle 706, a barrier side plate 707, Collection bin 708, collection hole 709, filter sponge pad 710, drain hole 711, internal thread mount 712 and collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com